Schaeffler Group introduced the "Expanded calculation of the adjusted rating life" in 1997. This method was standardised for the first time in DIN ISO 281 Appendix 1 and has been a constituent part of the international standard ISO 281 since 2007.

The basis of the rating life calculation in accordance with ISO281 is lundberg and Palmgren's fatigue theory which always gives a final rating life.

However, modern, high quality FAG bearings can exceed by a considerable margin the values calculated for the basic rating life under favourable operating conditions. Ioannides and Harris have developed a further model for fatigue in rolling contact that expands on the Lundberg and Palmgren theory and gives a better description of the performance capability of modern bearings.

The method “Expanded calculation of the adjusted rating life” takes account of the following influences:

- the bearing load

- the fatigue limit of the material

- the extent to which the surfaces are separated by the lubricant

- the cleanliness in the lubrication gap

- additives in the lubricant

- the internal load distribution and frictional conditions in the bearing.

Calculating dimensioning of FAG rolling bearings

The required size of a FAG bearing is dependent on the demands made on its:

- rating life

- load carrying capacity

- operational reliability.

Dynamic load carrying capacity and life calculator

The dynamic load carrying capacity is described in terms of the basic dynamic load ratings. The basic dynamic load ratings are based on DIN ISO 281.

The term dynamic indicates that the operating condition is with the bearing rotating. This is not a variable load. carrying capacity is described in terms of the basic dynamic load rating and the basic rating life.

The fatigue life is dependent on:

- the load

- the operating speed

- the statistical probability of the first appearance of failure.

The basic dynamic load rating C applies to rotating rolling bearings. It is:

- a constant radial load Cr for radial bearings

- a constant, concentrically acting axial load Ca for axial bearings.

The rating life of FAG bearing calculator

Basic rating life

Rating life in revolutions

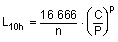

Rating life in operating hours

| L10 | 106 |

| The basic rating life in millions of revolutions, that is reached or exceeded by 90% of a sufficiently large number of apparently identical bearings before the first indications of material fatigue appear | |

| L10h | h |

| The basic rating life in operating hours, that is reached or exceeded by 90% of a sufficiently large number of apparently identical bearings before the first indications of material fatigue appear | |

| C | N |

| Basic dynamic load rating, see FAG bearing size chart | |

| P | N |

| Equivalent dynamic bearing load | |

| p | |

| Life exponent; for roller bearings: p = 10/3 for ball bearings: p = 3 | |

| n | min-1 |

| Operating speed (nominal speed). | |

Equivalent dynamic bearing load

The equivalent dynamic load P on a FAG bearing subjected to combined load (with a radial and axial load) is calculated in accordance with

| P | N |

| Equivalent dynamic radial bearing load | |

| Fr | N |

| Radial load | |

| Fa | N |

| Axial load. | |

| X | |

| Radial load factor; | |

| Y | |

| Axial load factor; | |

The calculation in accordance cannot be applied to radial needle roller bearings, axial needle roller bearings and axial cylindrical roller bearings. Combined loads are not permissible with these bearings.

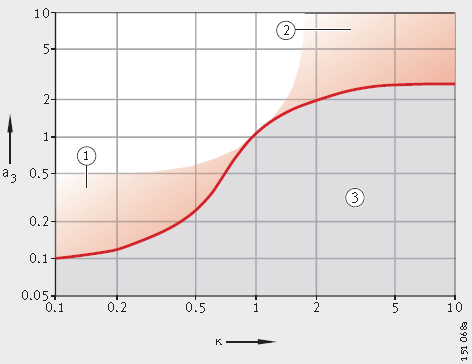

Adjusted rating life

Lna = a1 * a2 * a3 * L10

| Lna | 106 |

| Adjusted rating life for special material characteristics and operating conditions with a requisite reliability of (100 – n) % | |

| L10 | 106 |

| Basic rating life | |

| a1 | |

| Life adjustment factor for a requisite reliability other than 90%. In ISO 281:2007, the values for the life adjustment factor a1 have been redefined | |

| a2 | |

| Life adjustment factor for special material characteristics. For standard FAG rolling bearing steels: a2 = 1 | |

| a3 | |

| Life adjustment factor for special operating conditions; in particular lubrication, Figure below. | |

