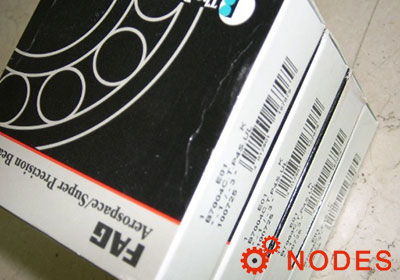

FAG spindle bearings are manufactured under the highest cleanliness conditions and using state-of-the-art washing technologies. Furthermore, their quality is assured by means of 100% “end-ofline” noise testing.

Due to the cleanliness conditions and the preservation methods and agents applied, they can be directly greased and mounted by the end user without the need for additional intermediate cleaning processes. The use of cages guided by the rolling elements in FAG spindle bearings with the suffix P4 allows an increase of up to 30% in the speed of grease distribution.

FAG Spindle bearings with numerous advantages

- higher limiting speeds compared to competitor products

- rapid availability

- minimal noise

- efficient in mounting and commissioning

- new ball-guided polyamide cage TVP

- data matrix code on the bearing: high level of security against counterfeit bearings

- marking of the width tolerance on the bearing and the packaging

- available in numerous sizes: from d=25mm to d=100mm

- for high continuous loads.

Areas of application

- milling spindles in the medium speed range

- main spindles with external drive

- spindles in machining centres

- high speed electric motors.

FAG B70..-TVP-P4 series spindle bearings with a polyamide cage, Fast, Quiet, Efficient

Design of FAG spindle bearing arrangements

Recommendations for the machining tolerances of the shaft and housing as parts adjacent to the bearing

|

Nominal shaft diameter d (mm) |

Deviation for d um |

Cylindricity t1 um |

Flatness t3 um |

Axial runout t4 um |

Coaxiality t5 um |

Mean roughness Ra um |

||

|---|---|---|---|---|---|---|---|---|

| over | incl. | |||||||

| 25 | 30 | 3 | -3 | 1 | 1 | 1.5 | 4 | 0.2 |

| 30 | 50 | 3.5 | -3.5 | 1 | 1 | 1.5 | 4 | 0.2 |

| 50 | 80 | 4 | -4 | 1.2 | 1.2 | 2 | 5 | 0.4 |

| 80 | 100 | 5 | -5 | 1.5 | 1.5 | 2.5 | 6 | 0.4 |

|

Nominal housing bore diameter D (mm) |

Deviation for D um |

Cylindricity t1 um |

Flatness t3 um |

Axial runout t4 um |

Coaxiality t5 um |

Mean roughness Ra um |

||||

|---|---|---|---|---|---|---|---|---|---|---|

| over | incl. | Locating bearing | Non-locating bearing | |||||||

| 25 | 30 | +4 | -2 | +8 | +2 | 1.5 | 1.5 | 2.5 | 4 | 0.4 |

| 30 | 50 | +4 | -3 | +10 | +3 | 1.5 | 1.5 | 2.5 | 4 | 0.4 |

| 50 | 80 | +5 | -3 | +11 | +3 | 2 | 2 | 3 | 5 | 0.4 |

| 80 | 100 | +6 | -4 | +14 | +4 | 2.5 | 2.5 | 4 | 6 | 0.8 |

In order to make comprehensive use of the performance capacity of spindle bearings, the adjacent construction must be of an appropriate design.

Tolerances of the inner and outer ring in FAG spindle bearings, see FAG spindle bearings accuracy, tolerance.

related articles

- FAG spindle bearings accuracy, tolerance

- Contact angle of FAG spindle bearings

- FAG spindle bearing types

- FAG spindle bearings designation

- FAG super precision bearings components and materials

- FAG super precision bearings speeds

- Lubrication of FAG super precision bearings

- Design and applications of FAG super precision bearings

Related numbers

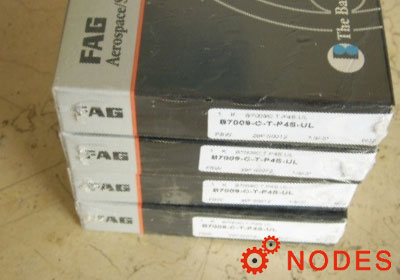

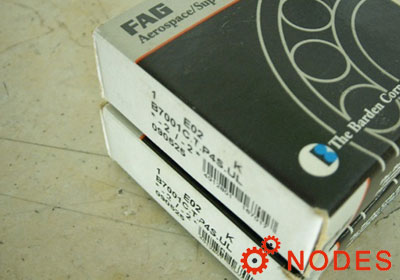

FAG B7001-C-T-P4S bearings

12mm x 28mm x 8mm

FAG B7002-C-T-P4S bearings

15mm x 32mm x 9mm

FAG B7003-C-T-P4S bearings

17mm x 35mm x 10mm

FAG B7004-C-T-P4S bearings

20mm x 42mm x 12mm

FAG B7005-C-T-P4S bearings

25mm x 47mm x 12mm

FAG B7007-C-T-P4S bearings

35mm x 62mm x 14mm

FAG B7008-C-T-P4S bearings

40mm x 68mm x 15mm