SKF bearing selection - SKF rolling bearings must be adequately lubricated to operate reliably. The lubricant is required to reduce friction, inhibit wear, protect the bearing surfaces against corrosion and may also be needed to provide cooling. This section describes:

how to select between grease or oil

The first step in the lubrication selection process is to decide whether to use grease or oil. In most cases, grease is the appropriate choice for open bearings.

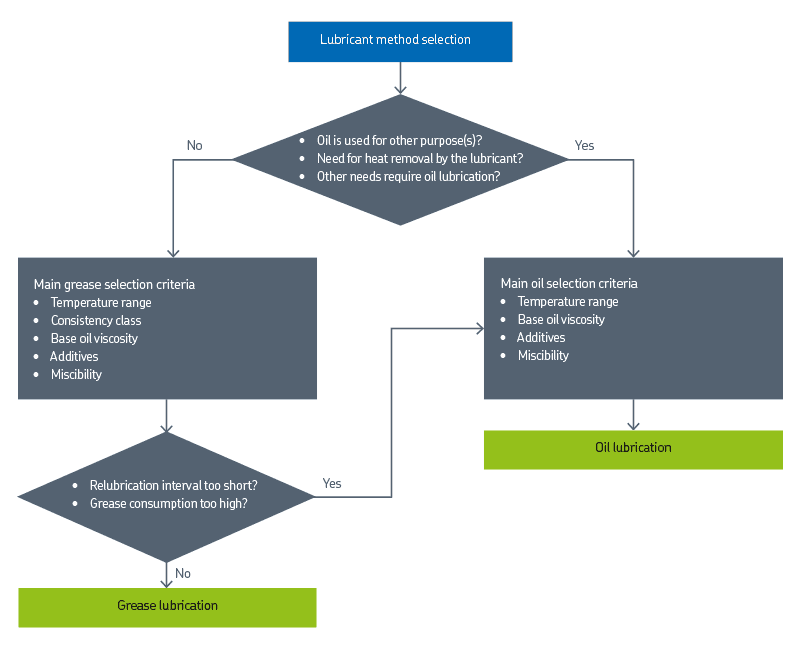

Lubrication selection flow chart and criteria

A flow chart to help select the correct lubrication method is shown as follows:

Process for selecting a suitable lubrication method for open SKF bearings

The main reasons to choose grease are:

- cost-effectiveness

- simplicity - grease is easily retained in the bearing and housing, thus requiring less complicated sealing arrangements compared with those for oil lubrication

The main exceptions to choosing grease are in applications where:

- operating conditions require a grease relubrication interval that is unacceptably short

- lubricating oil must be used for other purposes (such as in gearboxes)

- heat removal via circulating oil is required

- purging or removing used grease becomes cumbersome or expensive to handle

Estimating the relubrication interval for grease

Lubricating grease slowly degrades and therefore has a limited life. Grease life depends on the operating conditions of the bearing and the grease type. SKF rolling bearings therefore have to be relubricated if:

- the grease life is shorter than the specified bearing life

- the grease becomes contaminated

It is important to calculate the grease relubrication interval and if it is unacceptably short then, unless you use automatic (centralized) greasing, you should choose oil instead.

Relubrication should occur frequently enough to avoid grease deterioration having an adverse effect on the bearing life. Therefore, the SKF relubrication interval, tf, is defined as the time period at the end of which there is only a 1% probability that the bearing will fail because of grease degradation. This represents the L1 grease life. L10 grease life represents a 10% probability failure because of grease degradation. Grease life depends mainly on:

- bearing type and size

- speed

- load ratio C/P

- operating temperature

- grease type

As a rule, standard greases have a practical upper temperature limit of 100 °C (210 °F) on the ring with the highest temperature. Above this temperature, special greases or automatic (centralized) greasing systems should be used – otherwise, commonly the grease life would be too short.

Determining grease quantity for initial fill and relubrication

Commonly, the free volume in bearings is completely filled during installation and the free volume in SKF plummer block housings is partly filled. SKF recommends that the free volume on each side of the bearing in a customer-designed housing is equal to the free volume of the bearing. For bearings with a metallic cage, the free volume in the bearing is approximately.

Relubrication procedures

Select a relubrication procedure that suits the application and the relubrication interval tf. SKF recommends one of the following procedures:

Manual relubrication by replenishment is a convenient procedure. It enables uninterrupted operation and provides, when compared with continuous relubrication, a lower steady-state temperature.

Automatic (centralized) relubrication avoids performance issues related to over- or under-greasing. This is also commonly used where there are multiple points to lubricate, or where access to positions is difficult, or where equipment is operated remotely with no local maintenance staff .

Continuous lubrication is used when the estimated relubrication intervals are short because of the adverse effects of very severe contamination. Continuous lubrication of applications is recommended typically with ndm values < 150 000 for ball bearings and < 75 000 for roller bearings. In these cases, the initial grease fill for the housing can be from 70% to 100 % (depending on the operation condition and housing seal), and the quantity for relubrication per unit of time is derived from the equations for Gp

How to select a suitable grease

Selecting a suitable SKF grease

The assortment of SKF greases for rolling bearings provides adequate choice for most application requirements. These greases have been developed based on the latest knowledge of rolling bearing lubrication and their quality is continuously monitored.

Using LubeSelect and selection rules

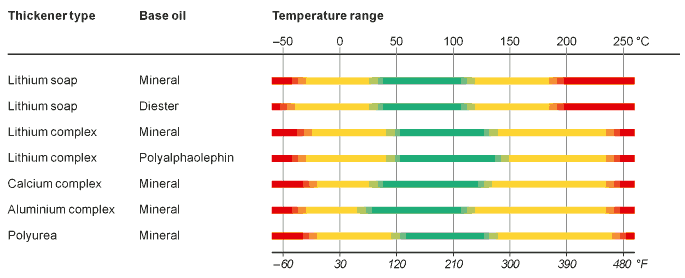

The SKF traffic light concept for grease temperature performance

Additional factors and considerations when selecting a grease

Assessing the suitability of non-SKF greases

Greases from suppliers other than SKF must be approved by the supplier.

Use The SKF traffic light concept to evaluate the temperature performance and grease life prediction. Where relevant, take into account the considerations specified for SKF greases.

Lubrication systems

Continuous lubrication can be achieved via singlepoint or multipoint automatic lubricators, e.g. SKF’s SYSTEM 24 or SYSTEM MultiPoint.

How to select a suitable oil

Oil selection criteria

When you select a lubricating oil, the most important parameters are the viscosity and viscosity index, the temperature stability (which influences the choice of oil type) and the additive package (EP/AW and corrosion protection) that fits the operating conditions for the application.

- Viscosity and viscosity index

- Oil type

- Additives

Oil change interval

The oil change interval depends upon the operating conditions and the oil type. With oil-bath lubrication, it is generally sufficient to change the oil once a year, provided the operating temperature does not exceed 50 °C (120 °F). Typically, at higher temperatures or with heavy contamination, the oil must be changed more often.

With oil circulation, the interval after which the oil needs to be changed is determined by an inspection of the oil quality, taking into account oxidation and the presence of water and abrasive particles. Oil life in circulation systems can be extended by removing particles and water from the oil.

Overview of main oil lubrication methods

The oil lubrication methods are:

- oil bath without circulating oil

- oil bath with self-circulating oil through bearing pumping action

- circulating oil with external pump

- oil jet method

- oil air method

The choice of the oil lubrication method depends mainly on:

- the bearing speed

- the need to remove heat

- the need to remove contaminants (solid particles or liquid)