The most common method of applying preload on a NTN bearing is change the relative position of the inner and outer rings of the NTN bearing in the axial direction while applying an axial load between bearings on opposing sides. There are two types of preload: fixed position preload and constant pressure preload.

The basic pattern, purpose and characteristics of bearing preloads are shown in Table below. The fixed position preload is effective for positioning the two NTN bearings and also for increasing the rigidity. Due to the use of a spring for the constant pressure preload, the preloading amount can be kept constantly, even when the distance between the two bearings fluctuates under the influence of operating heat and load.

| Method | Applicable bearings | Object | Characteristics | Applications |

|---|---|---|---|---|

| Fixed position prebad | Angular contact ball bearings | Maintaining accuracy of rotating shaft, preventing vibration increasing rigidity | Preloading is accomplished by a predetermined offset of the rings or by using spacers. | Grinding machines, lathes, milling machines, measuring instruments |

| Tapered roller bearings, thrust ball bearings, angular contact ball bearings | Increasing bearing rigidity | Preload is accomplished by adjusting a threaded screw. The amount of preload is set by measuring the starting torque or axial displacement. | Lathes, milling machines, differential gears of automotives, printing machines, wheel axles | |

| Constant pressure preload | Angular contact ball bearings, deep groove ball bearings, tapered roller bearings (high speed) | Maintaining accuracy and preventing vibration and noise with a constant amount of preload without being affected by loads or temperature | Preloading is accomplished by using coil or belleville springs. | Internal grinding machines, electric motors, high speed shafts in small machines, tension reels |

| Spherical roller thrust bearings, cylindrical roller thrust bearings, thrust ball bearings | Preload is primarily used to prevent smearing of opposite axial load side when bearing an axial load. | Preload is accomplished by using coil or belleville springs. | Rolling mills, extruding machines |

Light and normal preload is applied to prevent general vibration, and medium and heavy preload is applied especially when rigidity is required.

Preload and rigidity

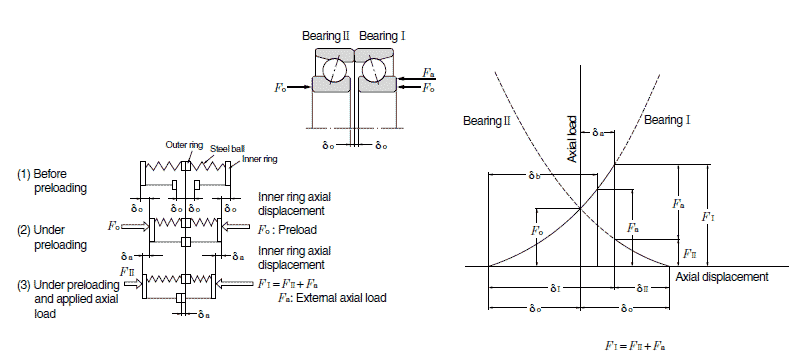

The increased rigidity effect preloading has on bearings is shown in Fig below. When the offset inner rings of the two paired NTN angular contact ball bearings are pressed together, each inner ring is displaced axially by the amount δ0 and is thus given a preload, F0, in the direction. Under this condition, when external axial load Fa is applied, bearing!will have an increased displacement by the amount δa and bearing 2's displacement will decrease. At this time the loads applied to bearing 1 and 2 are F1 and F2, respectively.

Fixed position preload model diagram and preload diagram

Under the condition of no preload, bearing!will be displaced by the amount δb when axial load Fa is applied. Since the amount of displacement, δa, is less than δb, it indicates a higher rigidity for δa.