Example of Mounting of IKO crossed roller way guides CRWM series

Preparation for mounting IKO crossed roller way guides

Crossed Roller Way is packed by set (1 center way, 2 ways and 2 pairs of roller cages). Be careful not to mix with other sets.

Remove end screws and end stopper, clean up each part with clean wash fluid and then apply rust prevention and lubrication oil.

Cleanup of mounting surface

Remove burrs and blemishes on the machine mounting surface with an oil-stone, etc. Be careful about corner groove on the mounting surface, too.

Wipe off dust and dirt with clean cloth and apply rust prevention and lubrication oil lightly.

Mounting of center way

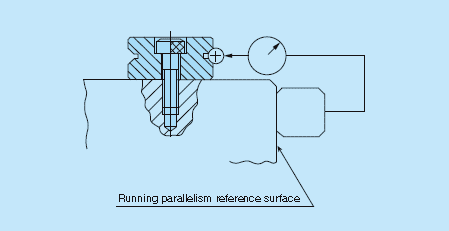

Mounting accuracy check for center way

Roughly align the center way to the mounting surface and lightly fix it with fixing screws.

While measuring mounting parallelism of the center way and raceway to the reference surface of running parallelism for position correction, temporarily tighten the fixing screws to the even tightening torque.

Evenly tighten all the fixing screws to the specified tightening torque.

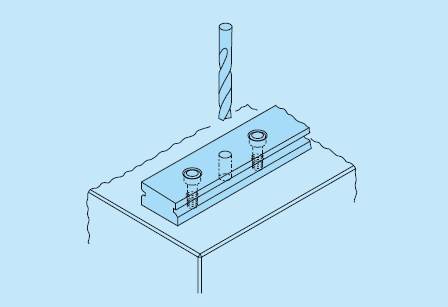

Processing of dowel pin hole

Machining of dowel pin hole

When dowel pins are used, machine holes on the bed in alignment with dowel pin holes near either end of the center way.

Dowel pin hole of the center way is finished for H7. Finish bed holes in the same way.

Diameter and its allowance of dowel pin hole of the center way vary depending on the dimension table.

Eliminate cutting chips and clean up again as necessary. When machines for mounting of the center way are large, clean them up with the center way removed and then reassemble.

Load the dowel pins and check the parallelism of the reference surface of the running parallelism and the raceway of the center way again.

Mounting of table-side way: Follow the mounting of standard type CRW series.Operation of table and bed: Follow the mounting of standard type CRW series.

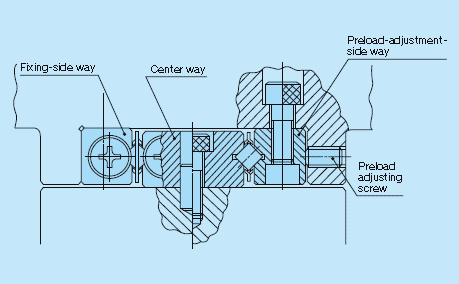

Preload adjustment: Follow the mounting of standard type CRW series.

Full tightening of preload-adjustment-side way: Follow the mounting of standard type CRW series.

Check after assembly: Follow the mounting of standard type CRW series.