SKF bearing fits can be selected by following the recommendations for bearing seat diameter tolerances. These recommendations will provide adequate solutions for the majority of applications. For more information, refer to SKF bearing selection.

SKF bearing fit to shafts and housings

The following SKF bearing fit chart provide recommendations for tolerances of shaft and housing seats. They are valid for standard applications but do not cover all details of a specific application. You should considered selecting fits and tolerances for SKF bearing seats and abutments.

These recommendations are valid for bearings with Normal dimensional tolerances. They can also be used for bearings to P6 dimensional tolerances. The tighter P6 tolerance zone changes the resulting fit only slightly. For information about tolerance, refer to SKF bearing tolerances.

Recommended seat tolerances for SKF metric bearings

For solid steel shafts

Tolerances for solid steel shafts - seats for radial ball bearings

| Conditions |

Shaft diameter mm |

Dimensional tolerance | Total radial run-out tolerance | Total axial run-out tolerance |

Ra µm |

|---|---|---|---|---|---|

| Rotating inner ring load or direction of load indeterminate | |||||

| Light loads (P ≤ 0,05 C) | ≤ 17 | js5 | IT4/2 | IT4 | 0,4 |

| > 17 to 100 | j6 | IT5/2 | IT5 | 0,8 | |

| > 100 to 140 | k6 | IT5/2 | IT5 | 1,6 | |

| Normal to heavy loads (0,05 C < P ≤ 0,1 C) | ≤ 10 | js5 | IT4/2 | IT4 | 0,4 |

| > 10 to 17 | j5 | IT4/2 | IT4 | 0,4 | |

| > 17 to 100 | k5 | IT4/2 | IT4 | 0,8 | |

| > 100 to 140 | m5 | IT4/2 | IT4 | 0,8 | |

| > 140 to 200 | m6 | IT5/2 | IT5 | 1,6 | |

| > 200 to 500 | n6 | IT5/2 | IT5 | 1,6 | |

| > 500 | p7 | IT6/2 | IT6 | 3,2 | |

| Stationary inner ring load | |||||

| Easy axial displacement of inner ring on shaft desirable | g64) | IT5/2 | IT5 | 1,6 | |

| Easy axial displacement of inner ring on shaft unnecessary | h6 | IT5/2 | IT5 | 1,6 | |

| Axial loads only | j6 | IT5/2 | IT5 | 1,6 | |

Tolerances for solid steel shafts - seats for radial roller bearings

| Conditions |

Shaft diameter mm |

Dimensional tolerance | Total radial run-out tolerance | Total axial run-out tolerance |

Ra µm |

|---|---|---|---|---|---|

| Rotating inner ring load or direction of load indeterminate | |||||

| Light loads (P ≤ 0,05 C) | ≤ 25 | j6 | IT5/2 | IT5 | 0,8 |

| > 25 to 60 | k6 | IT5/2 | IT5 | 0,8 | |

| > 60 to 140 | m6 | IT5/2 | IT5 | 0,8 | |

| Normal to heavy loads (0,05 C < P ≤ 0,1 C) | ≤ 30 | k6 | IT5/2 | IT5 | 0,8 |

| > 30 to 50 | m5 | IT5/2 | IT5 | 0,8 | |

| > 50 to 65 | n5 | IT5/2 | IT5 | 0,8 | |

| > 65 to 100 | n6 | IT5/2 | IT5 | 0,8 | |

| > 100 to 280 | p6 | IT5/2 | IT5 | 1,6 | |

| > 280 to 500 | r6 | IT5/2 | IT5 | 1,6 | |

| > 500 | r7 | IT6/2 | IT6 | 3,2 | |

|

Heavy to very heavy loads and high peak loads under difficult operating conditions (P > 0,1 C) |

> 50 to 65 | n5 | IT5/2 | IT5 | 0,8 |

| > 65 to 85 | n6 | IT5/2 | IT5 | 0,8 | |

| > 85 to 140 | p6 | IT5/2 | IT5 | 0,8 | |

| > 140 to 300 | r6 | IT5/2 | IT5 | 1,6 | |

| > 300 to 500 | r6 + IT64) | IT5/2 | IT5 | 1,6 | |

| > 500 | r7 + IT74) | IT6/2 | IT6 | 3,2 | |

| Stationary inner ring load | |||||

| Easy axial displacement of inner ring on shaft desirable | g65) | IT5/2 | IT5 | 1,6 | |

| Easy axial displacement of inner ring on shaft unnecessary | h6 | IT5/2 | IT5 | 1,6 | |

| Axial loads only | j6 | IT5/2 | IT5 | 1,6 | |

Tolerances for solid steel shafts - seats for thrust bearings

| Conditions |

Shaft diameter mm |

Dimensional tolerance | Total radial run-out tolerance | Total axial run-out tolerance |

Ra µm |

|---|---|---|---|---|---|

| Axial loads only on thrust ball bearings | |||||

| h6 | IT5/2 | IT5 | 1,6 | ||

| Combined radial and axial loads on spherical roller thrust bearings | |||||

| Stationary load on shaft washer | all | j6 | IT5/2 | IT5 | 1,6 |

| Rotating load on shaft washer, | ≤ 200 | k6 | IT5/2 | IT5 | 1,6 |

| or direction of load indeterminate | > 200 to 400 | m6 | IT5/2 | IT5 | 1,6 |

| > 400 | n6 | IT5/2 | IT5 | 1,6 | |

For cast iron and steel housings

Tolerances for cast iron and steel housings – seats for radial bearings

| Conditions | Dimensional tolerance | Total radial run-out tolerance | Total axial run-out tolerance | Ra | Displacement of outer ring | |

|---|---|---|---|---|---|---|

| For non-split housings only | Rotating outer ring load | |||||

| Heavy loads on bearings in thin-walled housings, heavy peak loads (P > 0,1 C) | P7 | IT6/2 | IT6 | 3,2 | Cannot be displaced | |

| Normal to heavy loads (P > 0,05 C) | N7 | IT6/2 | IT6 | 3,2 | Cannot be displaced | |

| Light and variable loads (P = 0,05 C) | M7 | IT6/2 | IT6 | 3,2 | Cannot be displaced | |

| Direction of load indeterminate | ||||||

| Heavy peak loads | M7 | IT6/2 | IT6 | 3,2 | Cannot be displaced | |

| Normal to heavy loads (P > 0,05 C), axial displacement of outer ring unnecessary | K75) | IT6/2 | IT6 | 3,2 | In most cases, cannot be displaced | |

| For non-split housings and split housings | Direction of load indeterminate | |||||

| Light to normal loads (P = 0,1 C), axial displacement of outer ring desirable | J7 | IT6/2 | IT6 | 3,2 | In most cases, can be displaced | |

| Stationary outer ring load | ||||||

| Loads of all kinds | H73) | IT6/2 | IT6 | 3,2 | Can be displaced | |

| Light to normal loads (P = 0,1 C) with simple working conditions | H83) | IT6/2 | IT6 | 3,2 | Can be displaced | |

| Thermal expansion of the shaft | G74) | IT6/2 | IT6 | 3,2 | Can be displaced | |

Tolerances for cast iron and steel housings - seats for thrust bearings

| Conditions | Dimensional tolerance | Total axial run-out tolerance | Ra | Remarks |

|---|---|---|---|---|

| Axial loads only | ||||

| Thrust ball bearings | H8 | IT7 | 6,3 |

For less precise bearing arrangements, there can be a radial clearance of up to 0,001 D. |

|

Spherical roller thrust bearings where separate bearings provide radial location |

– | IT6 |

Housing washer must be fitted with an adequate radial gap so that no radial load can act on the thrust bearings. |

|

| Combined radial and axial loads on spherical roller thrust bearings | ||||

|

Stationary load on housing washer arrangements |

H7 | IT6 | 3,2 | |

| Rotating load on housing washer | M7 | IT6 | 3,2 | |

SKF bearings with a tapered bore mounted on tapered sleeves

SKF bearings with a tapered bore are always mounted with an interference fit for the inner ring. The fit is determined by the distance through which the inner ring is driven up on a tapered sleeve.

For seats of bearings mounted on tapered sleeves, wider diameter tolerances are permissible. The total run-out tolerances should be the same as for bearings on cylindrical seats.

Suitable tolerances are listed in table below. They are valid for moderate speeds and moderate precision requirements.

Tolerances for seats of bearings mounted on tapered sleeves

|

Shaft diameter d Nominal |

Diameter tolerance h9 |

Total radial run-out IT5/2 |

||

|---|---|---|---|---|

| > | ≤ | U | L | max. |

| mm | μm | μm | ||

| 10 | 18 | 0 | –43 | 4 |

| 18 | 30 | 0 | –52 | 5 |

| 30 | 50 | 0 | –62 | 6 |

| 50 | 80 | 0 | –74 | 7 |

| 80 | 120 | 0 | –87 | 8 |

| 120 | 180 | 0 | –100 | 9 |

| 180 | 250 | 0 | –115 | 10 |

| 250 | 315 | 0 | –130 | 12 |

| 315 | 400 | 0 | –140 | 13 |

| 400 | 500 | 0 | –155 | 14 |

| 500 | 630 | 0 | –175 | 16 |

| 630 | 800 | 0 | –200 | 18 |

| 800 | 1 000 | 0 | –230 | 20 |

| 1 000 | 1 250 | 0 | –260 | 24 |

SKF bearing fit chart do not cover all details of a specific application and so you may find that adjustments may be necessary. When selecting fits, you should consider the following topics.

SKF bearing fits selection

Conditions of rotation

Conditions of rotation refer to the relative motion between a bearing ring and the load acting upon it. Essentially, there are three different conditions:

- rotating load

- stationary load

- direction of load indeterminate

Conditions of rotation

| Operating conditions | Schematic illustration | Load condition | Recommended fits |

|---|---|---|---|

| Rotating inner ring |

|

Rotating inner ring load | Interference fit for the inner ring |

| Stationary outer ring | Stationary outer ring load | Loose fit for the outer ring possible | |

| Constant load direction | |||

| Rotating inner ring |

|

Stationary inner ring load | Loose fit for the inner ring possible |

| Stationary outer ring | Rotating outer ring load | Interference fit for the outer ring | |

| Load rotates with the inner ring | |||

| Stationary inner ring |

|

Stationary inner ring load | Loose fit for the inner ring possible |

| Rotating outer ring | Rotating outer ring load | Interference fit for the outer ring | |

| Constant load direction | |||

| Stationary inner ring |

|

Rotating inner ring load |

Interference fit for the inner ring |

| Rotating outer ring | Stationary outer ring load | Loose fit for the outer ring possible | |

| Load rotates with outer ring |

Rotating loads occur where either the bearing ring or the applied load is stationary while the other rotates. A bearing ring mounted with a loose fit will creep on its seat when subjected to a rotating load, and this can lead to fretting corrosion and eventually wear. To prevent this from happening, an adequate interference fit, between the ring subjected to rotating load and its seat, is required. For the purpose of selecting fits, loads that oscillate (such as loads acting on connecting rod bearings) are considered to be rotating loads.

Stationary loads occur where both the bearing ring and the applied load are stationary or both are rotating at the same speed. Under these conditions, a bearing ring normally does not creep and there is no risk of fretting corrosion or wear. In this case, the ring does not need to have an interference fit.

Direction of load indeterminate refers to variable or alternating external loads, sudden load peaks, vibration or unbalanced loads in high-speed applications. These give rise to changes in the direction of load, which cannot be accurately described. Where the direction of load is indeterminate and particularly where heavy loads are involved, there is a risk of fretting corrosion or wear. You should use an interference fit for both rings. The same fit as for a rotating load is normally suitable.

