When selection NSK bearing types, you should be certain of allowable bearing space, load capacity, permissible speed, misalignment, rigidity, noise, running accuracy. Refer to NSK bearing selection procedure.

Allowable Bearing Space

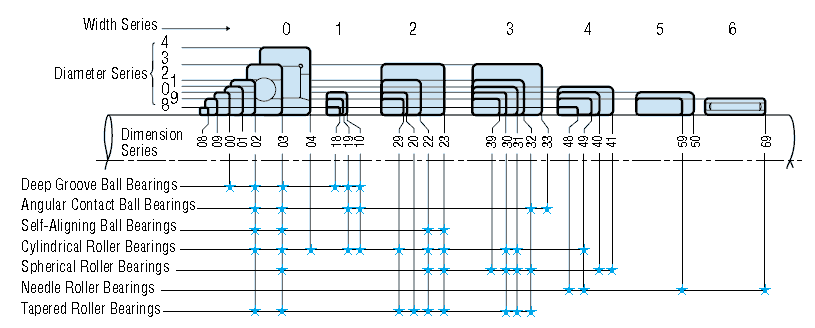

The allowable space for a NSK rolling bearing and its adjacent parts is generally limited so the type and size of the NSK bearing must be selected within such limits. In most cases, the shaft diameter is fixed first by the machine design; therefore, the NSK bearing is often selected based on its bore size. For rolling bearings, there are numerous standardized dimension series and types, and the selection of the optimum bearing from among them is necessary. The below picture shows the dimension series of radial bearings and corresponding bearing types.

Dimension Series of NSK Radial Bearings

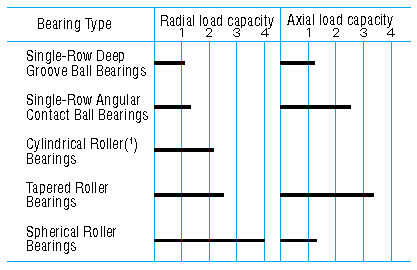

Load Capacity and NSK Bearing Types

The axial load carrying capacity of a NSK bearing is closely related to the radial load capacity in a manner that depends on the bearing design as shown in Fig. below. This figure makes it clear that when NSK bearings of the same dimension series are compared, NSK roller bearings have a higher load capacity than NSK ball bearings and are superior if shock loads exist.

Note(1) The bearings with ribs can take some axial loads.

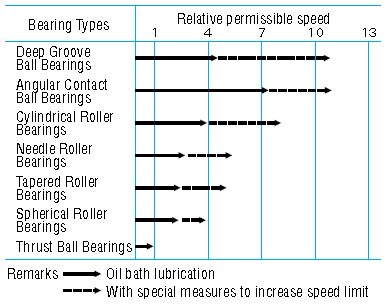

Permissible Speed and NSK Bearing Types

The maximum speed of NSK rolling bearings varies depending, not only the type of bearing, but also its size, type of cage, loads, lubricating method, heat dissipation, etc. Assuming the common oil bath lubrication method, the bearing types are roughly ranked from higher speed to lower as shown in Fig. below.

Relative Permissible Speeds of Various NSK Bearing Types

Misalignment of Inner/Outer Rings and NSK Bearing Types

Because of deflection of a shaft caused by applied loads, dimensional error of the shaft and housing, and mounting errors, the inner and outer rings are slightly misaligned. The permissible misalignment varies depending on the NSK bearing type and operating conditions, but usually it is a small angle less than 0.0012 radian (4').

When a large misalignment is expected, bearings having a self-aligning capability, such as self-aligning ball bearings, NSK spherical roller bearings, and certain bearing units should be selected.

Rigidity and NSK Bearing Types

When loads are imposed on a NSK rolling bearing, some elastic deformation occurs in the contact areas between the rolling elements and raceways. The rigidity of the bearing is determined by the ratio of bearing load to the amount of elastic deformation of the inner and outer rings and rolling elements. For the main spindles of machine tools, it is necessary to have high rigidity of the bearings together with the rest of the spindle. Consequently, since roller bearings are deformed less by load, they are more often selected than ball bearings. When extra high rigidity is required, bearings are given a preload, which means that they have a negative clearance. Angular contract ball bearings and NSK tapered roller bearings are often preloaded.

Noise and Torque of Various NSK Bearing Types

Since rolling bearings are manufactured with very high precision, noise and torque are minimal. For NSK deep groove ball bearings and cylindrical roller bearings particularly, the noise level is sometimes specified depending on their purpose. For high precision NSK miniature ball bearings, the starting torque is specified. Deep groove ball bearings are recommended for applications in which low noise and torque are required, such as motors and instruments.

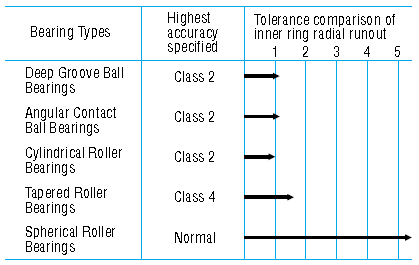

Running Accuracy and NSK Bearing Types

For the main spindles of machine tools that require high running accuracy or high speed applications like superchargers, high precision bearings of Class 5, 4 or 2 are usually used.

The running accuracy of rolling bearings is specified in various ways, and the specified accuracy classes vary depending on the bearing type. A comparison of the inner ring radial runout for the highest running accuracy specified for each bearing type is shown in Fig. below.

Relative Inner Ring Radial Runout of Highest Accuracy Class for Various NSK Bearing Types

For applications requiring high running accuracy, deep groove ball bearings, angular contact ball bearings, and cylindrical roller bearings are most suitable.

Mounting and Dismounting of Various NSK Bearing Types

Separable types of NSK bearings like cylindrical roller bearings, needle roller bearings and tapered roller bearings are convenient for mounting and dismounting. For machines in which bearings are mounted and dismounted rather often for periodic inspection, these types of bearings are recommended. Also, self-aligning ball bearings and spherical roller bearings (small ones) with tapered bores can be mounted and dismounted relatively easily using sleeves.