NTN roller bearing construction

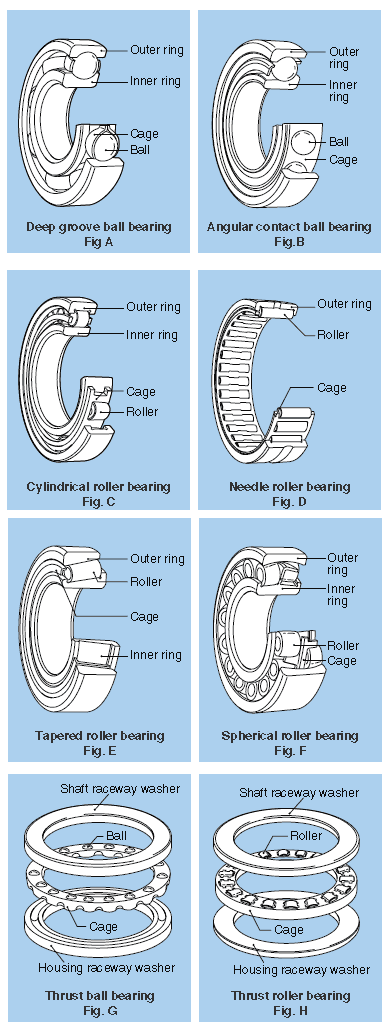

Most rolling bearings consist of rings with raceway (inner ring and outer ring), rolling elements (either balls or rollers) and cage. The cage separates the rolling elements at regular intervals, holds them in place within the inner and outer raceways, and allows them to rotate freely.

Raceway (inner ring and outer ring) or raceway washer

The surface on which rolling elements roll is called the "raceway surface". The load placed on the bearing is supported by this contact surface.

Generally the inner ring fits on the axle or shaft and the outer ring on the housing.

Rolling elements

Rolling elements classify in two types: balls and rollers. Rollers come in four types: cylindrical, needle, tapered, and spherical.

Balls geometrically contact with the raceway surfaces of the inner and outer rings at "points", while the contact surface of rollers is a "line" contact.

Theoretically, rolling bearings are so constructed as to allow the rolling elements to rotate orbitally while also rotating on their own axes at the same time.

Cages

Cages function to maintain rolling elements at a uniform pitch so load is never applied directly to the cage and to prevent the rolling elements from falling out when handling the bearing. Types of cages differ according to way they are manufactured, and include pressed, machined and formed cages.

Classification of NTN rolling bearings

Rolling bearings divide into two main classifications: ball bearings and roller bearings. Ball bearings are classified according to their bearing ring configurations: deep groove type and angular contact type. Roller bearings on the other hand are classified according to the shape of the rollers: cylindrical, needle, tapered and spherical.

NTN Rolling bearings can be further classified according to the direction in which the load is applied; radial bearings carry radial loads and thrust bearings carry axial loads.

Other classification methods include: 1) number of rolling rows (single, double, or 4-row), 2) separable and non-separable, in which either the inner ring or the outer ring can be detached.

There are also bearings designed for special applications, such as: railway car journal roller bearings, ball screw support bearings, turntable bearings, as well as linear motion bearings (linear ball bearings, linear roller bearings and linear flat roller bearings).

Characteristics of NTN rolling bearings

NTN rolling bearings come in many shapes and varieties, each with its own distinctive features.

However, when compared with sliding bearings, NTN rolling bearings all have the following advantages:

The starting friction coefficient is lower and there is little difference between this and the dynamic friction coefficient.

They are internationally standardized, interchangeable and readily obtainable.

They are easy to lubricate and consume less lubricant.

As a general rule, one bearing can carry both radial and axial loads at the same time.

May be used in either high or low temperature applications.

Bearing rigidity can be improved by preloading.

Construction, classes, and special features of rolling bearings are fully described in the boundary dimensions and NTN bearing numbering system section.

NTN Deep groove ball bearings

The most common type of bearing, deep groove ball bearings are widely used in a variety of fields. Deep groove ball bearings include shield bearings and sealed bearings with grease make them easier to use.

Deep groove ball bearings also include bearings with a locating snap-ring to facilitate positioning when mounting the outer ring, expansion compensating bearings which absorb dimension variation of the bearing fitting surface due to housing temperature, and TAB bearings that are able to withstand contamination in the lubricating oil.

