In general, shafts are supported by only two bearings. When considering the bearing mounting arrangement, the following items must be investigated:

- Expansion and contraction of the shaft caused by temperature variations.

- Ease of bearing mounting and dismounting.

- Misalignment of the inner and outer rings caused by deflection of the shaft or mounting error.

- Rigidity of the entire system including NSK bearings and preloading method.

- Capability to sustain the loads at their proper positions and to transmit them.

Fixed-End and Free-End Bearings

Among the NSK bearings on a shaft, only one can be a "fixed-end" bearing that is used to fix the shaft axially. For this fixed-end bearing, a type which can carry both radial and axial loads must be selected.

Bearings other than the fixed-end one must be "freeend" bearings that carry only radial loads to relieve the shaft's thermal elongation and contraction.

If measures to relieve a shaft’s thermal elongation and contraction are insufficient, abnormal axial loads are applied to the NSK bearings, which can cause premature failure.

For free-end bearings, NSK cylindrical roller bearings or needle roller bearings with separable inner and outer rings that are free to move axially (NU, N types, etc.) are recommended. When these types are used, mounting and dismounting are also easier.

When non-separable types are used as free-end bearings, usually the fit between the outer ring and housing is loose to allow axial movement of the running shaft together with the NSK bearing. Sometimes, such elongation is relieved by a loose fitting between the inner ring and shaft.

When the distance between the NSK bearings is short and the influence of the shaft elongation and contraction is negligible, two opposed NSK angular contact ball bearings or tapered roller bearings are used. The axial clearance (possible axial movement) after the mounting is adjusted using nuts or shims.

Example of NSK Bearing Arrangements

Some representative bearing mounting arrangements considering preload and rigidity of the entire assembly, shaft elongation and contraction, mounting error, etc. are shown in Table below.

| NSK Bearing Arrangements | Remarks | Application Examples | |

|---|---|---|---|

| Fixed-end | Free-end | ||

|

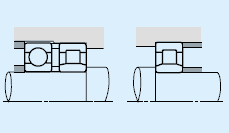

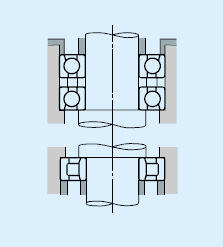

This is a common arrangement in which abnormal loads are not applied to bearings even if the shaft expands or contracts. If the mounting error is small, this is suitable for high speeds. |

Medium size electric motors, blowers | |

|

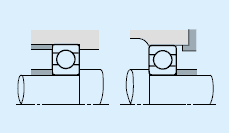

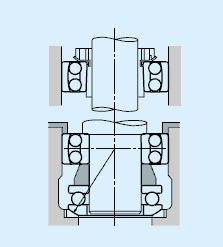

This can withstand heavy loads and shock loads and can take some axial load. Every type of cylindrical roller bearing is separable. This is helpful when interference is necessary for both the inner and outer rings. |

Traction motors for rolling stock | |

|

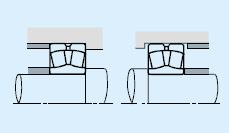

This is used when loads are relatively heavy. For maximum rigidity of the fixed-end bearing, it is a back-to-back type. Both the shaft and housing must have high accuracy and the mounting error must be small. |

Table rollers for steel mills, main spindles of lathes | |

|

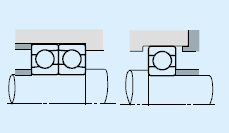

This is also suitable when interference is necessary for both the inner and outer rings. Heavy axial loads cannot be applied. | Calender rolls of paper making machines, axles of diesel locomotives | |

|

This is suitable for high speeds and heavy radial loads. Moderate axial loads can also be applied. It is necessary to provide some clearance between the outer ring of the deep groove ball bearing and the housing bore in order to avoid subjecting it to radial loads. |

Reduction gears in diesel locomotives | |

|

This is the most common arrangement. It can sustain not only radial loads, but moderate axial loads also. |

Double suction volute pumps, automotive transmissions | |

|

This is the most suitable arrangement when there is mounting error or shaft deflection. It is often used for general and industrial applications in which heavy loads are applied. |

Speed reducers, table rollers of steel mills, wheels for overhead travelling cranes | |

|

This is suitable when there are rather heavy axial loads in both directions. Double row angular contact bearings may be used instead of a arrangement of two angular contact ball bearings. |

Worm gear reducers | |

| When there is no distinction between fixed-end and free-end | |||

|

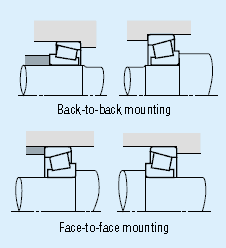

This arrangement is widely used since it can withstand heavy loads and shock loads The back-to-back arrangement is especially good when the distance between bearings is short and moment loads are applied. Face-to-face mounting makes mounting easier when interference is necessary for the inner ring. In general, this arrangement is good when there is mounting error. To use this arrangement with a preload, affection must be paid to the amount of preload and clearance adjustment. |

Pinion shafts of automotive differential gears, automotive front and rear axles, worm gear reducers | |

|

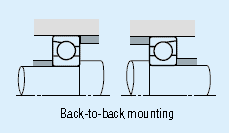

This is used at high speeds when radial loads are not so heavy and axial loads are relatively heavy. It provides good rigidity of the shaft by preloading. For moment loads, back-to-back mounting is better than face-to-face mounting. |

Grinding wheel shafts | |

|

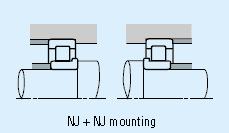

This can withstand heavy loads and shock loads. It can be used if interference is necessary for both the inner and outer rings. Care must be taken so the axial clearance doesn't become too small during running. NF type + NF type mounting is also possible. |

Final reduction gears of construction machines | |

|

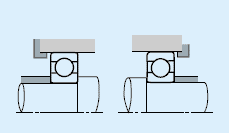

Sometimes a spring is used at the side of the outer ring of one bearing. | Small electric motors, small speed reducers, small pumps | |

| Vertical arrangements | |||

|

Matched angular contact ball bearings are on the fixed end. Cylindrical roller bearing is on the free end. |

Vertical electric motors | |

|

The spherical center of the self-aligning seat must coincide with that of the self-aligning ball bearing. The upper bearing is on the free end. |

Vertical openers (spinning and weaving machines) | |