Where the outer ring should be able to move axially in its housing, a loose fit must be used. However, a loose fit can result in housing wear. Where this cannot be tolerated, either protect the bearing seat surface or select a bearing that accommodates the axial displacement within itself (cylindrical roller, needle roller or CARB bearing). These bearings can be mounted with an interference fit for both rings.

Magnitude of load

The ring of a SKF bearing deforms proportionately to the load. For rotating inner ring loads, this deformation can loosen the interference fit between the inner ring and shaft, causing the ring to creep on its shaft seat. The heavier the load, the tighter the interference fit required. The required interference can be estimated using:

| Δ | required interference [µm] |

| d | bearing bore diameter [mm] |

| B | bearing width [mm] |

| Fr | radial load [kN] |

Where sudden load peaks or vibration occurs, a tighter fit can be required.

Temperature differences

- In operation, bearing rings normally reach a temperature that is higher than that of the components to which they are fitted. This can loosen the fit on the shaft seat, while outer ring expansion can prevent the desired axial displacement in the housing.

- Rapid start-up can loosen the inner ring fit when the frictional heat generated by the bearing is not dissipated quickly enough. In some cases, friction from seals can generate enough heat to loosen the inner ring fit.

- External heat and the direction of heat flow can have an effect on fits. Steady-state and transient conditions must be considered.

Precision requirements

To minimize deflections and vibration in precision or high-speed applications, interference or transition fits are recommended.

Design and material of the shaft and housing

- Distortion of the bearing rings caused by shaft or housing design, for example by discontinuities of the seat or uneven wall thickness, should be avoided.

- For split housings, SKF generally recommends loose fits. The tighter (less loose) the fit is in a split housing, the higher are the requirements for the geometrical tolerances of the seat. Split housings machined to tight tolerances, such as SKF plummer block housings, can be used for transition fits up to K7.

- Bearings mounted in thin-walled housings or on hollow shafts require tighter interference fits than those recommended for robust cast iron housings or solid shafts.

- Shafts or housings made of materials other than steel or cast iron may require different fits depending on material strength and thermal properties.

Ease of mounting and dismounting

Loose fits are beneficial for easy mounting and dismounting. In applications where interference fits are required for both the shaft and housing seat, separable bearings or bearings with a tapered bore should be considered. Bearings with a tapered bore can be mounted on tapered sleeves or on a tapered shaft seat.

Axial displacement of the bearing in the non-locating position

Where a non-locating bearing needs to be able to move axially on its seat, the ring subjected to the stationary load should have a loose fit. For additional information about SKF bearings in the non-locating position, refer to SKF bearing type and arrangement.

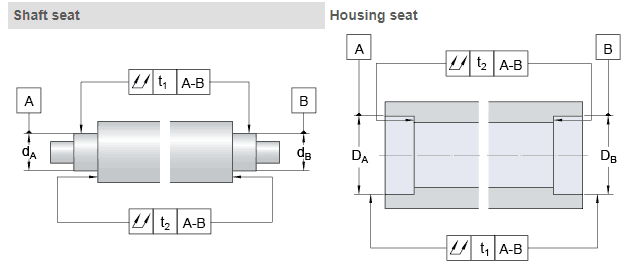

Tolerances for SKF bearing seats and abutments

Dimensional tolerances for bearing seats are dictated by the required fit. Precision requirements of the application will direct you to which bearing tolerance class to use , and consequently, what run-out tolerance of the seat is needed. The run-out of the seat is specified by the total radial run-out of the seat surface and the total axial run-out of the abutment (ISO 1101, 18.16).

For bearings with Normal tolerances in general industrial applications, seats are typically machined to the following tolerances:

- shaft seats to grade IT6 dimensional tolerances and grade IT5 total run-out tolerances

- housing seats to grade IT7 dimensional tolerances and grade IT6 total run-out tolerances

Suitable combinations of tolerance grades are listed in table below.

| Dimensional tolerance grade | Geometrical tolerance grades | Dimensional tolerance grade | Geometrical tolerance grades | |||

|---|---|---|---|---|---|---|

| Radial run-out | Axial run-out | Radial run-out | Axial run-out | |||

| t1 | t2 | t1 | t2 | |||

|

Bearing to Normal tolerances (moderate speed and running accuracy) |

IT6 | IT5/2 | IT5 | IT7 | IT6/2 | IT6 |

|

Bearing to P6 tolerances (higher speeds or running accuracy) |

IT5 | IT4/2 | IT4 | IT6 | IT5/2 | IT5 |

|

Bearing to P5 tolerances (high speeds and running accuracy) |

IT4 | IT3/2 | IT3 | IT5 | IT4/2 | IT4 |

The tolerance zone for the total radial run-out is limited to half of the ISO tolerance grade, because the run-out tolerance is specified as a difference in radii of two coaxial cylinders, and the ISO tolerance grade refers to the diameter.

For seats of bearings mounted on withdrawal or adapter sleeves, wider diameter tolerances are permissible. The total run-out tolerances should be the same as for bearings on cylindrical seats.

Tolerance values for ISO tolerance grades are listed in table below.

| Nominal | Tolerance grades | |||||||

| dimension | IT3 | IT4 | IT5 | IT6 | IT7 | IT8 | IT9 | |

| > | ≤ | max. | ||||||

| mm | µm | |||||||

| 1 | 3 | 2 | 3 | 4 | 6 | 10 | 14 | 25 |

| 3 | 6 | 3 | 4 | 5 | 8 | 12 | 18 | 30 |

| 6 | 10 | 3 | 4 | 6 | 9 | 15 | 22 | 36 |

| 10 | 18 | 3 | 5 | 8 | 11 | 18 | 27 | 43 |

| 18 | 30 | 4 | 6 | 9 | 13 | 21 | 33 | 52 |

| 30 | 50 | 4 | 7 | 11 | 16 | 25 | 39 | 62 |

| 50 | 80 | 5 | 8 | 13 | 19 | 30 | 46 | 74 |

| 80 | 120 | 6 | 10 | 15 | 22 | 35 | 54 | 87 |

| 120 | 180 | 8 | 12 | 18 | 25 | 40 | 63 | 100 |

| 180 | 250 | 10 | 14 | 20 | 29 | 46 | 72 | 115 |

| 250 | 315 | 12 | 16 | 23 | 32 | 52 | 81 | 130 |

| 315 | 400 | 13 | 18 | 25 | 36 | 57 | 89 | 140 |

| 400 | 500 | 15 | 20 | 27 | 40 | 63 | 97 | 155 |

| 500 | 630 | – | – | 32 | 44 | 70 | 110 | 175 |

| 630 | 800 | – | – | 36 | 50 | 80 | 125 | 200 |

| 800 | 1 000 | – | – | 40 | 56 | 90 | 140 | 230 |

| 1 000 | 1 250 | – | – | 47 | 66 | 105 | 165 | 260 |

| 1 250 | 1 600 | – | – | 55 | 78 | 125 | 195 | 310 |

| 1 600 | 2 000 | – | – | 65 | 92 | 150 | 230 | 370 |

| 2 000 | 2 500 | – | – | 78 | 110 | 175 | 280 | 440 |

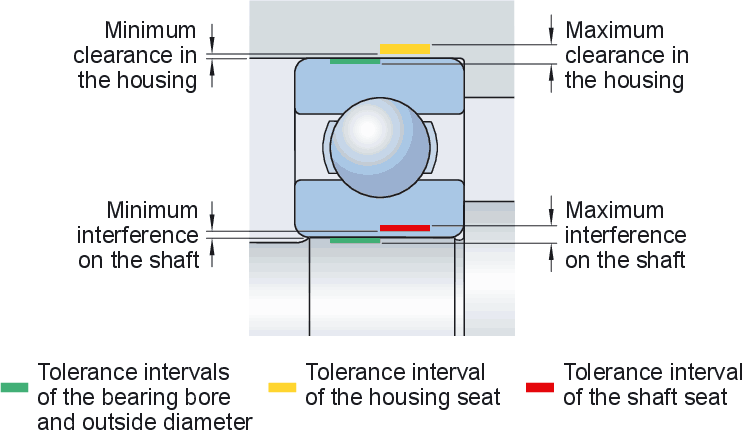

Tolerances and resultant fits chart

Shaft and housing tolerances and resultant fits

The tables in this section provide information about bearing tolerances, seat tolerances and resultant fits. These should enable you to determine easily the maximum and minimum values of fits when using ISO tolerance classes for bearing seats and bearings with Normal tolerances for the bore and outside diameter.

The tables cannot be used for SKF tapered roller bearings when d ≤ 30 mm or D ≤ 150 mm, or for thrust bearings when D ≤ 150 mm. The diameter tolerances for these bearings deviate from the Normal tolerances for other rolling bearings.

The tables list:

- the upper and lower limits of bore or outside diameter deviations for bearings with Normal tolerances

- the upper and lower limits of shaft or housing bore diameter deviations for relevant tolerance classes in accordance with ISO 2862

- the smallest and largest values of the theoretical interference (–) or clearance (+)

- the smallest and largest values of the ±3σ probable interference (–) or clearance (+)

The appropriate values for shaft seats are listed for the following tolerance classes:

Shaft tolerances and resultant fits

|

Shaft Nominal diameter |

Bearing Bore diameter tolerance |

Shaft diameter deviations, resultant fits Tolerance classes |

|||||||||||

| d | tΔdmp | f5 | f6 | g5 | g6 | h5 | |||||||

| Deviations (shaft diameter) | |||||||||||||

| Theoretical interference (–)/clearance (+) | |||||||||||||

| over | incl. | low | high | Probable interference (–)/clearance (+) | |||||||||

| mm | µm | µm | |||||||||||

| – | 3 | –8 | 0 | –6 | –10 | –6 | –12 | –2 | –6 | –2 | –8 | 0 | –4 |

| –2 | +10 | –2 | +12 | –6 | +6 | –6 | +8 | –8 | +4 | ||||

| –1 | +9 | 0 | +10 | –5 | +5 | –4 | +6 | –7 | +3 | ||||

| 3 | 6 | –8 | 0 | –10 | –15 | –10 | –18 | –4 | –9 | –4 | –12 | 0 | –5 |

| +2 | +15 | +2 | +18 | –4 | +9 | –4 | +12 | –8 | +5 | ||||

| +3 | +14 | +4 | +16 | –3 | +8 | –2 | +10 | –7 | +4 | ||||

| 6 | 10 | –8 | 0 | –13 | –19 | –13 | –22 | –5 | –11 | –5 | –14 | 0 | –6 |

| +5 | +19 | +5 | +22 | –3 | +11 | –3 | +14 | –8 | +6 | ||||

| +7 | +17 | +7 | +20 | –1 | +9 | –1 | +12 | –6 | +4 | ||||

| 10 | 18 | –8 | 0 | –16 | –24 | –16 | –27 | –6 | –14 | –6 | –17 | 0 | –8 |

| +8 | +24 | +8 | +27 | –2 | +14 | –2 | +17 | –8 | +8 | ||||

| +10 | +22 | +10 | +25 | 0 | +12 | 0 | +15 | –6 | +6 | ||||

| 18 | 30 | –10 | 0 | –20 | –29 | –20 | –33 | –7 | –16 | –7 | –20 | 0 | –9 |

| +10 | +29 | +10 | +33 | –3 | +16 | –3 | +20 | –10 | +9 | ||||

| +12 | +27 | +13 | +30 | –1 | +14 | 0 | +17 | –8 | +7 | ||||

| 30 | 50 | –12 | 0 | –25 | –36 | –25 | –41 | –9 | –20 | –9 | –25 | 0 | –11 |

| +13 | +36 | +13 | +41 | –3 | +20 | –3 | +25 | –12 | +11 | ||||

| +16 | +33 | +17 | +37 | 0 | +17 | +1 | +21 | –9 | +8 | ||||

| 50 | 80 | –15 | 0 | –30 | –43 | –30 | –49 | –10 | –23 | –10 | –29 | 0 | –13 |

| +15 | +43 | +15 | +49 | –5 | +23 | –5 | +29 | –15 | +13 | ||||

| +19 | +39 | +19 | +45 | –1 | +19 | –1 | +25 | –11 | +9 | ||||

| 80 | 120 | –20 | 0 | –36 | –51 | –36 | –58 | –12 | –27 | –12 | –34 | 0 | –15 |

| +16 | +51 | +16 | +58 | –8 | +27 | –8 | +34 | –20 | +15 | ||||

| +21 | +46 | +22 | +52 | –3 | +22 | –2 | +28 | –15 | +10 | ||||

| 120 | 180 | –25 | 0 | –43 | –61 | –43 | –68 | –14 | –32 | –14 | –39 | 0 | –18 |