1, Good cleanliness and suitable additives

2, Very high cleanliness and low load

3, Contamination in the lubricant

a3 = life adjustment factor

k = viscosity ratio

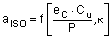

Expanded adjusted rating life

Lnm = a1 * aISO * L10

| Lnm | 106 |

| Expanded adjusted rating life to ISO 281 | |

| L10 | 106 |

| Basic rating life | |

| a1 | |

| Life adjustment factor for a requisite reliability other than 90%. In ISO 281:2007, the values for the life adjustment factor a1 have been redefined | |

| aISO | |

| Life adjustment factor for operating conditions | |

Life adjustment factor a1

| Requisite reliability |

Expanded adjusted rating life |

Life adjustment factor |

|---|---|---|

| % | Lnm | a1 |

| 90 | L10m | 1 |

| 95 | L5m | 0,64 |

| 96 | L4m | 0,55 |

| 97 | L3m | 0,47 |

| 98 | L2m | 0,37 |

| 99 | L1m | 0,25 |

| 99,2 | L0,8m | 0,22 |

| 99,4 | L0,6m | 0,19 |

| 99,6 | L0,4m | 0,16 |

| 99,8 | L0,2m | 0,12 |

| 99,9 | L0,1m | 0,093 |

| 99,92 | L0,08m | 0,087 |

| 99,94 | L0,06m | 0,08 |

| 99,95 | L0,05m | 0,077 |

Life adjustment factor aISO

The standardised method for calculating the life adjustment factor aISO essentially takes account of:

- the load on the bearing

- the lubrication conditions (viscosity and type of lubricant, speed, bearing size, additives)

- the fatigue limit of the material

- the type of bearing

- the residual stress in the material

- the environmental conditions

- contamination of the lubricant

| aISO | |

| Life adjustment factor for operating conditions | |

| ec | |

| Life adjustment factor for contamination | |

| Cu | N |

| Fatigue limit load | |

| P | N |

| Equivalent dynamic bearing load | |

| k | |

| Viscosity ratio | |

Guide values for the contamination ec

| Contamination | Contamination factor eC | |||

|---|---|---|---|---|

| dM < 100 mm | dM ≧ 100 mm | |||

| from | to | from | to | |

Very high cleanliness:

|

1 | 1 | ||

High cleanliness:

|

0,8 | 0,6 | 0,9 | 0,8 |

Standard cleanliness:

|

0,6 | 0,5 | 0,8 | 0,6 |

Slight contamination:

|

0,5 | 0,3 | 0,6 | 0,4 |

Typical contamination:

|

0,3 | 0,1 | 0,4 | 0,2 |

Heavy contamination:

|

0,1 | 0 | 0,1 | 0 |

| Very heavy contamination | 0 | 0 | ||

Guide values for dimensioning

The values for the recommended rating life are guide values for normal operating conditions. In addition, the tables give the operating life values that are usually achieved in practice at various mounting locations.

Motor vehicles

| Mounting location | Recommended rating life | |||

|---|---|---|---|---|

| h | ||||

| Ball bearings | Roller bearings | |||

| from | to | from | to | |

| Motorcycles | 400 | 2 000 | 400 | 2 400 |

| Passenger car powertrains | 500 | 1 100 | 500 | 1 200 |

| Passenger car gearboxes protected against contamination | 200 | 500 | 200 | 500 |

