Design of shafts and housings For optimum operation and performance.

Any inaccuracy in the geometry of shafts or housings impairs the function of the bearing. The optimum design of matching parts and precise assembly are therefore important prerequisites for the full performance of the bearing.

Accuracy of the shaft shoulder

Perpendicular inaccuracies of the shaft shoulder can result in an offset between the inner and outer rings of the bearing, causing increased loading on the edges. This shortens the bearing life. It may also cause the cage to break or wear. In order to support the bearing, the housing must be dimensionally stable. The high level of rigidity is also advantageous with regard to noise generation and load distribution.

Under normal operating conditions, it is sufficient if the surface for the fit is turned or precisely drilled. Low-noise and low-vibration applications or high loads, however, require ground surfaces.

If two or more bearings are installed in a single housing, the surfaces of the housing bore for the fit should be designed to allow them to be machined in a single step.

The design and mating of split housings must be precise enough to prevent deformation of the outer bearing rings.

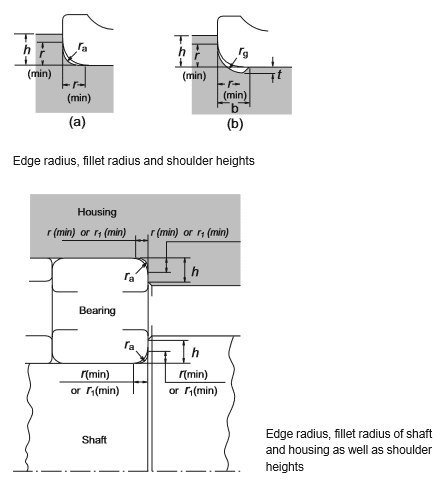

Accuracy of the shoulder and fillet radii

1. Radial bearings

For radial bearings, the shaft and housing shoulders must be high enough to adequately support the bearing face. The ring surface should project beyond the shoulder to allow the use of bearing pullers. It is especially important for tapered roller bearings and cylindrical roller bearings, which are subjected to high axial loads, that the shoulder height (h) be large enough to provide sufficient support for the bearing faces.

The bearing rings must not overlap the fillets of the shaft or the housing. The largest fillet radius ra of the shaft or the housing must be smaller than the smallest edge radius r(min) or r1(min) of the bearing ring.

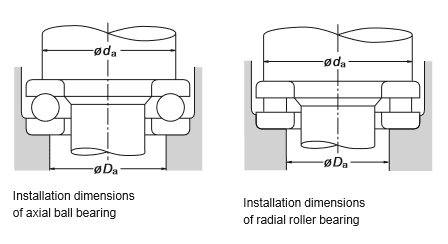

For thrust bearings, attention must be paid to the perpendicularity and location of the supporting surfaces. For axial ball bearings, the diameter of the housing shoulder Da should be less than the pitch circle diameter of the balls, and the diameter of the shaft shoulder da should be greater than the pitch circle diameter of the balls. For axial roller bearings, it is recommended that the shaft and housing shoulders support the entire contact length between the rollers and the rings.

3. Tapered roller bearing

The shoulders of shafts or housings that support the bearing face must be perpendicular to the shaft surface or the housing bore. For tapered roller bearings, the clearance on both sides of the bearing must be sufficient to ensure that there is no contact between the cage and the housing.