| +18 | +61 | +18 | +68 | –11 | +32 | –11 | +39 | –25 | +18 | ||||

| +24 | +55 | +25 | +61 | –5 | +26 | –4 | +32 | –19 | +12 | ||||

| 180 | 250 | –30 | 0 | –50 | –70 | –50 | –79 | –15 | –35 | –15 | –44 | 0 | –20 |

| +20 | +70 | +20 | +79 | –15 | +35 | –15 | +44 | –30 | +20 | ||||

| +26 | +64 | +28 | +71 | –9 | +29 | –7 | +36 | –24 | +14 | ||||

| 250 | 315 | –35 | 0 | –56 | –79 | –56 | –88 | –17 | –40 | –17 | –49 | 0 | –23 |

| +21 | +79 | +21 | +88 | –18 | +40 | –18 | +49 | –35 | +23 | ||||

| +29 | +71 | +30 | +79 | –10 | +32 | –9 | +40 | –27 | +15 | ||||

| 315 | 400 | –40 | 0 | –62 | –87 | –62 | –98 | –18 | –43 | –18 | –54 | 0 | –25 |

| +22 | +87 | +22 | +98 | –22 | +43 | –22 | +54 | –40 | +25 | ||||

| +30 | +79 | +33 | +87 | –14 | +35 | –11 | +43 | –32 | +17 | ||||

| 400 | 500 | –45 | 0 | –68 | –95 | –68 | –108 | –20 | –47 | –20 | –60 | 0 | –27 |

| +23 | +95 | +23 | +108 | –25 | +47 | –25 | +60 | –45 | +27 | ||||

| +32 | +86 | +35 | +96 | –16 | +38 | –13 | +48 | –36 | +18 | ||||

| 500 | 630 | –50 | 0 | –76 | –104 | –76 | –120 | –22 | –50 | –22 | –66 | 0 | –28 |

| +26 | +104 | +26 | +120 | –28 | +50 | –28 | +66 | –50 | +28 | ||||

| +36 | +94 | +39 | +107 | –18 | +40 | –15 | +53 | –40 | +18 | ||||

| 630 | 800 | –75 | 0 | –80 | –112 | –80 | –130 | –24 | –56 | –24 | –74 | 0 | –32 |

| +5 | +112 | +5 | +130 | –51 | +56 | –51 | +74 | –75 | +32 | ||||

| +17 | +100 | +22 | +113 | –39 | +44 | –34 | +57 | –63 | +20 | ||||

| 800 | 1 000 | –100 | 0 | –86 | –122 | –86 | –142 | –26 | –62 | –26 | –82 | 0 | –36 |

| –14 | +122 | –14 | +142 | –74 | +62 | –74 | +82 | –100 | +36 | ||||

| 0 | +108 | +6 | +122 | –60 | +48 | –54 | +62 | –86 | +22 | ||||

| 1 000 | 1 250 | –125 | 0 | –98 | –140 | –98 | –164 | –28 | –70 | –28 | –94 | 0 | –42 |

| –27 | +140 | –27 | +164 | –97 | +70 | –97 | +94 | –125 | +42 | ||||

| –10 | +123 | –3 | +140 | –80 | +53 | –73 | +70 | –108 | +25 | ||||

| 1 250 | 1 600 | –160 | 0 | –110 | –160 | –110 | –188 | –30 | –80 | –30 | –108 | 0 | –50 |

| –50 | +160 | –50 | +188 | –130 | +80 | –130 | +108 | –160 | +50 | ||||

| –29 | +139 | –20 | +158 | –109 | +59 | –100 | +78 | –139 | +29 | ||||

| 1 600 | 2 000 | –200 | 0 | –120 | –180 | –120 | –212 | –32 | –92 | –32 | –124 | 0 | –60 |

| –80 | +180 | –80 | +212 | –168 | +92 | –168 | +124 | –200 | +60 | ||||

| –55 | +155 | –45 | +177 | –143 | +67 | –133 | +89 | –175 | +35 | ||||

|

Shaft Nominal diameter |

Bearing Bore diameter tolerance |

Shaft diameter deviations, resultant fits Tolerance classes |

|||||||||||

| d | tΔdmp | h6 | h8 | h9 | j5 | j6 | |||||||

| Deviations (shaft diameter) | |||||||||||||

| Theoretical interference (–)/clearance (+) | |||||||||||||

| > | ≤ | L | U | Probable interference (–)/clearance (+) | |||||||||

| mm | µm | µm | |||||||||||

| – | 3 | –8 | 0 | 0 | –6 | 0 | –14 | 0 | –25 | +2 | –2 | +4 | –2 |

| –8 | +6 | –8 | +14 | –8 | +25 | –10 | +2 | –12 | +2 | ||||

| –6 | +4 | –6 | +12 | –5 | +22 | –9 | +1 | –10 | 0 | ||||

| 3 | 6 | –8 | 0 | 0 | –8 | 0 | –18 | 0 | –30 | +3 | –2 | +6 | –2 |

| –8 | +8 | –8 | +18 | –8 | +30 | –11 | +2 | –14 | +2 | ||||

| –6 | +6 | –5 | +15 | –5 | +27 | –10 | +1 | –12 | 0 | ||||

| 6 | 10 | –8 | 0 | 0 | –9 | 0 | –22 | 0 | –36 | +4 | –2 | +7 | –2 |

| –8 | +9 | –8 | +22 | –8 | +36 | –12 | +2 | –15 | +2 | ||||

| –6 | +7 | –5 | +19 | –5 | +33 | –10 | 0 | –13 | 0 | ||||

| 10 | 18 | –8 | 0 | 0 | –11 | 0 | –27 | 0 | –43 | +5 | –3 | +8 | –3 |

|

Shaft Nominal diameter |

Bearing Bore diameter tolerance |

Shaft diameter deviations, resultant fits Tolerance classes |

|||||||||||

| d | tΔdmp | js4 | js5 | js6 | js7 | k4 | |||||||

| Deviations (shaft diameter) | |||||||||||||

| Theoretical interference (–)/clearance (+) | |||||||||||||

| over | incl. | low | high | Probable interference (–)/clearance (+) | |||||||||

| mm | µm | µm | |||||||||||

| – | 3 | –8 | 0 | +1,5 | –1,5 | +2 | –2 | +3 | –3 | +5 | –5 | +3 | 0 |

| –9,5 | +1,5 | –10 | +2 | –11 | +3 | –13 | +5 | –11 | 0 | ||||

| –8,5 | +0,5 | –9 | +1 | –9 | +1 | –11 | +3 | –10 | –1 | ||||

| 3 | 6 | –8 | 0 | +2 | –2 | +2,5 | –2,5 | +4 | –4 | +6 | –6 | +5 | +1 |

| –10 | +2 | –10,5 | +2,5 | –12 | +4 | –14 | +6 | –13 | –1 | ||||

| –9 | +1 | –9 | +1 | –10 | +2 | –12 | +4 | –12 | –2 | ||||

| 6 | 10 | –8 | 0 | +2 | –2 | +3 | –3 | +4,5 | –4,5 | +7,5 | –7,5 | +5 | +1 |

| –10 | +2 | –11 | +3 | –12,5 | +4,5 | –15,5 | +7,5 | –13 | –1 | ||||

| –9 | +1 | –9 | +1 | –11 | +3 | –13 | +5 | –12 | –2 | ||||

| 10 | 18 | –8 | 0 | +2,5 | –2,5 | +4 | –4 | +5,5 | –5,5 | +9 | –9 | +6 | +1 |

| –10,5 | +2,5 | –12 | +4 | –13,5 | +5,5 | –17 | +9 | –14 | –1 | ||||

| –9,5 | +1,5 | –10 | +2 | –11 | +3 | –14 | +6 | –13 | –2 | ||||

| 18 | 30 | –10 | 0 | +3 | –3 | +4,5 | –4,5 | +6,5 | –6,5 | +10,5 | –10,5 | +8 | +2 |

| –13 | +3 | –14,5 | +4,5 | –16,5 | +6,5 | –20,5 | +10,5 | –18 | –2 | ||||

| –10,5 | +1,5 | –12 | +2 | –14 | +4 | –17 | +7 | –16 | –4 | ||||

| 30 | 50 | –12 | 0 | +3,5 | –3,5 | +5,5 | –5,5 | +8 | –8 | +12,5 | –12,5 | +9 | +2 |

| –15,5 | +3,5 | –17,5 | +5,5 | –20 | +8 | –24,5 | +12,5 | –21 | –2 | ||||

| –13,5 | +1,5 | –15 | +3 | –16 | +4 | –20 | +8 | –19 | –4 | ||||

| 50 | 80 | –15 | 0 | +4 | –4 | +6,5 | –6,5 | +9,5 | –9,5 | +15 | –15 | +10 | +2 |

| –19 | +4 | –21,5 | +6,5 | –24,5 | +9,5 | –30 | +15 | –25 | –2 | ||||

| –15,5 | +1,5 | –18 | +3 | –20 | +5 | –25 | +10 | –22 | –5 | ||||

| 80 | 120 | –20 | 0 | +5 | –5 | +7,5 | –7,5 | +11 | –11 | +17,5 | –17,5 | +13 | +3 |

| –25 | +5 | –27,5 | +7,5 | –31 | +11 | –37,5 | +17,5 | –33 | –3 | ||||

| –22 | +2 | –23 | +3 | –25 | +5 | –31 | +11 | –30 | –6 | ||||

| 120 | 180 | –25 | 0 | +6 | –6 | +9 | –9 | +12,5 | –12,5 | +20 | –20 | +15 | +3 |

| –31 | +6 | –34 | +9 | –37,5 | +12,5 | –45 | +20 | –40 | –3 | ||||

| –27 | +2 | –28 | +3 | –31 | +6 | –37 | +12 | –36 | –7 | ||||

| 180 | 250 | –30 | 0 | +7 | –7 | +10 | –10 | +14,5 | –14,5 | +23 | –23 | +18 | +4 |

| –37 | +7 | –40 | +10 | –44,5 | +14,5 | –53 | +23 | –48 | –4 | ||||

| –32 | +2 | –34 | +4 | –36 | +6 | –43 | +13 | –43 | –9 | ||||

| 250 | 315 | –35 | 0 | +8 | –8 | +11,5 | –11,5 | +16 | –16 | +26 | –26 | +20 | +4 |

| –4 | +8 | –46,5 | +11,5 | –51 | +16 | –61 | +26 | –55 | –4 | ||||

| –37 | +2 | –39 | +4 | –42 | +7 | –49 | +14 | –49 | –10 | ||||

| 315 | 400 | –40 | 0 | +9 | –9 | +12,5 | –12,5 | +18 | –18 | +28,5 | –28,5 | +22 | +4 |