| Passenger car wheel bearings | 1 400 | 5 300 | 1 500 | 7 000 |

| Light commercial vehicles | 2 000 | 4 000 | 2 400 | 5 000 |

| Medium commercial vehicles | 2 900 | 5 300 | 3 600 | 7 000 |

| Heavy commercial vehicles | 4 000 | 8 800 | 5 000 | 12 000 |

| Buses | 2 900 | 11 000 | 3 600 | 16 000 |

| Internal combustion engines | 900 | 4 000 | 900 | 5 000 |

Rail vehicles

| Mounting location | Operating life | |

|---|---|---|

| Millions of kilometres | ||

| from | to | |

| Wheelset bearings for freight wagons | 0,1 | 0,1 |

| Urban transport vehicles | 1 | 2 |

| Passenger carriages | 2 | 3 |

| Goods wagons | 1 | 2 |

| Tipper wagons | 1 | 2 |

| Powered units | 2 | 3 |

| Locomotives, external bearings | 2 | 4 |

| Locomotives, internal bearings | 2 | 4 |

| Shunting and industrial locomotives | 0,5 | 1 |

| Gearboxes for rail vehicles | 0,5 | 2 |

Shipbuilding

| Mounting location | Recommended rating life | Operating life | ||||

|---|---|---|---|---|---|---|

| h | h | |||||

| Ball bearings | Roller bearings | |||||

| from | to | from | to | from | to | |

| Marine thrust bearings | - | - | 20 000 | 50 000 | 30 000 | 80 000 |

| Marine shaft bearings | - | - | 50 000 | 200 000 | 30 000 | 80 000 |

| Large marine gearboxes | 14 000 | 46 000 | 20 000 | 75 000 | 30 000 | 80 000 |

| Small marine gearboxes | 4 000 | 14 000 | 5 000 | 20 000 | 5 000 | 20 000 |

| Boat propulsion systems | 1 700 | 7 800 | 2 000 | 10 000 | 2 000 | 10 000 |

Agricultural machinery

| Mounting location | Recommended rating life | Operating life | ||||

|---|---|---|---|---|---|---|

| h | h | |||||

| Ball bearings | Roller bearings | |||||

| from | to | from | to | from | to | |

| Tractors | 1 700 | 4 000 | 2 000 | 5 000 | 5 000 | 10 000 |

| Self-propelled machinery | 1 700 | 4 000 | 2 000 | 5 000 | 2 000 | 6 000 |

| Seasonal machinery | 500 | 1 700 | 500 | 2 000 | 500 | 2 000 |

Construction machinery

| Mounting location | Recommended rating life | Operating life | ||||

|---|---|---|---|---|---|---|

| h | h | |||||

| Ball bearings | Roller bearings | |||||

| from | to | from | to | from | to | |

| Dozers, loaders | 4 000 | 7 800 | 5 000 | 10 000 | 5 000 | 10 000 |

|

Excavators, travelling gear |

500 | 1 700 | 500 | 2 000 | 500 | 2 000 |

| Excavators, slewing gear | 1 700 | 4 000 | 2 000 | 5 000 | 2 000 | 5 000 |

| Vibratory road rollers, unbalance generators | 1 700 | 4 000 | 2 000 | 5 000 | 5 000 | 30 000 |

| Vibrator bodies | 500 | 1 700 | 500 | 2 000 | 500 | 2 000 |

Electric motors

| Mounting location | Recommended rating life | Operating life | |||||

|---|---|---|---|---|---|---|---|

| h | h | ||||||

| Ball bearings | Roller bearings | ||||||

| from | to | from | to | from | to | ||

|

Electric motors for household appliances |

1 700 | 4 000 | - | - | 500 | 1000 | |

| Series motors | 21 000 | 32 000 | 35 000 | 50 000 | 20 000 | 30 000 | |

| Large motors | 32 000 | 63 000 | 50 000 | 110 000 | 40 000 | 50 000 | |

| Wind energy generators | - | - | - | - | 100 000 | 200 000 | |

| Generators | - | - | - | - | 40 000 | 50 000 | |

Rolling mills, steelworks equipment

| Mounting location | Recommended rating life | Operating life | ||||

|---|---|---|---|---|---|---|

| h | h | |||||

| Ball bearings | Roller bearings | |||||

| from | to | from | to | from | to | |

| Rolling mill frames | 500 | 14 000 | 500 | 20 000 | 2 000 | 10 000 |

| Rolling mill gearboxes | 14 000 | 32 000 | 20 000 | 50 000 | 20 000 | 40 000 |

| Roller tables | 7 800 | 21 000 | 10 000 | 35 000 | 20 000 | 40 000 |

| Centrifugal casting machines | 21 000 | 46 000 | 35 000 | 75 000 | 30 000 | 60 000 |

Machine tools

| Mounting location | Recommended rating life | Operating life | ||||

|---|---|---|---|---|---|---|

| h | h | |||||

| Ball bearings | Roller bearings | |||||

| from | to | from | to | from | to | |

| Headstock spindles, milling spindles | 14 000 | 46 000 | 20 000 | 75 000 | 10 000 | 30 000 |

| Drilling spindles | 14 000 | 32 000 | 20 000 | 50 000 | 1 000 | 20 000 |

| External grinding spindles | 7 800 | 21 000 | 10 000 | 35 000 | 10 000 | 20 000 |

| Hole grinding spindles | - | 500 | 2 000 | |||

|

Workpiece spindles in grinding machines |

21 000 | 63 000 | 35 000 | 110 000 | 20 000 | 30 000 |

| Machine tool gearboxes | 14 000 | 32 000 | 20 000 | 50 000 | 10 000 | 20 000 |

| Presses, flywheels | 21 000 | 32 000 | 35 000 | 50 000 | 20 000 | 30 000 |

| Presses, eccentric shafts | 14 000 | 21 000 | 20 000 | 35 000 | 10 000 | 20 000 |

| Electric tools and compressed air tools | 4 000 | 14 000 | 5 000 | 20 000 | 100 | 200 |