NTN Angular contact ball bearings

The line that unites point of contact of the inner ring, ball and outer ring runs at a certain angle (contact angle) in the radial direction. Bearings are generally designed with three contact angles.

Angular contact ball bearings can support an axial load, but cannot be used by single bearing because of the contact angle. They must instead be used in pairs or in combinations.

Angular contact ball bearings include double row angular contact ball bearings for which the inner and outer rings are combined as a single unit. The contact angle of double row angular contact ball bearings is 25°.

There are also four-point contact bearings that can support an axial load in both directions by themselves. These bearings however require caution because problems such as excessive temperature rise and wearing could occur depending on the load conditions.

NTN Cylindrical roller bearings

Uses rollers for rolling elements, and therefore has a high load capacity. The rollers are guided by the ribs of the inner or outer ring. The inner and outer rings can be separated to facilitate assembly, and both can be fit with shaft or housing tightly. If there is no ribs, either the inner or the outer ring can move freely in the axial direction. Cylindrical roller bearings are therefore ideal to be used as so-called "free side bearings" that absorb shaft expansion. In the case where there is a ribs, the bearing can bear a slight axial load between the end of the rollers and the ribs. Cylindrical roller bearings include the HT type which modifies the shape of roller end face and ribs for increasing axial road capacity. And the E type with a special internal design for enhancing radial load capacity. The E type is standardized for small-diameter sizes.

In addition to these, there are cylindrical roller bearings with multiple rows of rollers and the SL type of full complement roller bearing without cage.

NTN Tapered roller bearings

Tapered roller bearings are designed so the inner/outer ring raceway and apex of the tapered rollers intersect at one point on the bearing centerline. By receiving combined load from inner and outer ring, the rollers are pushed against the inner ring rib and roll guided with rib.

Induced force is produced in the axial direction when a radial load is applied, so must be handled by using a pair of bearings. The inner ring with rollers and outer ring come apart, thus facilitating mounting with clearance or preload. Assembled clearance is however hard to manage and requires special attention. Tapered roller bearings are capable of supporting large loads in both the axial and radial directions.

NTN bearings with 4T-, ET-, T- and U attached to the name conform to ISO and JIS standards for sub-unit dimensions (nominal contact angle, nominal small end diameter of outer ring) and are internationally interchangeable.

NTN also has a line of case hardened steel bearings designed for longer life (ETA-, ET-, etc.). NTN tapered roller bearings also include bearings with two and four rows of tapered rollers for extra-heavy loads.

NTN Spherical roller bearings

Equipped with an outer ring with a spherical raceway surface and an inner ring which holds two rows of barrelshaped rolling elements, NTN spherical roller bearings are able to adjust center alignment to handle inclination of the axle or shaft.

There are variety of bearing types that differ according to internal design.

Spherical roller bearings include as type equipped with an inner ring with a tapered bore. The bearing can easily be mounted on a shaft by means of an adapter or withdrawal sleeve. The bearing is capable of supporting heavy loads, and is therefore often used in industrial machinery. When heavy axial load is applied to the bearing, the load on rollers of another row is disappeared, and can cause problems. Attention must therefore be paid to operating conditions.

NTN Thrust bearings

There are many types of thrust bearings that differ according to shape of rolling element and application. Allowable rotational speed is generally low and special attention must be paid to lubrication.

NTN Needle roller bearings

Needle roller bearings use needle rollers as rolling elements. The needle rollers are a maximum of 5 mm in diameter and are 3 to 10 times as long as they are in diameter. Because the bearings use needle rollers as rolling elements, the cross-section is thin, but they have a high load capacity for their size. Because of the large number of rolling elements, the bearings have high rigidity and are ideally suited to wobbling or pivoting motion.

NTN Bearing unit

A unit comprised of a ball bearing inserted into various types of housings. The housing can be bolted onto machinery and the inner ring can be easily mounted on the shaft with a set screw.

This means the bearing unit can support rotating equipment without special design to allow for mounting. A variety of standardized housing shapes is available, including pillow and flange types. The outer diameter of the bearing is spherical just like the inner diameter of the housing, so it capable of aligning itself on the shaft.

NTN roller bearings