| –49 | +9 | –52,5 | +12,5 | –58 | +18 | –68,5 | +28,5 | –62 | –4 | ||||

| –42 | +2 | –44 | +4 | –47 | +7 | –55 | +15 | –55 | –11 | ||||

| 400 | 500 | –45 | 0 | +10 | –10 | +13,5 | –13,5 | +20 | –20 | +31,5 | –31,5 | +25 | +5 |

| –55 | +10 | –58,5 | +13,5 | –65 | +20 | –76,5 | +31,5 | –70 | –5 | ||||

| –48 | +3 | –49 | +4 | –53 | +8 | –62 | +17 | –63 | –12 | ||||

| 500 | 630 | –50 | 0 | – | – | +14 | –14 | +22 | –22 | +35 | –35 | – | – |

| – | – | –64 | +14 | –72 | +22 | –85 | +35 | – | – | ||||

| – | – | –54 | +4 | –59 | +9 | –69 | +19 | – | – | ||||

| 630 | 800 | –75 | 0 | – | – | +16 | –16 | +25 | –25 | +40 | –40 | – | – |

| – | – | –91 | +16 | –100 | +25 | –115 | +40 | – | – | ||||

| – | – | –79 | +4 | –83 | +8 | –93 | +18 | – | – | ||||

| 800 | 1 000 | –100 | 0 | – | – | +18 | –18 | +28 | –28 | +45 | –45 | – | – |

| – | – | –118 | +18 | –128 | +28 | –145 | +45 | – | – | ||||

| – | – | –104 | +4 | –108 | +8 | –118 | +18 | – | – | ||||

| 1 000 | 1 250 | –125 | 0 | – | – | +21 | –21 | +33 | –33 | +52 | –52 | – | – |

| – | – | –146 | +21 | –158 | +33 | –177 | +52 | – | – | ||||

| – | – | –129 | +4 | –134 | +9 | –145 | +20 | – | – | ||||

| 1 250 | 1 600 | –160 | 0 | – | – | +25 | –25 | +39 | –39 | +62 | –62 | – | – |

| – | – | –185 | +25 | –199 | +39 | –222 | +62 | – | – | ||||

| – | – | –164 | +4 | –169 | +9 | –182 | +22 | – | – | ||||

| 1 600 | 2 000 | –200 | 0 | – | – | +30 | –30 | +46 | –46 | +75 | –75 | – | – |

| – | – | –230 | +30 | –246 | +46 | –275 | +75 | – | – | ||||

| – | – | –205 | +5 | –211 | +11 | –225 | +25 | – | – | ||||

|

Shaft Nominal diameter |

Bearing Bore diameter tolerance |

Shaft diameter deviations, resultant fits Tolerance classes |

|||||||||||

| d | tΔdmp | k5 | k6 | m5 | m6 | n5 | |||||||

| Deviations (shaft diameter) | |||||||||||||

| Theoretical interference (–) | |||||||||||||

| > | ≤ | L | U | Probable interference (–) | |||||||||

| mm | µm | µm | |||||||||||

| – | 3 | –8 | 0 | +4 | 0 | +6 | 0 | +6 | +2 | +8 | +2 | +8 | +4 |

| –12 | 0 | –14 | 0 | –14 | –2 | –16 | –2 | –16 | –4 | ||||

| –11 | –1 | –12 | –2 | –13 | –3 | –14 | –4 | –15 | –5 | ||||

| 3 | 6 | –8 | 0 | +6 | +1 | +9 | +1 | +9 | +4 | +12 | +4 | +13 | +8 |

| –14 | –1 | –17 | –1 | –17 | –4 | –20 | –4 | –21 | –8 | ||||

| –13 | –2 | –15 | –3 | –16 | –5 | –18 | –6 | –20 | –9 | ||||

| 6 | 10 | –8 | 0 | +7 | +1 | +10 | +1 | +12 | +6 | +15 | +6 | +16 | +10 |

| –15 | –1 | –18 | –1 | –20 | –6 | –23 | –6 | –24 | –10 | ||||

| –13 | –3 | –16 | –3 | –18 | –8 | –21 | –8 | –22 | –12 | ||||

| 10 | 18 | –8 | 0 | +9 | +1 | +12 | +1 | +15 | +7 | +18 | +7 | +20 | +12 |

| –17 | –1 | –20 | –1 | –23 | –7 | –26 | –7 | –28 | –12 | ||||

| –15 | –3 | –18 | –3 | –21 | –9 | –24 | –9 | –26 | –14 | ||||

| 18 | 30 | –10 | 0 | +11 | +2 | +15 | +2 | +17 | +8 | +21 | +8 | +24 | +15 |

| –21 | –2 | –25 | –2 | –27 | –8 | –31 | –8 | –34 | –15 | ||||

| –19 | –4 | –22 | –5 | –25 | –10 | –28 | –11 | –32 | –17 | ||||

| 30 | 50 | –12 | 0 | +13 | +2 | +18 | +2 | +20 | +9 | +25 | +9 | +28 | +17 |

| –25 | –2 | –30 | –2 | –32 | –9 | –37 | –9 | –40 | –17 | ||||

| –22 | –5 | –26 | –6 | –29 | –12 | –33 | –13 | –37 | –20 | ||||

| 50 | 80 | –15 | 0 | +15 | +2 | +21 | +2 | +24 | +11 | +30 | +11 | +33 | +20 |

| –30 | –2 | –36 | –2 | –39 | –11 | –45 | –11 | –48 | –20 | ||||

| –26 | –6 | –32 | –6 | –35 | –15 | –41 | –15 | –44 | –24 | ||||

| 80 | 120 | –20 | 0 | +18 | +3 | +25 | +3 | +28 | +13 | +35 | +13 | +38 | +23 |

| –38 | –3 | –45 | –3 | –48 | –13 | –55 | –13 | –58 | –23 | ||||

| –33 | –8 | –39 | –9 | –43 | –18 | –49 | –19 | –53 | –28 | ||||

| 120 | 180 | –25 | 0 | +21 | +3 | +28 | +3 | +33 | +15 | +40 | +15 | +45 | +27 |

| –46 | –3 | –53 | –3 | –58 | –15 | –65 | –15 | –70 | –27 | ||||

| –40 | –9 | –46 | –10 | –52 | –21 | –58 | –22 | –64 | –33 | ||||

| 180 | 250 | –30 | 0 | +24 | +4 | +33 | +4 | +37 | +17 | +46 | +17 | +51 | +31 |

| –54 | –4 | –63 | –4 | –67 | –17 | –76 | –17 | –81 | –31 | ||||

| –48 | –10 | –55 | –12 | –61 | –23 | –68 | –25 | –75 | –37 | ||||

| 250 | 315 | –35 | 0 | +27 | +4 | +36 | +4 | +43 | +20 | +52 | +20 | +57 | +34 |

| –62 | –4 | –71 | –4 | –78 | –20 | –87 | –20 | –92 | –34 | ||||

| –54 | –12 | –62 | –13 | –70 | –28 | –78 | –29 | –84 | –42 | ||||

| 315 | 400 | –40 | 0 | +29 | +4 | +40 | +4 | +46 | +21 | +57 | +21 | +62 | +37 |

| –69 | –4 | –80 | –4 | –86 | –21 | –97 | –21 | –102 | –37 | ||||

| –61 | –12 | –69 | –15 | –78 | –29 | –86 | –32 | –94 | –45 | ||||

| 400 | 500 | –45 | 0 | +32 | +5 | +45 | +5 | +50 | +23 | +63 | +23 | +67 | +40 |

| –77 | –5 | –90 | –5 | –95 | –23 | –108 | –23 | –112 | –40 | ||||

| –68 | –14 | –78 | –17 | –86 | –32 | –96 | –35 | –103 | –49 | ||||

| 500 | 630 | –50 | 0 | +29 | 0 | +44 | 0 | +55 | +26 | +70 | +26 | +73 | +44 |

| –78 | 0 | –94 | 0 | –105 | –26 | –120 | –26 | –122 | –44 | ||||

| –68 | –10 | –81 | –13 | –94 | –36 | –107 | –39 | –112 | –54 | ||||

| 630 | 800 | –75 | 0 | +32 | 0 | +50 | 0 | +62 | +30 | +80 | +30 | +82 | +50 |

| –107 | 0 | –125 | 0 | –137 | –30 | –155 | –30 | –157 | –50 | ||||

| –95 | –12 | –108 | –17 | –125 | –42 | –138 | –47 | –145 | –62 | ||||

| 800 | 1 000 | –100 | 0 | +36 | 0 | +56 | 0 | +70 | +34 | +90 | +34 | +92 | +56 |

| –136 | 0 | –156 | 0 | –170 | –34 | –190 | –34 | –192 | –56 | ||||

| –122 | –14 | –136 | –20 | –156 | –48 | –170 | –54 | –178 | –70 | ||||

| 1 000 | 1 250 | –125 | 0 | +42 | 0 | +66 | 0 | +82 | +40 | +106 | +40 | +108 | +66 |

| –167 | 0 | –191 | 0 | –207 | –40 | –231 | –40 | –233 | –66 | ||||

| –150 | –17 | –167 | –24 | –190 | –57 | –207 | –64 | –216 | –83 | ||||

| 1 250 | 1 600 | –160 | 0 | +50 | 0 | +78 | 0 | +98 | +48 | +126 | +48 | +128 | +78 |

| –210 | 0 | –238 | 0 | –258 | –48 | –286 | –48 | –288 | –78 | ||||

| –189 | –21 | –208 | –30 | –237 | –69 | –256 | –78 | –267 | –99 | ||||

| 1 600 | 2 000 | –200 | 0 | +60 | 0 | +92 | 0 | +118 | +58 | +150 | +58 | +152 | +92 |

| –260 | 0 | –292 | 0 | –318 | –58 | –350 | –58 | –352 | –92 | ||||

| –235 | –25 | –257 | –35 | –293 | –83 | –315 | –93 | –327 | –117 | ||||

|

Shaft Nominal diameter |

Bearing Bore diameter tolerance |

Shaft diameter deviations, resultant fits1) Tolerance classes |

||||||||||||

| d | tΔdmp | n6 | p6 | p7 | r6 | r7 | ||||||||

| Deviations (shaft diameter) | ||||||||||||||

| Theoretical interference (–)/clearance (+) | ||||||||||||||

| over | incl. | low | high | Probable interference (–) | ||||||||||

| mm | µm | µm | ||||||||||||

| 50 | 80 | –15 | 0 | +39 | +20 | +51 | +32 | +62 | +32 | – | – | – | – | |

| –54 | –20 | –66 | –32 | –77 | –32 | – | – | – | – | |||||

| –50 | –24 | –62 | –36 | –72 | –38 | – | – | – | – | |||||

| 80 | 100 | –20 | 0 | +45 | +23 | +59 | +37 | +72 | +37 | +73 | +51 | +86 | +51 | |

| –65 | –23 | –79 | –37 | –92 | –37 | –93 | –51 | –106 | –51 | |||||

| –59 | –29 | –73 | –43 | –85 | –44 | –87 | –57 | –99 | –58 | |||||

| 100 | 120 | –20 | 0 | +45 | +23 | +59 | +37 | +72 | +37 | +76 | +54 | +89 | +54 | |

| –65 | –23 | –79 | –37 | –92 | –37 | –96 | –54 | –109 | –54 | |||||

| –59 | –29 | –73 | –43 | –85 | –44 | –90 | –60 | –102 | –61 | |||||

| 120 | 140 | –25 | 0 | +52 | +27 | +68 | +43 | +83 | +43 | +88 | +63 | +103 | +63 | |

