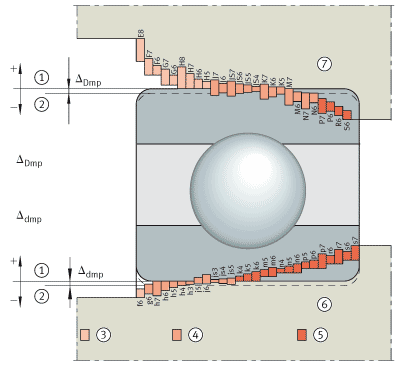

The fit is determined by the ISO tolerances for shafts and housings (ISO 286) in conjunction with the tolerances Δdmp for the bore and ΔDmp for the outside diameter of the bearings (DIN 620).

Tolerance zones

The ISO tolerances are defined in the form of tolerance zones. They are determined by their position relative to the zero line (= tolerance position) and their size (= tolerance grade, see ISO 286). The tolerance position is indicated by letters (upper case for housings, lower case for shafts). For a schematic representation of the most common rolling bearing fits.

Fits for rolling bearings

(1)Zero line

(2)Nominal diameter

(3)Medias/00016412_mei_in_0k_0k.gif Loose fit

(4)Transition fit

(5)Tight fit

(6)Shaft diameter

(7)Housing bore

ΔDmp = tolerance for bearing outside diameter

Δdmp = tolerance for bearing bore

Reference to tables of shaft and housing tolerances

The tables as below contain recommendations for the selection of shaft and housing tolerances that are valid for normal fitting and operating conditions.

Deviations are possible if particular requirements apply, for example in relation to running accuracy, smooth running or operating temperature. Increased running accuracies thus require closer tolerances such as tolerance grade 5 instead of 6. If the inner ring is warmer than the shaft during operation, the seating may loosen to an impermissible extent. A tighter fit must then be selected, for example m6 instead of k6.

In such cases, the question of fits can only be resolved by a compromise. The individual requirements must be weighed against each other and those fulfilled that give the best overall solution.

Shaft tolerances for radial bearings with cylindrical bore

| Condition of rotation | Bearing type |

Shaft diameter mm |

Displacement facility Load |

Tolerance zone |

| Point load on inner ring | Ball bearings, roller bearings | All sizes | Inner ring easily displaced | g6 (g5) |

| Inner ring not easily displaced, angular contact ball bearings and tapered roller bearings with adjusted inner ring | h6 (j6) | |||

| Needle roller bearings | All sizes | Non-locating bearing | h6 (g6)1) | |

|

Circum‑ ferential load on inner ring or indeter- minate load direction |

Ball bearings | up to 50 | Normal loads2) | j6 (j5) |

| 50 to 100 | Low loads3) | j6 (j5) | ||

| Normal and high loads4) | k6 (k5) | |||

| 100 to 200 | Low loads2) | k6 (m6) | ||

| Normal and high loads5) | m6 (m5) | |||

| over 200 | Low loads | m6 (m5) | ||

| Normal and high loads | n6 (n5) | |||

| Roller bearings | up to 60 | Low loads | j6 (j5) | |

| Normal and high loads | k6 (k5) | |||

| 60 to 200 | Low loads | k6 (k5) | ||

| Normal loads | m6 (m5) | |||

| High loads | n6 (n5) | |||

| 200 to 500 | Normal loads | m6 (n6) | ||

| High loads, shocks | p6 | |||

| over 500 | Normal loads | n6 (p6) | ||

| High loads | p6 | |||

| Needle roller bearings | up to 50 | Low loads | k6 | |

| Normal and high loads | m6 | |||

| 50 to 120 | Low loads | m6 | ||

| Normal and high loads | n6 | |||

| 120 to 250 | Low loads | n6 | ||

| Normal and high loads | p6 | |||

| 250 to 400 | Low loads | p6 | ||

| Normal and high loads | r6 | |||

| 400 to 500 | Low loads | r6 | ||

| Normal and high loads | s6 | |||

| over 500 | Low loads | r6 | ||

| Normal and high loads | s6 |

- For easier fitting.

- C/P > 10

- C/P > 12

- C/P < 12

- C/P < 10

Shaft tolerances for axial bearings

| Load | Bearing type | Shaft diameter | Operating conditions | Tolerance zone |

| Axial load | Axial deep groove ball bearings | All sizes | - | j6 |

| Axial deep groove ball bearings, double direction | - | k6 | ||

| Axial cylindrical roller bearings with shaft locating washer | - | h6 (j6) | ||

| Axial cylindrical roller and cage assemblies | - | h8 | ||

| Combined load | Axial spherical roller bearings | All sizes | Point load on shaft locating washer | j6 |

| up to 200 mm | Circumferential load on shaft locating washer | j6 (k6) | ||

| over 200 mm | k6 (m6) |

Housing tolerances radial bearings

| Condition of rotation | Displacement facility Load | Operating conditions | Tolerance zone |

| Point load on outer ring | Outer ring easily displaced, housing unsplit | The tolerance grade is determined by the running accuracy required | H7 (H6)1) |

| Outer ring easily displaced, housing split | H8 (H7) | ||

| Outer ring not easily displaced, housing unsplit | High running accuracy required | H6 (J6) | |

| Outer ring not easily displaced, angular contact ball bearings and tapered roller bearings with adjusted outer ring Housing split | Normal running accuracy | H7 (J7) | |

| Outer ring easily displaced | Heat input via shaft | G72) | |

| Circum‑ ferential load on outer ring or indeter-minate load direction | Low loads, outer ring cannot be displaced | For high running accuracy requirements: K6, M6, N6 and P6 | K7 (K6) |

| Normal loads, shocks, outer ring cannot be displaced | M7 (M6) | ||

| High loads, shocks (C/P < 6), outer ring cannot be displaced | N7 (N6) | ||

| High loads, severe shocks, thin-walled housing, outer ring cannot be displaced | P7 (P6) |

1, G7 for housings made from flake graphite cast iron GG, if bearing outside diameter D > 250 mm and temperature difference between outer ring and housing > 10 K.

2, F7 for housings made from flake graphite cast iron GG, if bearing outside diameter D > 250 mm and temperature difference between outer ring and housing > 10 K.

Housing tolerances for axial bearings

| Load | Bearing type | Operating conditions | Tolerance zone |

| Axial load | Axial deep groove ball bearings | Normal running accuracy High running accuracy |

E8 H6 |

| Axial cylindrical roller bearings with housing locating washer | - | H7 (K7) | |

| Axial cylindrical roller and cage assemblies | - | H10 | |

| Axial spherical roller bearings | Normal loads High loads |

E8 G7 |

|

| Combined loads Point load on housing locating washer | Axial spherical roller bearings | - | H7 |

| Combined loads Circumferential load on housing locating washer | Axial spherical roller bearings | - | K7 |