INA bearing suffix identify INA bearing components or variants haveing a design and/or features that differ in some respect from the basic design.

The details of suffixes are shown ina the table below, which are sorted by INA bearing type. The table below provides a quick regarding INA bearing suffixes. See each part section for part number designation.

INA insert ball bearings suffix

| Suffix | Description | Design |

|---|---|---|

| AS2/V | Bearing outer ring with 2 lubrication holes in offset planes | Standard |

| B | Bearing with spherical outer ring | |

| 2C | Flinger shields on both sides | |

| FA101 | High and low temperature design –40 °C to +180 °C | |

| FA106 | Bearing subjected to special noise testing | |

| FA107 | Bearing with lubrication holes on the locating side | |

| FA125.5 | With Corrotect® coating, protected against corrosion | |

| FA164 | High temperature design up to +250 °C | |

| KRR | Lip seals on both sides (R type seal) | |

| KLL | Labyrinth seals on both sides (L type seal) | |

| KTT | Triple lip seals on both sides (T type seal) | |

| NR | Slot and snap ring for radial insert ball bearings with cylindrical outer ring | |

| NPP | Lip seals on both sides (P type seal) | |

| OSE | Bearing without locking element (eccentric locking collar) | |

| 2RSR | Lip seals on both sides (vulcanised) | |

| VA | Corrosion-resistant design made from high alloy rolling bearing steel |

Housing units

| Suffix | Description | Design |

|---|---|---|

| 2C | Radial insert ball bearing with flinger shields on both sides | Standard |

| FA101 | High and low temperature design –40 °C to +180 °C | |

| FA106 | Bearing subjected to special noise testing | |

| FA107 | Bearing with lubrication holes on the locating side | |

| FA125 | With Corrotect® coating | |

| FA164 | High temperature design up to +250 °C | |

| N | Cast iron housing with undercut slot for end caps | |

| OSE | Bearing without clamping element | |

| JIS | Housing dimensions according to JIS B 1559 |

INA cylindrical roller bearings suffix

Single row full complement cylindrical roller bearings

| Suffix | Description | Design |

|---|---|---|

| BR | Black oxide coated | Available by agreement |

| C3 | Radial internal clearance larger than normal | |

| C4 | Radial internal clearance larger than C3 | |

| C5 | Radial internal clearance larger than C4 | |

| E | Increased capacity design | Standard depending on series, see dimension table |

| TB | Bearing with increased axial load carrying capacity | Standard depending on bearing size, see dimension table |

Double row cylindrical roller bearings

Available designs of SL01, SL02, SL1850 INA roller bearings

| Suffix | Description | Design |

|---|---|---|

| BR | Black oxide coated | Available by agreement |

| C3 | Radial internal clearance larger than normal | |

| C4 | Radial internal clearance larger than C3 | |

| C5 | Radial internal clearance larger than C4 | |

| TB | Bearing with increased axial load carrying capacity |

Available designs of cable sheave INA bearings

|

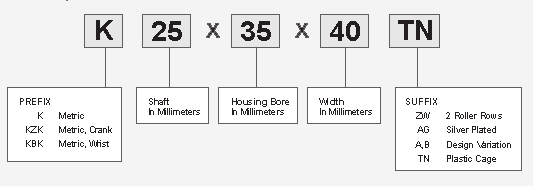

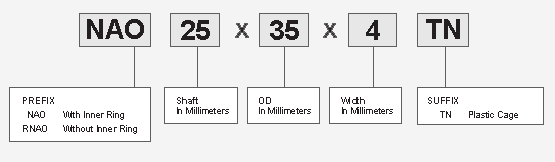

INA needle roller bearings suffix

INA needle roller and cage assemblies

| Suffix | Description | Design |

|---|---|---|

| TV |

Cage made from glass fibre reinforced polyamide 66 - Bearings with plastic cage: see dimension table |

Standard |

| ZW | Double row design (certain sizes only) |

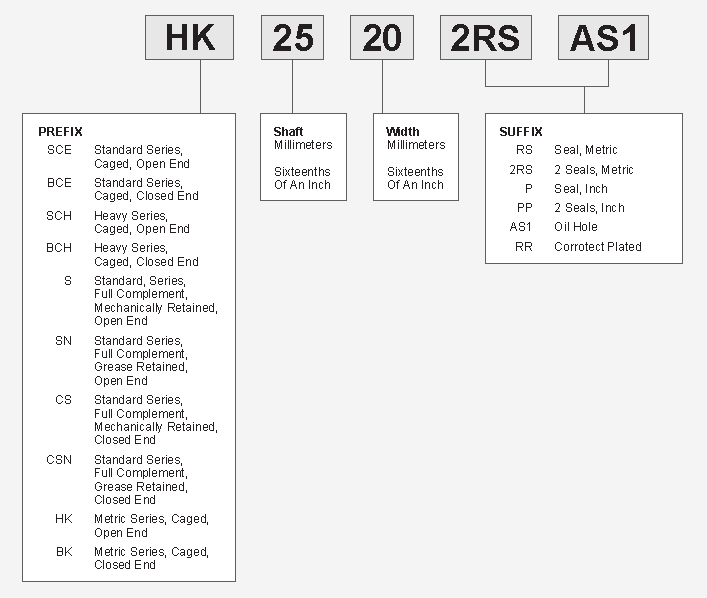

INA drawn cup needle roller bearings

| Suffix | Description | Design |

|---|---|---|

| AS1 | With lubrication hole from HK0609 |

Special design, available by - agreement only |

| GA08 |

Unsealed, greased bearings for operating - temperatures from –30 °C to +140 °C |

|

| RS | Contact seal on one side | Standard |

| TV | Cage made from glass fibre reinforced polyamide 66 | |

| ZW | Double row design, with lubrication hole | |

| 2RS | Contact seals on both sides |

INA machined needle roller bearings

Needle roller bearings with ribs

| Suffix | Description | Design |

|---|---|---|

| C3 | Radial internal clearance larger than normal |

Special design, available by agreement |

| P5 | High dimensional and geometrical accuracy | |

| RSR | Contact seal on one side | Standard |

| TV |

Bearing with cage made from glass fibre reinforced polyamide 66 |

|

| ZW | Double row design, dependent on the size | |

| 2RSR | Contact seals on both sides |

INA needle roller bearings without ribs

| Suffix | Description | Design |

|---|---|---|

| ASR1 | Lubrication hole and lubrication groove in the outer ring, dependent on the size | Standard |