| –77 | –27 | –93 | –43 | –108 | –43 | –113 | –63 | –128 | –63 | |||||

| –70 | –34 | –86 | –50 | –100 | –51 | –106 | –70 | –120 | –71 | |||||

| 140 | 160 | –25 | 0 | +52 | +27 | +68 | +43 | +83 | +43 | +90 | +65 | +105 | +65 | |

| –77 | –27 | –93 | –43 | –108 | –43 | –115 | –65 | –130 | –65 | |||||

| –70 | –34 | –86 | –50 | –100 | –51 | –108 | –72 | –122 | –73 | |||||

| 160 | 180 | –25 | 0 | +52 | +27 | +68 | +43 | +83 | +43 | +93 | +68 | +108 | +68 | |

| –77 | –27 | –93 | –43 | –108 | –43 | –118 | –68 | –133 | –68 | |||||

| –70 | –34 | –86 | –50 | –100 | –51 | –111 | –75 | –125 | –76 | |||||

| 180 | 200 | –30 | 0 | +60 | +31 | +79 | +50 | +96 | +50 | +106 | +77 | +123 | +77 | |

| –90 | –31 | –109 | –50 | –126 | –50 | –136 | –77 | –153 | –77 | |||||

| –82 | –39 | –101 | –58 | –116 | –60 | –128 | –85 | –143 | –87 | |||||

| 200 | 225 | –30 | 0 | +60 | +31 | +79 | +50 | +96 | +50 | +109 | +80 | +126 | +80 | |

| –90 | –31 | –109 | –50 | –126 | –50 | –139 | –80 | –156 | ||||||

| –82 | –39 | –101 | –58 | –116 | –60 | –131 | –88 | –146 | –90 | |||||

| 225 | 250 | –30 | 0 | +60 | +31 | +79 | +50 | +96 | +50 | +113 | +84 | +130 | +84 | |

| –90 | –31 | –109 | –50 | –126 | –50 | –143 | –84 | –160 | –84 | |||||

| –82 | –39 | –101 | –58 | –116 | –60 | –135 | –92 | –150 | –94 | |||||

| 250 | 280 | –35 | 0 | +66 | +34 | +88 | +56 | +108 | +56 | +126 | +94 | +146 | +94 | |

| –101 | –34 | –123 | –56 | –143 | –56 | –161 | –94 | –181 | –94 | |||||

| –92 | –43 | –114 | –65 | –131 | –68 | –152 | –103 | –169 | –106 | |||||

| 280 | 315 | –35 | 0 | +66 | +34 | +88 | +56 | +108 | +56 | +130 | +98 | +150 | +98 | |

| –101 | –34 | –123 | –56 | –143 | –56 | –165 | –98 | –185 | –98 | |||||

| –92 | –43 | –114 | –65 | –131 | –68 | –156 | –107 | –173 | –110 | |||||

| 315 | 355 | –40 | 0 | +73 | +37 | +98 | +62 | +119 | +62 | +144 | +108 | +165 | +108 | |

| –113 | –37 | –138 | –62 | –159 | –62 | –184 | –108 | –205 | –108 | |||||

| –102 | –48 | –127 | –73 | –146 | –75 | –173 | –119 | –192 | –121 | |||||

| 355 | 400 | –40 | 0 | +73 | +37 | +98 | +62 | +119 | +62 | +150 | +114 | +171 | +114 | |

| –113 | –37 | –138 | –62 | –159 | –62 | –190 | –114 | –211 | –114 | |||||

| –102 | –48 | –127 | –73 | –146 | –75 | –179 | –125 | –198 | –127 | |||||

| 400 | 450 | –45 | 0 | +80 | +40 | +108 | +68 | +131 | +68 | +166 | +126 | +189 | +126 | |

| –125 | –40 | –153 | –68 | –176 | –68 | –211 | –126 | –234 | –126 | |||||

| –113 | –52 | –141 | –80 | –161 | –83 | –199 | –138 | –219 | –141 | |||||

| 450 | 500 | –45 | 0 | +80 | +40 | +108 | +68 | +131 | +68 | +172 | +132 | +195 | +132 | |

| –125 | –40 | –153 | –68 | –176 | –68 | –217 | –132 | –240 | –132 | |||||

| –113 | –52 | –141 | –80 | –161 | –83 | –205 | –144 | –225 | –147 | |||||

| 500 | 560 | –50 | 0 | +88 | +44 | +122 | +78 | +148 | +78 | +194 | +150 | +220 | +150 | |

| –138 | –44 | –172 | –78 | –198 | –78 | –244 | –150 | –270 | –150 | |||||

| –125 | –57 | –159 | –91 | –182 | –94 | –231 | –163 | –254 | –166 | |||||

| 560 | 630 | –50 | 0 | +88 | +44 | +122 | +78 | +148 | +78 | +199 | +155 | +225 | +155 | |

| –138 | –44 | –172 | –78 | –198 | –78 | –249 | –155 | –275 | –155 | |||||

| –125 | –57 | –159 | –91 | –182 | –94 | –236 | –168 | –259 | –171 | |||||

| 630 | 710 | –75 | 0 | +100 | +50 | +138 | +88 | +168 | +88 | +225 | +175 | +255 | +175 | |

| –175 | –50 | –213 | –88 | –243 | –88 | –300 | –175 | –330 | –175 | |||||

| –158 | –67 | –196 | –105 | –221 | –110 | –283 | –192 | –308 | –197 | |||||

| 710 | 800 | –75 | 0 | +100 | +50 | +138 | +88 | +168 | +88 | +235 | +185 | +265 | +185 | |

| –175 | –50 | –213 | –88 | –243 | –88 | –310 | –185 | –340 | –185 | |||||

| –158 | –67 | –196 | –105 | –221 | –110 | –293 | –202 | –318 | –207 | |||||

| 800 | 900 | –100 | 0 | +112 | +56 | +156 | +100 | +190 | +100 | +266 | +210 | +300 | +210 | |

| –212 | –56 | –256 | –100 | –290 | –100 | –366 | –210 | –400 | –210 | |||||

| –192 | –76 | –236 | –120 | –263 | –127 | –346 | –230 | –373 | –237 | |||||

| 900 | 1 000 | –100 | 0 | +112 | +56 | +156 | +100 | +190 | +100 | +276 | +220 | +310 | +220 | |

| –212 | –56 | –256 | –100 | –290 | –100 | –376 | –220 | –410 | –220 | |||||

| –192 | –76 | –236 | –120 | –263 | –127 | –356 | –240 | –383 | –247 | |||||

| 1 000 | 1 120 | –125 | 0 | +132 | +66 | +186 | +120 | +225 | +120 | +316 | +250 | +355 | +250 | |

| –257 | –66 | –311 | –120 | –350 | –120 | –441 | –250 | –480 | –250 | |||||

| –233 | –90 | –287 | –144 | –317 | –153 | –417 | –274 | –447 | –283 | |||||

| 1 120 | 1 250 | –125 | 0 | +132 | +66 | +186 | +120 | +225 | +120 | +326 | +260 | +365 | +260 | |

| –257 | –66 | –311 | –120 | –350 | –120 | –451 | –260 | –490 | –260 | |||||

| –233 | –90 | –287 | –144 | –317 | –153 | –427 | –284 | –457 | –293 | |||||

| 1 250 | 1 400 | –160 | 0 | +156 | +78 | +218 | +140 | +265 | +140 | +378 | +300 | +425 | +300 | |

| –316 | –78 | –378 | –140 | –425 | –140 | –538 | –300 | –585 | –300 | |||||

| –286 | –108 | –348 | –170 | –385 | –180 | –508 | –330 | –545 | –340 | |||||

| 1 400 | 1 600 | –160 | 0 | +156 | +78 | +218 | +140 | +265 | +140 | +408 | +330 | +455 | +330 | |

| –316 | –78 | –378 | –140 | –425 | –140 | –568 | –330 | –615 | –330 | |||||

| –286 | –108 | –348 | –170 | –385 | –180 | –538 | –360 | –575 | –370 | |||||

| 1 600 | 1 800 | –200 | 0 | +184 | +92 | +262 | +170 | +320 | +170 | +462 | +370 | +520 | +370 | |

| –384 | –92 | –462 | –170 | –520 | –170 | –662 | –370 | –720 | –370 | |||||

| –349 | –127 | –427 | –205 | –470 | –220 | –627 | –405 | –670 | –420 | |||||

| 1 800 | 2 000 | –200 | 0 | +184 | +92 | +262 | +170 | +320 | +170 | +492 | +400 | +550 | +400 | |

| –384 | –92 | –462 | –170 | –520 | –170 | –692 | –400 | –750 | –400 | |||||

| –349 | –127 | –427 | –205 | –470 | –220 | –657 | –435 | –700 | –450 | |||||

|

Shaft Nominal diameter |

Bearing Bore diameter tolerance |

Shaft diameter deviations, resultant fits Tolerance classes |

|||||||||||

| d | tΔdmp | r6+IT6 | r7+IT7 | ||||||||||

| Deviations (shaft diameter) | |||||||||||||

| Theoretical interference (–) | |||||||||||||

| over | incl. | low | high | Probable interference (–) | |||||||||

| mm | µm | µm | |||||||||||

| 315 | 355 | –40 | 0 | +180 | +144 | +222 | +165 | ||||||

| –220 | –144 | –262 | –165 | ||||||||||

| –209 | –155 | –248 | –179 | ||||||||||

| 355 | 400 | –40 | 0 | +186 | +150 | +228 | +171 | ||||||

| –226 | –150 | –268 | –171 | ||||||||||

| –215 | –161 | –254 | –185 | ||||||||||

| 400 | 450 | –45 | 0 | +206 | +166 | +252 | +189 | ||||||

| –251 | –166 | –297 | –189 | ||||||||||

| –239 | –178 | –282 | –204 | ||||||||||

| 450 | 500 | –45 | 0 | +212 | +172 | +258 | +195 | ||||||

| –257 | –172 | –303 | –195 | ||||||||||

| –245 | –184 | –288 | –210 | ||||||||||

| 500 | 560 | –50 | 0 | +238 | +194 | +290 | +220 | ||||||

| –288 | –194 | –340 | –220 | ||||||||||

| –274 | –208 | –323 | –237 | ||||||||||

| 560 | 630 | –50 | 0 | +243 | +199 | +295 | +225 | ||||||

| –293 | –199 | –345 | –225 | ||||||||||

| –279 | –213 | –328 | –242 | ||||||||||

| 630 | 710 | –75 | 0 | +275 | +225 | +335 | +255 | ||||||

| –350 | –225 | –410 | –255 | ||||||||||

| –333 | –242 | –387 | –278 | ||||||||||

| 710 | 800 | –75 | 0 | +285 | +235 | +345 | +265 | ||||||

| –360 | –235 | –420 | –265 | ||||||||||

| –343 | –252 | –397 | –288 | ||||||||||

| 800 | 900 | –100 | 0 | +322 | +266 | +390 | +300 | ||||||

| –422 | –266 | –490 | –300 | ||||||||||

| –401 | –287 | –462 | –328 | ||||||||||

| 900 | 1 000 | –100 | 0 | +332 | +276 | +400 | +310 | ||||||

| –432 | –276 | –500 | –310 | ||||||||||

| –411 | –297 | –472 | –338 | ||||||||||

| 1 000 | 1 120 | –125 | +382 | +316 | +460 | +355 | |||||||

| –507 | –316 | –585 | –355 | ||||||||||

| –482 | –341 | –552 | –388 | ||||||||||

| 1 120 | 1 250 | –125 | 0 | +392 | +326 | +470 | +365 | ||||||

| –517 | –326 | –595 | –365 | ||||||||||

| –492 | –351 | –562 | –398 | ||||||||||

| 1 250 | 1 400 | –160 | 0 | +456 | +378 | +550 | +425 | ||||||

| –616 | –378 | –710 | –425 | ||||||||||

| –586 | –408 | –669 | –466 | ||||||||||

| 1 400 | 1 600 | –160 | 0 | +486 | +408 | +580 | +455 | ||||||

| –646 | –408 | –740 | –455 | ||||||||||

| –616 | –438 | –699 | –496 | ||||||||||

| 1 600 | 1 800 | –200 | 0 | +554 | +462 | +670 | +520 | ||||||

| –754 | –462 | –870 | –520 | ||||||||||

| –718 | –498 | –820 | –570 | ||||||||||

| 1 800 | 2 000 | –200 | 0 | +584 | +492 | +700 | +550 | ||||||

| –784 | –492 | –900 | –550 | ||||||||||

| –748 | –528 | –850 | –600 | ||||||||||

The appropriate values for housing seats are listed for the following tolerance classes:

