Limiting speed – Parameters for calculation and use of a correction factor

As soon as a NSK bearing reaches or exceeds its limiting speed – i.e. its empirically established maximum speed – it may no longer be able to operate stably. The limiting speed depends on various factors and can be increased using a correction factor.

The limiting speeds for bearings with grease and oil lubrication are listed in the product tables. These fi gures are based on standard bearings which are exposed to normal loads. Conventional oil-bath lubrication is assumed for bearings with oil lubrication.

Some types of lubrication are not suitable for high speeds. If the rotational speed is more than 70% of the limiting speed listed in the tables, an oil or grease suitable for high speeds must be used.

Conditions and infl uencing factors

The limiting speed is affected by various conditions and infl uencing factors, including:

- Bearing type and size

- Degree of accuracy

- Internal play

- Cage shape and material

- Lubrication

- Load

- Heat dissipation

- Bearing environment

Using a correction factor to adjust the limiting speed

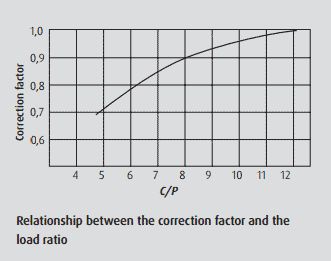

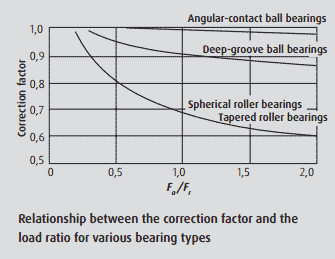

If the above-mentioned conditions have been checked and taken into account, the limiting speed quoted in the product tables must be increased using a correction factor. To do this, the limiting speed is multiplied by a correction factor specific to the bearing in question. The correction factor can only be used if:

a) the bearing load (P) is a maximum of 8% higher than the dynamic load rating (C) or

b) the axial load (Fa) does not exceed the radial load (Fr) by more than 20%.

| Bearing types | Correction factor |

|---|---|

| Cylindrical roller bearings (single row) | 2 |

| Needle roller bearings (except wide series) | 2 |

| Tapered roller bearings | 2 |

| Spherical roller bearings | 1.5 |

| Deep groove ball bearings | 2.5 |

| Angular contact ball bearings (except matched bearings) | 1.5 |