| IS1 |

Lubrication hole in the inner ring, dependent on the size |

|

| TV | Bearing with cage made from glass fibre reinforced polyamide 66, dependent on the size | |

| ZW | Double row design, dependent on the size |

INA inner rings

| Suffix | Description | Design |

|---|---|---|

| C3, C4 | Radial internal clearance larger than normal |

Special design, available by agreement |

| C2 | Radial internal clearance smaller than normal | |

| EGS | Surface ground free from spiral marks for rotary shaft seals to DIN 3 760 and DIN 3 761 | |

| IS1 | With lubrication hole | |

| VGS | Machining allowance z on raceway |

INA axial angular contact ball bearings suffix

| Suffix | Description | Design |

|---|---|---|

| PE | Less stringent bearing design | Standard |

| T, TVP | Polyamide cage, guided by balls | |

| 2AP | Axial angular contact ball bearings, matched pair (ZKLN, ZKLF) | |

| 2RS | Contact seals on both sides | |

| 2Z | Gap seals on both sides |

INA thrust cylindrical roller bearings suffix

| Suffix | Description | Design |

|---|---|---|

| M1) | Brass cage | Standard |

| TV1) | Plastic cage made from glass fibre reinforced polyamide 66 | |

| P5 | High dimensional and geometrical accuracy | Special design2) , available by agreement |

- Depending on series and size.

- For axial bearing washers GS, WS.

INA thrust needle roller bearings suffix

| Suffix | Description | Design |

|---|---|---|

| TV | Plastic cage made from glass fibre reinforced polyamide 66 | Standard |

| RR | Corrosion-resistant design, with Corrotect® coating | Special design, available by agreement |

INA combined needle roller bearings suffix

| Suffix | Description | Design |

|---|---|---|

| TV |

Bearing with radial cage made from glass fibre reinforced polyamide 66 |

Standard |

| Z |

Bearing with end cap Axial bearing component greased with lithium complex soap grease to GA08 |

axial/radial bearings

| Suffix | Description | Design |

|---|---|---|

| H1 ... |

Reduced tolerance on mounting dimension H1 (postscript: H1 with tolerance ± ...) |

Special design, available by agreement |

| H2 ... |

Reduced tolerance on mounting dimension H2 (postscript: H2 with tolerance ± ...) |

|

| - |

Axial and radial runout tolerances restricted by 50% (additional text: axial/radial runout 50%) |

Needle roller/axial cylindrical roller bearings

| Suffix | Description | Design |

|---|---|---|

| L | Extended, stepped shaft locating washer | Standard |

| TV | Cages made from glass fibre reinforced polyamide 66 |

INA crossed roller bearings suffix

| Suffix | Description | Design |

|---|---|---|

| RR | Corrosion-resistant design, with Corrotect® coating | Special design, available by agreement |

| RLO | Low clearance | Standard |

| VSP | Preloaded |

INA sealing rings suffix

| Suffix | Description | Design |

|---|---|---|

| FPM |

Sealing rings G and GR for temperatures from –20 °C to +160 °C or circumferential speeds up to 16 m/s |

Special design, available by agreement |

| HNBR |

Sealing rings G and GR for temperatures from –30 °C to +140 °C or circumferential speeds up to 12 m/s |

INA roller clutches suffix

INA drawn cup roller clutches

| Suffix | Description | Design |

|---|---|---|

| - | Steel pressure springs | Standard |

| KF | Plastic pressure springs | |

| R | Knurled outside surface | |

| RR | Drawn cup roller clutch with Corrotect® coating | Special design, available by agreement |

INA track rollers suffix

Yoke type track rollers

| Suffix | Description | Design |

|---|---|---|

| PP | Plastic axial plain washer with formed seal lip on both sides of the yoke type track roller, giving a three-stage seal | Standard |

| RR | Protected against corrosion by Corrotect® special coating | |

| TV | Plastic cage | |

| 2RS | Protected lip seal on both sides of the yoke type track roller | |

| 2RSR | Radial contact lip seal on both sides of the yoke type track roller | |

| 2ZL | Sealing shield with lamellar rings on both sides of the track roller |

Stud type track rollers

| Suffix | Description | Design |

|---|---|---|

| PP | Plastic axial plain washer with formed seal lip on both sides of the stud type track roller, giving a three-stage seal | Standard |

| RR | Protected against corrosion by Corrotect® special coating | |

| SK | Hexagonal socket only on the flange-side end face, no relubrication facility | |

| 2RS | Protected lip seal on both sides of the stud type track roller |

Ball bearing track rollers

| Suffix | Description | Design |

|---|---|---|

| DRS | Lip seal on the stud side | Standard |

| RR | Protected against corrosion by Corrotect® special coating | Special design, available by agreement |

| X | Cylindrical outside surface | Standard |

| 2RS | Lip seals on both sides, giving axial sealing action | |

| 2RSR | Lip seals on both sides, giving radial sealing action | |

| 2Z | Sealing shields on both sides |