|

Housing Nominal bore diameter |

Bearing Outside diameter tolerance |

Housing bore diameter deviations, resultant fits Tolerance classes |

|||||||||||

| D | tΔDmp | F7 | G6 | G7 | H5 | H6 | |||||||

| Deviations (housing bore diameter) | |||||||||||||

| Theoretical clearance (+) | |||||||||||||

| over | incl. | low | high | Probable clearance (+) | |||||||||

| mm | µm | µm | |||||||||||

| 6 | 10 | 0 | –8 | +13 | +28 | +5 | +14 | +5 | +20 | 0 | +6 | 0 | +9 |

| +13 | +36 | +5 | +22 | +5 | +28 | 0 | +14 | 0 | +17 | ||||

| +16 | +33 | +7 | +20 | +8 | +25 | +2 | +12 | +2 | +15 | ||||

| 10 | 18 | 0 | –8 | +16 | +34 | +6 | +17 | +6 | +24 | 0 | +8 | 0 | +11 |

| +16 | +42 | +6 | +25 | +6 | +32 | 0 | +16 | 0 | +19 | ||||

| +19 | +39 | +8 | +23 | +9 | +29 | +2 | +14 | +2 | +17 | ||||

| 18 | 30 | 0 | –9 | +20 | +41 | +7 | +20 | +7 | +28 | 0 | +9 | +0 | +13 |

| +20 | +50 | +7 | +29 | +7 | +37 | 0 | +18 | 0 | +22 | ||||

| +23 | +47 | +10 | +26 | +10 | +34 | +2 | +16 | +3 | +19 | ||||

| 30 | 50 | 0 | –11 | +25 | +50 | +9 | +25 | +9 | +34 | 0 | +11 | 0 | +16 |

| +25 | +61 | +9 | +36 | +9 | +45 | 0 | +22 | 0 | +27 | ||||

| +29 | +57 | +12 | +33 | +13 | +41 | +3 | +19 | +3 | +24 | ||||

| 50 | 80 | 0 | –13 | +30 | +60 | +10 | +29 | +10 | +40 | 0 | +13 | 0 | +19 |

| +30 | +73 | +10 | +42 | +10 | +53 | 0 | +26 | 0 | +32 | ||||

| +35 | +68 | +14 | +38 | +15 | +48 | +3 | +23 | +4 | +28 | ||||

| 80 | 120 | 0 | –15 | +36 | +71 | +12 | +34 | +12 | +47 | 0 | +15 | 0 | +22 |

| +36 | +86 | +12 | +49 | +12 | +62 | 0 | +30 | 0 | +37 | ||||

| +41 | +81 | +17 | +44 | +17 | +57 | +4 | +26 | +5 | +32 | ||||

| 120 | 150 | 0 | –18 | +43 | +83 | +14 | +39 | +14 | +54 | 0 | +18 | 0 | +25 |

| +43 | +101 | +14 | +57 | +14 | +72 | 0 | +36 | 0 | +43 | ||||

| +50 | +94 | +20 | +51 | +21 | +65 | +5 | +31 | +6 | +37 | ||||

| 150 | 180 | 0 | –25 | +43 | +83 | +14 | +39 | +14 | +54 | 0 | +18 | 0 | +25 |

| +43 | +108 | +14 | +64 | +14 | +79 | 0 | +43 | 0 | +50 | ||||

| +51 | +100 | +21 | +57 | +22 | +71 | +6 | +37 | +7 | +43 | ||||

| 180 | 250 | 0 | –30 | +50 | +96 | +15 | +44 | +15 | +61 | 0 | +20 | 0 | +29 |

| +50 | +126 | +15 | +74 | +15 | +91 | 0 | +50 | 0 | +59 | ||||

| +60 | +116 | +23 | +66 | +25 | +81 | +6 | +44 | +8 | +51 | ||||

| 250 | 315 | 0 | –35 | +56 | +108 | +17 | +49 | +17 | +69 | 0 | +23 | 0 | +32 |

| +56 | +143 | +17 | +84 | +17 | +104 | 0 | +58 | 0 | +67 | ||||

| +68 | +131 | +26 | +75 | +29 | +92 | +8 | +50 | +9 | +58 | ||||

| 315 | 400 | 0 | –40 | +62 | +119 | +18 | +54 | +18 | +75 | 0 | +25 | 0 | +36 |

| +62 | +159 | +18 | +94 | +18 | +115 | 0 | +65 | 0 | +76 | ||||

| +75 | +146 | +29 | +83 | +31 | +102 | +8 | +57 | +11 | +65 | ||||

| 400 | 500 | 0 | –45 | +68 | +131 | +20 | +60 | +20 | +83 | 0 | +27 | 0 | +40 |

| +68 | +176 | +20 | +105 | +20 | +128 | 0 | +72 | 0 | +85 | ||||

| +83 | +161 | +32 | +93 | +35 | +113 | +9 | +63 | +12 | +73 | ||||

| 500 | 630 | 0 | –50 | +76 | +146 | +22 | +66 | +22 | +92 | 0 | +28 | 0 | +44 |

| +76 | +196 | +22 | +116 | +22 | +142 | 0 | +78 | 0 | +94 | ||||

| +92 | +180 | +35 | +103 | +38 | +126 | +10 | +68 | +13 | +81 | ||||

| 630 | 800 | 0 | –75 | +80 | +160 | +24 | +74 | +24 | +104 | 0 | +32 | 0 | +50 |

| +80 | +235 | +24 | +149 | +24 | +179 | 0 | +107 | 0 | +125 | ||||

| +102 | +213 | +41 | +132 | +46 | +157 | +12 | +95 | +17 | +108 | ||||

| 800 | 1 000 | 0 | –100 | +86 | +176 | +26 | +82 | +26 | +116 | 0 | +36 | 0 | +56 |

| +86 | +276 | +26 | +182 | +26 | +216 | 0 | +136 | 0 | +156 | ||||

| +113 | +249 | +46 | +162 | +53 | +189 | +14 | +122 | +20 | +136 | ||||

| 1 000 | 1 250 | 0 | –125 | +98 | +203 | +28 | +94 | +28 | +133 | 0 | +42 | 0 | +66 |

| +98 | +328 | +28 | +219 | +28 | +258 | 0 | +167 | 0 | +191 | ||||

| +131 | +295 | +52 | +195 | +61 | +225 | +17 | +150 | +24 | +167 | ||||

| 1 250 | 1 600 | 0 | –160 | +110 | +235 | +30 | +108 | +30 | +155 | 0 | +50 | 0 | +78 |

| +150 | +355 | +60 | +238 | +70 | +275 | +21 | +189 | +30 | +208 | ||||

| 1 600 | 2 000 | 0 | –200 | +120 | +270 | +32 | +124 | +32 | +182 | 0 | +60 | 0 | +92 |

| +120 | +470 | +32 | +324 | +32 | +382 | 0 | +260 | 0 | +292 | ||||

| +170 | +420 | +67 | +289 | +82 | +332 | +25 | +235 | +35 | +257 | ||||

| 2 000 | 2 500 | 0 | –250 | +130 | +305 | +34 | +144 | +34 | +209 | 0 | +70 | 0 | +110 |

| +130 | +555 | +34 | +394 | +34 | +459 | 0 | +320 | 0 | +360 | ||||

| +189 | +496 | +77 | +351 | +93 | +400 | +30 | +290 | +43 | +317 | ||||

|

Housing Nominal bore diameter |

Bearing Outside diameter tolerance |

Housing bore diameter deviations, resultant fits1) Tolerance classes |

|||||||||||

| D | tΔDmp | H7Ⓔ | H8Ⓔ | H9Ⓔ | H10Ⓔ | J6Ⓔ | |||||||

| Deviations (housing bore diameter) | |||||||||||||

| Theoretical interference (–)/clearance (+) | |||||||||||||

| over | incl. | low | high | Probable interference (–)/clearance (+) | |||||||||