Woodworking machinery

| Mounting location | Recommended rating life | Operating life | ||||

|---|---|---|---|---|---|---|

| h | h | |||||

| Ball bearings | Roller bearings | |||||

| from | to | from | to | from | to | |

| Milling spindles and cutter blocks | 14 000 | 32 000 | 20 000 | 50 000 | 10 000 | 20 000 |

|

Saw frames, main bearings |

- | - | 35 000 | 50 000 | - | |

|

Saw frames, connecting rod bearings |

- | - | 10 000 | 20 000 | - | |

| Circular saws | 4 000 | 14 000 | 5 000 | 20 000 | 10 000 | 20 000 |

Gearboxes in general machine building

| Mounting location | Recommended rating life | Operating life | ||||

|---|---|---|---|---|---|---|

| h | h | |||||

| Ball bearings | Roller bearings | |||||

| from | to | from | to | from | to | |

| Universal gearboxes | 4 000 | 14 000 | 5 000 | 20 000 | 5 000 | 20 000 |

| Geared motors | 4 000 | 14 000 | 5 000 | 20 000 | 5 000 | 20 000 |

| Large gearboxes, stationary | 14 000 | 46 000 | 20 000 | 75 000 | 20 000 | 80 000 |

Conveying equipment

| Mounting location | Recommended rating life | Operating life | ||||

|---|---|---|---|---|---|---|

| h | h | |||||

| Ball bearings | Roller bearings | |||||

| from | to | from | to | from | to | |

| Belt drives, mining | - | - | 75 000 | 150 000 | 10 000 | 30 000 |

| Conveyor belt rollers, mining | 46 000 | 63 000 | 75 000 | 110 000 | 10 000 | 30 000 |

| Conveyor belt rollers, general | 7 800 | 21 000 | 10 000 | 35 000 | 10 000 | 30 000 |

| Belt drums | - | - | 50 000 | 75 000 | 10 000 | 30 000 |

| Bucket wheel excavators, travel drive | 7 800 | 21 000 | 10 000 | 35 000 | 5 000 | 15 000 |

| Bucket wheel excavators, bucket wheel | - | - | 75 000 | 200 000 | 30 000 | 50 000 |

| Bucket wheel excavators, bucket wheel drive | 46 000 | 83 000 | 75 000 | 150 000 | 30 000 | 50 000 |

| Winding cable sheaves | 32 000 | 46 000 | 50 000 | 75 000 | 50 000 | 80 000 |

| Sheaves | 7 800 | 21 000 | 10 000 | 35 000 | 8 000 | 30 000 |

| Tunnel-boring machines: drill head main bearings | - | - | - | - | 5 000 | 10 000 |

Pumps, fans, compressors

| Mounting location | Recommended rating life | Operating life | ||||

|---|---|---|---|---|---|---|

| h | h | |||||

| Ball bearings | Roller bearings | |||||

| from | to | from | to | from | to | |

| Ventilators, fans | 21 000 | 46 000 | 35 000 | 75 000 | 20 000 | 100 000 |

| Large fans | 32 000 | 63 000 | 50 000 | 110 000 | 10 000 | - |

| Piston pumps | 21 000 | 46 000 | 35 000 | 75 000 | 20 000 | 50 000 |

| Centrifugal pumps | 14 000 | 46 000 | 20 000 | 75 000 | 20 000 | 50 000 |

|

Hydraulic axial and radial piston engines |

500 | 7 800 | 500 | 10 000 | 1 000 | 20 000 |

| Gear pumps | 500 | 7 800 | 500 | 10 000 | 1 000 | 20 000 |

| Compressors | 4 000 | 21 000 | 5 000 | 35 000 | 30 000 | 80 000 |

Centrifuges, stirrers

| Mounting location | Recommended rating life | Operating life | ||||

|---|---|---|---|---|---|---|

| h | h | |||||

| Ball bearings | Roller bearings | |||||

| from | to | from | to | from | to | |

| Centrifuges | 7 800 | 14 000 | 10 000 | 20 000 | 40 000 | 60 000 |

| Large stirrers | 21 000 | 32 000 | 35 000 | 50 000 | 40 000 | 50 000 |

Textile machinery

| Mounting location | Recommended rating life | Operating life | ||||

|---|---|---|---|---|---|---|

| h | h | |||||

| Ball bearings | Roller bearings | |||||

| from | to | from | to | from | to | |

| Spinning machines, spinning spindles | 21 000 | 46 000 | 35 000 | 75 000 | 10 000 | 50 000 |

|

Weaving and knitting machines |

14 000 | 32 000 | 20 000 | 50 000 | ||

Plastics processing

| Mounting location | Recommended rating life | Operating life | ||||

|---|---|---|---|---|---|---|

| h | h | |||||

| Ball bearings | Roller bearings | |||||

| from | to | from | to | from | to | |

| Plastics worm extruders | 14 000 | 21 000 | 20 000 | 35 000 | 20 000 | 100 000 |