| mm | µm | µm | |||||||||||

| 6 | 10 | 0 | –8 | 0 | +15 | 0 | +22 | 0 | +36 | 0 | +58 | –4 | +5 |

| 0 | +23 | 0 | +30 | 0 | +44 | 0 | +66 | –4 | +13 | ||||

| +3 | +20 | +3 | +27 | +3 | +41 | +3 | +63 | –2 | +11 | ||||

| 10 | 18 | 0 | –8 | 0 | +18 | 0 | +27 | 0 | +43 | 0 | +70 | –5 | +6 |

| 0 | +26 | 0 | +35 | 0 | +51 | 0 | +78 | –5 | +14 | ||||

| +3 | +23 | +3 | +32 | +3 | +48 | +3 | +75 | –3 | +12 | ||||

| 18 | 30 | 0 | –9 | 0 | +21 | 0 | +33 | 0 | +52 | 0 | +84 | –5 | +8 |

| 0 | +30 | 0 | +42 | 0 | +61 | 0 | +93 | –5 | +17 | ||||

| +3 | +27 | +3 | +39 | +4 | +57 | +4 | +89 | –2 | +14 | ||||

| 30 | 50 | 0 | –11 | 0 | +25 | 0 | +39 | 0 | +62 | 0 | +100 | –6 | +10 |

| 0 | +36 | 0 | +50 | 0 | +73 | 0 | +111 | –6 | +21 | ||||

| +4 | +32 | +4 | +46 | +5 | +68 | +5 | +106 | –3 | +18 | ||||

| 50 | 80 | 0 | –13 | 0 | +30 | 0 | +46 | 0 | +74 | 0 | +120 | –6 | +13 |

| 0 | +43 | 0 | +59 | 0 | +87 | 0 | +133 | –6 | +26 | ||||

| +5 | +38 | +5 | +54 | +5 | +82 | +6 | +127 | –2 | +22 | ||||

| 80 | 120 | 0 | –15 | 0 | +35 | 0 | +54 | 0 | +87 | 0 | +140 | –6 | +16 |

| 0 | +50 | 0 | +69 | 0 | +102 | 0 | +155 | –6 | +31 | ||||

| +5 | +45 | +6 | +63 | +6 | +96 | +7 | +148 | –1 | +26 | ||||

| 120 | 150 | 0 | –18 | 0 | +40 | 0 | +63 | 0 | +100 | 0 | +160 | –7 | +18 |

| 0 | +58 | 0 | +81 | 0 | +118 | 0 | +178 | –7 | +36 | ||||

| +7 | +51 | +7 | +74 | +8 | +110 | +8 | +170 | –1 | +30 | ||||

| 150 | 180 | 0 | –25 | 0 | +40 | 0 | +63 | 0 | +100 | 0 | +160 | –7 | +18 |

| 0 | +65 | 0 | +88 | 0 | +125 | 0 | +185 | –7 | +43 | ||||

| +8 | +57 | +10 | +78 | +10 | +115 | +11 | +174 | 0 | +36 | ||||

| 180 | 250 | 0 | –30 | 0 | +46 | 0 | +72 | 0 | +115 | 0 | +185 | –7 | +22 |

| 0 | +76 | 0 | +102 | 0 | +145 | 0 | +215 | –7 | +52 | ||||

| +10 | +66 | +12 | +90 | +13 | +132 | +13 | +202 | +1 | +44 | ||||

| 250 | 315 | 0 | –35 | 0 | +52 | 0 | +81 | 0 | +130 | 0 | +210 | –7 | +25 |

| 0 | +87 | 0 | +116 | 0 | +165 | 0 | +245 | –7 | +60 | ||||

| +12 | +75 | +13 | +103 | +15 | +150 | +16 | +229 | +2 | +51 | ||||

| 315 | 400 | 0 | –40 | 0 | +57 | 0 | +89 | 0 | +140 | 0 | +230 | –7 | +29 |

| 0 | +97 | 0 | +129 | 0 | +180 | 0 | +270 | –7 | +69 | ||||

| +13 | +84 | +15 | +114 | +17 | +163 | +18 | +252 | +4 | +58 | ||||

| 400 | 500 | 0 | –45 | 0 | +63 | 0 | +97 | 0 | +155 | 0 | +250 | –7 | +33 |

| 0 | +108 | 0 | +142 | 0 | +200 | 0 | +295 | –7 | +78 | ||||

| +15 | +93 | +17 | +125 | +19 | +181 | +20 | +275 | +5 | +66 | ||||

| 500 | 630 | 0 | –50 | 0 | +70 | 0 | +110 | 0 | +175 | 0 | +280 | – | – |

| 0 | +120 | 0 | +160 | 0 | +225 | 0 | +330 | – | – | ||||

| +16 | +104 | +19 | +141 | +21 | +204 | +22 | +308 | – | – | ||||

| 630 | 800 | 0 | –75 | 0 | +80 | 0 | +125 | 0 | +200 | 0 | +320 | – | – |

| 0 | +155 | 0 | +200 | 0 | +275 | 0 | +395 | – | – | ||||

| +22 | +133 | +27 | +173 | +30 | +245 | +33 | +362 | – | – | ||||

| 800 | 1 000 | 0 | –100 | 0 | +90 | 0 | +140 | 0 | +230 | 0 | +360 | – | – |

| 0 | +190 | 0 | +240 | 0 | +330 | 0 | +460 | – | – | ||||

| +27 | +163 | +33 | +207 | +39 | +291 | +43 | +417 | – | – | ||||

| 1 000 | 1 250 | 0 | –125 | 0 | +105 | 0 | +165 | 0 | +260 | 0 | +420 | – | – |

| 0 | +230 | 0 | +290 | 0 | +385 | 0 | +545 | – | – | ||||

| +33 | +197 | +41 | +249 | +48 | +337 | +53 | +492 | – | – | ||||

| 1 250 | 1 600 | 0 | –160 | 0 | +125 | 0 | +195 | 0 | +310 | 0 | +500 | – | – |

| 0 | +285 | 0 | +355 | 0 | +470 | 0 | +660 | – | – | ||||

| +40 | +245 | +51 | +304 | +60 | +410 | +67 | +593 | – | – | ||||

| 1 600 | 2 000 | 0 | –200 | 0 | +150 | 0 | +230 | 0 | +370 | 0 | +600 | – | – |

| 0 | +350 | 0 | +430 | 0 | +570 | 0 | +800 | – | – | ||||

| +50 | +300 | +62 | +368 | +74 | +496 | +83 | +717 | – | – | ||||

| 2 000 | 2 500 | 0 | –250 | 0 | +175 | 0 | +280 | 0 | +440 | 0 | +700 | – | – |

| 0 | +425 | 0 | +530 | 0 | +690 | 0 | +950 | – | – | ||||

| +59 | +366 | +77 | +453 | +91 | +599 | +103 | +847 | – | – | ||||

|

Housing Nominal bore diameter |

Bearing Outside diameter tolerance |

Housing bore diameter deviations, resultant fits Tolerance classes |

|||||||||||

| D | tΔDmp | J7 | JS5 | JS6 | JS7 | K5 | |||||||

| Deviations (housing bore diameter) | |||||||||||||

| Theoretical interference (–)/clearance (+) | |||||||||||||

| over | incl. | low | high | Probable interference (–)/clearance (+) | |||||||||

| mm | µm | µm | |||||||||||

| 6 | 10 | 0 | –8 | –7 | +8 | –3 | +3 | –4,5 | +4,5 | –7,5 | +7,5 | –5 | +1 |

| –7 | +16 | –3 | +11 | –4,5 | +12,5 | –7,5 | +15,5 | –5 | +9 | ||||

| –4 | +13 | –1 | +9 | –3 | +11 | –5 | +13 | –3 | +7 | ||||

| 10 | 18 | 0 | –8 | –8 | +10 | –4 | +4 | –5,5 | +5,5 | –9 | +9 | –6 | +2 |

| –8 | +18 | –4 | +12 | –5,5 | +13,5 | –9 | +17 | –6 | +10 | ||||

| –5 | +15 | –2 | +10 | –3 | +11 | –6 | +14 | –4 | +8 | ||||

| 18 | 30 | 0 | –9 | –9 | +12 | –4,5 | +4,5 | –6,5 | +6,5 | –10,5 | +10,5 | –8 | +1 |

| –9 | +21 | –4,5 | +13,5 | –6,5 | +15,5 | –10,5 | +19,5 | –8 | +10 | ||||

| –6 | +18 | –2 | +11 | –4 | +13 | –7 | +16 | –6 | +8 | ||||

| 30 | 50 | 0 | –11 | –11 | +14 | –5,5 | +5,5 | –8 | +8 | –12,5 | +12,5 | –9 | +2 |

| –11 | +25 | –5,5 | –8 | +19 | –12,5 | +23,5 | –9 | +13 | |||||

| –7 | +21 | –3 | +14 | –5 | +16 | –9 | +20 | –6 | +10 | ||||

| 50 | 80 | 0 | –13 | –12 | +18 | –6,5 | +6,5 | –9,5 | +9,5 | –15 | +15 | –10 | +3 |

| –12 | +31 | –6,5 | +19,5 | –9,5 | +22,5 | –15 | +28 | –10 | +16 | ||||

| –7 | +26 | –3 | +16 | –6 | +19 | –10 | +23 | –7 | +13 | ||||

| 80 | 120 | 0 | –15 | –13 | +22 | –7,5 | +7,5 | –11 | +11 | –17,5 | +17,5 | –13 | +2 |

| –13 | +37 | –7,5 | +22,5 | –11 | +26 | –17,5 | +32,5 | –13 | +17 | ||||

| –8 | +32 | –4 | +19 | –6 | +21 | –12 | +27 | –9 | +13 | ||||

| 120 | 150 | 0 | –18 | –14 | +26 | –9 | +9 | –12,5 | +12,5 | –20 | +20 | –15 | +3 |

| –14 | +44 | –9 | +27 | –12,5 | +30,5 | –20 | +38 | –15 | +21 | ||||

| –7 | +37 | –4 | +22 | –7 | +25 | –13 | +31 | –10 | +16 | ||||

| 150 | 180 | 0 | –25 | –14 | +26 | –9 | +9 | –12,5 | +12,5 | –20 | +20 | –15 | +3 |

| –14 | +51 | –9 | +34 | –12,5 | +37,5 | –20 | +45 | –15 | x+28 | ||||

| –6 | +43 | –3 | +28 | –6 | +31 | –12 | +37 | –9 | +22 | ||||

| 180 | 250 | 0 | –30 | –16 | +30 | –10 | +10 | –14,5 | +14,5 | –23 | +23 | –18 | +2 |

| –16 | +60 | –10 | +40 | –14,5 | +44,5 | –23 | +53 | –18 | +32 | ||||

| –6 | +50 | –4 | +34 | –6 | +36 | –13 | +43 | –12 | +26 | ||||

| 250 | 315 | 0 | –35 | –16 | +36 | –11,5 | +11,5 | –16 | +16 | –26 | +26 | –20 | +3 |

| –16 | +71 | –11,5 | +46,5 | –16 | –51 | –26 | +61 | –20 | +38 | ||||

| –4 | +59 | –4 | +39 | –7 | +42 | –14 | +49 | –12 | +30 | ||||

| 315 | 400 | 0 | –40 | –18 | +39 | –12,5 | +12,5 | –18 | +18 | –28,5 | +28,5 | –22 | +3 |

| –18 | +79 | –12,5 | +52,5 | –18 | +58 | –28,5 | +68,5 | –22 | +43 | ||||

| –5 | +66 | –4 | +44 | –7 | +47 | –15 | +55 | –14 | +35 | ||||

| 400 | 500 | 0 | –45 | –20 | +43 | –13,5 | +13,5 | –20 | +20 | –31,5 | +31,5 | –25 | +2 |

| –20 | +88 | –13,5 | +58,5 | –20 | +65 | –31,5 | +76,5 | –25 | +47 | ||||

| –5 | +73 | –4 | +49 | –8 | +53 | –17 | +62 | –16 | +38 | ||||

| 500 | 630 | 0 | –50 | – | – | –14 | +14 | –22 | +22 | –35 | +35 | – | – |

| – | – | –14 | +64 | –22 | +72 | –35 | +85 | – | – | ||||

| – | – | –4 | +54 | –9 | +59 | –19 | +69 | – | – | ||||

| 630 | 800 | 0 | –75 | – | – | –16 | +16 | –25 | +25 | –40 | +40 | – | – |

| – | – | –16 | +91 | –25 | +100 | –40 | +115 | – | – | ||||

| – | – | –4 | +79 | –8 | +83 | –18 | +93 | – | – | ||||

| 800 | 1 000 | 0 | –100 | – | – | –18 | +18 | –28 | +28 | –45 | +45 | – | – |

| – | – | –18 | +118 | –28 | +128 | –45 | +145 | – | – | ||||

| – | – | –4 | +104 | –8 | +108 | –18 | +118 | – | – | ||||

| 1 000 | 1 250 | 0 | –125 | – | – | –21 | +21 | –33 | +33 | –52 | +52 | – | – |

| – | – | –21 | +146 | –33 | +158 | –52 | +177 | – | – | ||||

| – | – | –4 | +129 | –9 | +134 | –20 | +145 | – | – | ||||

| 1 250 | 1 600 | 0 | –160 | – | – | –25 | +25 | –39 | +39 | –62 | +62 | – | – |

| – | – | –25 | +185 | –39 | +199 | –62 | +222 | – | – | ||||

| – | – | –4 | +164 | –9 | +169 | –22 | +182 | – | – | ||||

| 1 600 | 2 000 | 0 | –200 | – | – | –30 | +30 | –46 | +46 | –75 | +75 | – | – |

| – | – | –30 | +230 | –46 | +246 | –75 | +275 | – | – | ||||

| – | – | –5 | +205 | –11 | +211 | –25 | +225 | – | – | ||||

| 2 000 | 2 500 | 0 | –250 | – | – | –35 | +35 | –55 | +55 | –87 | +87 | – | – |

| – | – | –35 | +285 | –55 | +305 | –87 | +337 | – | – | ||||

| – | – | –5 | +255 | –12 | +262 | –28 | +278 | – | – | ||||

|

Housing Nominal bore diameter |

Bearing Outside diameter tolerance |

Housing bore diameter deviations, resultant fits Tolerance classes |

|||||||||||

| D | tΔDmp | K6 | K7 | M5 | M6 | M7 | |||||||

| Deviations (housing bore diameter) | |||||||||||||

| Theoretical interference (–)/clearance (+) | |||||||||||||

| over | incl. | low | high | Probable interference (–)/clearance (+) | |||||||||