|

Rubber and plastics calenders |

21 000 | 46 000 | 35 000 | 75 000 | ||

Crushers, mills, screens

| Mounting location | Recommended rating life | Operating life | ||||

|---|---|---|---|---|---|---|

| h | h | |||||

| Ball bearings | Roller bearings | |||||

| from | to | from | to | from | to | |

| Jaw crushers | - | - | 20 000 | 35 000 | 25 000 | 40 000 |

|

Gyratory crushers, roll crushers |

- | - | 20 000 | 35 000 | ||

|

Rigid hammer mills, hammer mills, impact crushers |

– | – | 50 000 | 110 000 | 40 000 | 40 000 |

| Tube mills | - | - | 50 000 | 100 000 | 100 000 | 100 000 |

| Vibration grinding mills | - | - | 5 000 | 20 000 | 30 000 | 60 000 |

| Grinding track mills | - | - | 50 000 | 110 000 | 60 000 | 100 000 |

| Vibrating screens | - | - | 10 000 | 20 000 | 10 000 | 30 000 |

| Briquette presses | - | - | 35 000 | 50 000 | 40 000 | 40 000 |

|

Rotary kiln radial support rollers |

- | - | 50 000 | 110 000 | 100 000 | - |

| Roller presses | - | - | - | - | 40 000 | 40 000 |

Paper and printing machinery

| Mounting location | Recommended rating life | Operating life | |||||

|---|---|---|---|---|---|---|---|

| h | h | ||||||

| Ball bearings | Roller bearings | ||||||

| from | to | from | to | from | to | ||

|

Paper machinery, wet section |

- | - | 110 000 | 150 000 | 50 000 | 100 000 | |

|

Paper machinery, dry section |

- | - | 150 000 | 250 000 | - | ||

| Guide rolls | 50 000 | 120 000 | |||||

| Dryer rolls | 50 000 | 150 000 | |||||

| M.G. cylinders | 50 000 | 200 000 | |||||

|

Paper machinery, refiners |

- | - | 80 000 | 120 000 | 50 000 | 100 000 | |

| Paper machinery, calenders | - | - | 80 000 | 110 000 | 50 000 | 100 000 | |

| Printing machinery | 32 000 | 46 000 | 50 000 | 75 000 | 30 000 | 60 000 | |

Static load carrying capacity calculator

If high, static or shock loads occur, the raceways and rolling elements may undergo plastic deformation. This deformation limits the static load carrying capacity of the FAG rolling bearing with respect to the permissible noise level during operation of the bearing.

If a rolling bearing operates with only infrequent rotary motion or completely without rotary motion, its size is determined in accordance with the basic static load rating C0.

In accordance with DIN ISO 76, this is:

- a constant radial load C0r for radial bearings

- a constant, concentrically acting axial load C0a for axial bearings.

The basic static load rating C0 is that load under which the Hertzian pressure at the most heavily loaded point between the rolling elements and raceways reaches the following values:

- for roller bearings, 4 000 N/mm2

- for ball bearings, 4 200 N/mm2

- for self-aligning ball bearings, 4 600 N/mm2.

Under normal contact conditions, this load causes a permanent deformation at the contact points of approx. 1/10 000 of the rolling element diameter.

Static load safety factor

S0 = C0 / P0

| S0 | - |

| Static load safety factor; | |

| C0r, C0a | N |

| Basic radial or axial static load; | |

| P0r, P0a | N |

| Radial or axial equivalent static bearing load | |

Static load safety factor S0 for ball and roller beraings

| Operating conditions and application |

Static load safety factor S0 |

|

|---|---|---|

| min. | ||

| Ball bearings | Roller bearings | |

| Low-noise, smooth running, free from vibrations, high rotational accuracy | 2 | 3 |

| Normal, smooth running, free from vibrations, normal rotational accuracy | 1 | 1,5 |

| Pronounced shock loading1) | 1,5 | 3 |

Equivalent static bearing load calculator

The equivalent static load P0 is a calculated value. It corresponds to a radial load in FAG radial bearings and a concentric axial load in axial bearings.

P0 induces the same load at the centre point of the most heavily loaded contact point between the rolling element and raceway as the combined load occurring in practice.

P0 = X0 * Fr + Y0 * Fa

| P0 | N |

| Equivalent static bearing load | |

| X0 | N |

| Radial load factor; | |

| Fr, Fa | N |

| Largest radial or axial load present | |

| Y0 | N |

| Axial load factor | |