| mm | µm | µm | |||||||||||

| 6 | 10 | 0 | –8 | –7 | +2 | –10 | +5 | –10 | –4 | –12 | –3 | –15 | 0 |

| –7 | +10 | –10 | +13 | –10 | +4 | –12 | +5 | –15 | +8 | ||||

| –5 | +8 | –7 | +10 | –8 | +2 | –10 | +3 | –12 | +5 | ||||

| 10 | 18 | 0 | –8 | –9 | +2 | –12 | +6 | –12 | –4 | –15 | –4 | –18 | 0 |

| –9 | +10 | –12 | +14 | –12 | +4 | –15 | +4 | –18 | +8 | ||||

| –7 | +8 | –9 | +11 | –10 | +2 | –13 | +2 | –15 | +5 | ||||

| 18 | 30 | 0 | –9 | –11 | +2 | –15 | +6 | –14 | –4 | –17 | –4 | –21 | 0 |

| –11 | +11 | –15 | +15 | –14 | +4 | –17 | +5 | –21 | +9 | ||||

| –8 | +8 | –12 | +12 | –12 | +2 | –14 | +2 | –18 | +6 | ||||

| 30 | 50 | 0 | –11 | –13 | +3 | –18 | +7 | –16 | –5 | –20 | –4 | –25 | 0 |

| –13 | +14 | –18 | +18 | –16 | +6 | –20 | +7 | –25 | +11 | ||||

| –10 | +11 | –14 | +14 | –13 | +3 | –17 | +4 | –21 | +7 | ||||

| 50 | 80 | 0 | –13 | –15 | +4 | –21 | +9 | –19 | –6 | –24 | –5 | –30 | 0 |

| –15 | +17 | –21 | +22 | –19 | +7 | –24 | +8 | –30 | +13 | ||||

| –11 | +13 | –16 | +17 | –16 | +4 | –20 | +4 | –25 | +8 | ||||

| 80 | 120 | 0 | –15 | –18 | +4 | –25 | +10 | –23 | –8 | –28 | –6 | –35 | 0 |

| –18 | +19 | –25 | +25 | –23 | +7 | –28 | +9 | –35 | +15 | ||||

| –13 | +14 | –20 | +20 | –19 | +3 | –23 | +4 | –30 | +10 | ||||

| 120 | 150 | 0 | –18 | –21 | +4 | –28 | +12 | –27 | –9 | –33 | –8 | –40 | 0 |

| –21 | +22 | –28 | +30 | –27 | +9 | –33 | +10 | –40 | +18 | ||||

| –15 | +16 | –21 | +23 | –22 | +4 | –27 | +4 | –33 | +11 | ||||

| 150 | 180 | 0 | –25 | –21 | +4 | –28 | +12 | –27 | –9 | –33 | –8 | –40 | 0 |

| –21 | +29 | –28 | +37 | –27 | +16 | –33 | +17 | –40 | +25 | ||||

| –14 | +22 | –20 | +29 | –21 | +10 | –26 | +10 | –32 | +17 | ||||

| 180 | 250 | 0 | –30 | –24 | +5 | –33 | +13 | –31 | –11 | –37 | –8 | –46 | 0 |

| –24 | +35 | –33 | +43 | –31 | +19 | –37 | +22 | –46 | +30 | ||||

| –16 | +27 | –23 | +33 | –25 | +13 | –29 | +14 | –36 | +20 | ||||

| 250 | 315 | 0 | –35 | –27 | +5 | –36 | +16 | –36 | –13 | –41 | –9 | –52 | 0 |

| –27 | +40 | –36 | +51 | –36 | +22 | –41 | +26 | –52 | +35 | ||||

| –18 | +31 | –24 | +39 | –28 | +14 | –32 | +17 | –40 | +23 | ||||

| 315 | 400 | 0 | –40 | –29 | +7 | –40 | +17 | –39 | –14 | –46 | –10 | –57 | 0 |

| –29 | +47 | –40 | +57 | –39 | +26 | –46 | +30 | –57 | +40 | ||||

| –18 | +36 | –27 | +44 | –31 | +18 | –35 | +19 | –44 | +27 | ||||

| 400 | 500 | 0 | –45 | –32 | +8 | –45 | +18 | –43 | –16 | –50 | –10 | –63 | 0 |

| –32 | +53 | –45 | +63 | –43 | +29 | –50 | +35 | –63 | +45 | ||||

| –20 | +41 | –30 | +48 | –34 | +20 | –38 | +23 | –48 | +30 | ||||

| 500 | 630 | 0 | –50 | –44 | 0 | –70 | 0 | – | – | –70 | –26 | –96 | –26 |

| –44 | +50 | –70 | +50 | – | – | –70 | +24 | –96 | +24 | ||||

| –31 | +37 | –54 | +34 | – | – | –57 | +11 | –80 | +8 | ||||

| 630 | 800 | 0 | –75 | –50 | 0 | –80 | 0 | – | – | –80 | –30 | –110 | –30 |

| –50 | +75 | –80 | +75 | – | – | –80 | +45 | –110 | +45 | ||||

| –33 | +58 | –58 | +53 | – | – | –63 | +28 | –88 | +23 | ||||

| 800 | 1 000 | 0 | –100 | –56 | 0 | –90 | 0 | – | – | –90 | –34 | –124 | –34 |

| –56 | +100 | –90 | +100 | – | – | –90 | +66 | –124 | +66 | ||||

| –36 | +80 | –63 | +73 | – | – | –70 | +46 | –97 | +39 | ||||

| 1 000 | 1 250 | 0 | –125 | –66 | 0 | –105 | 0 | – | – | –106 | –40 | –145 | –40 |

| –66 | +125 | –105 | +125 | – | – | –106 | +85 | –145 | +85 | ||||

| –42 | +101 | –72 | +92 | – | – | –82 | +61 | –112 | +52 | ||||

| 1 250 | 1 600 | 0 | –160 | –78 | 0 | –125 | 0 | – | – | –126 | –48 | –173 | –48 |

| –78 | +160 | –125 | +160 | – | – | –126 | +112 | –173 | +112 | ||||

| –48 | +130 | –85 | +120 | – | – | –96 | +82 | –133 | +72 | ||||

| 1 600 | 2 000 | 0 | –200 | –92 | 0 | –150 | 0 | – | – | –158 | –58 | –208 | –58 |

| –92 | +200 | –150 | +200 | – | – | –150 | +142 | –208 | +142 | ||||

| –57 | +165 | –100 | +150 | – | – | –115 | +107 | –158 | +92 | ||||

| 2 000 | 2 500 | 0 | –250 | –110 | 0 | –175 | 0 | – | – | –178 | –68 | –243 | –68 |

| –110 | +250 | –175 | +250 | – | – | –178 | +182 | –243 | +182 | ||||

| –67 | +207 | –116 | +191 | – | – | –135 | +139 | –184 | +123 | ||||

|

Housing Nominal bore diameter |

Bearing Outside diameter tolerance |

Housing bore diameter deviations, resultant fits1) Tolerance classes |

|||||||||||

| D | tΔDmp | N6 | N7 | P6 | P7 | ||||||||

| Deviations (housing bore diameter) | |||||||||||||

| Theoretical interference (–)/clearance (+) | |||||||||||||

| over | incl. | low | high | Probable interference (–)/clearance (+) | |||||||||

| mm | µm | µm | |||||||||||

| 6 | 10 | 0 | –8 | –16 | –7 | –19 | –4 | –21 | –12 | –24 | –9 | ||

| –16 | +1 | –19 | +4 | –21 | –4 | –24 | –1 | ||||||

| –14 | –1 | –16 | +1 | –19 | –6 | –21 | –4 | ||||||

| 10 | 18 | 0 | –8 | –20 | –9 | –23 | –5 | –26 | –15 | –29 | –11 | ||

| –20 | –1 | –23 | +3 | –26 | –7 | –29 | –3 | ||||||

| –18 | –3 | –20 | 0 | –24 | –9 | –26 | –6 | ||||||

| 18 | 30 | 0 | –9 | –24 | –11 | –28 | –7 | –31 | –18 | –35 | –14 | ||

| –24 | –2 | –28 | +2 | –31 | –9 | –35 | –5 | ||||||

| –21 | –5 | –25 | –1 | –28 | –12 | –32 | –8 | ||||||

| 30 | 50 | 0 | –11 | –28 | –12 | –33 | –8 | –37 | –21 | –42 | –17 | ||

| –28 | –1 | –33 | +3 | –37 | –10 | –42 | –6 | ||||||

| –25 | –4 | –29 | –1 | –34 | –13 | –38 | –10 | ||||||

| 50 | 80 | 0 | –13 | –33 | –14 | –39 | –9 | –45 | –26 | –51 | –21 | ||

| –33 | –1 | –39 | +4 | –45 | –13 | –51 | –8 | ||||||

| –29 | –5 | –34 | –1 | –41 | –17 | –46 | –13 | ||||||

| 80 | 120 | 0 | –15 | –38 | –16 | –45 | –10 | –52 | –30 | –59 | –24 | ||

| –38 | –1 | –45 | +5 | –52 | –15 | –59 | –9 | ||||||

| –33 | –6 | –40 | 0 | –47 | –20 | –54 | –14 | ||||||

| 120 | 150 | 0 | –18 | –45 | –20 | –52 | –12 | –61 | –36 | –68 | –28 | ||

| –45 | –2 | –52 | +6 | –61 | –18 | –68 | –10 | ||||||

| –39 | –8 | –45 | –1 | –55 | –24 | –61 | –17 | ||||||

| 150 | 180 | 0 | –25 | –45 | –20 | –52 | –12 | –61 | –36 | –68 | –28 | ||

| –45 | +5 | –52 | +13 | –61 | –11 | –68 | –3 | ||||||

| –38 | –2 | –44 | +5 | –54 | –18 | –60 | –11 | ||||||

| 180 | 250 | 0 | –30 | –51 | –22 | –60 | –14 | –70 | –41 | –79 | –33 | ||

| –51 | +8 | –60 | +16 | –70 | –11 | –79 | –3 | ||||||

| –43 | 0 | –50 | +6 | –62 | –19 | –69 | –13 | ||||||

| 250 | 315 | 0 | –35 | –57 | –25 | –66 | –14 | –79 | –47 | –88 | –36 | ||

| –57 | +10 | –66 | +21 | –79 | –12 | –88 | –1 | ||||||

| –48 | +1 | –54 | +9 | –70 | –21 | –76 | –13 | ||||||

| 315 | 400 | 0 | –40 | –62 | –26 | –73 | –16 | –87 | –51 | –98 | –41 | ||

| –62 | +14 | –73 | +24 | –87 | –11 | –98 | –1 | ||||||

| –51 | +3 | –60 | +11 | –76 | –22 | –85 | –14 | ||||||

| 400 | 500 | 0 | –45 | –67 | –27 | –80 | –17 | –95 | –55 | –108 | –45 | ||

| –67 | +18 | –80 | +28 | –95 | –10 | –108 | 0 | ||||||

| –55 | +6 | –65 | +13 | –83 | –22 | –93 | –15 | ||||||

| 500 | 630 | 0 | –50 | –88 | –44 | –114 | –44 | –122 | –78 | –148 | –78 | ||

| –88 | +6 | –114 | +6 | –122 | –28 | –148 | –28 | ||||||

| –75 | –7 | –98 | –10 | –109 | –41 | –132 | –44 | ||||||

| 630 | 800 | 0 | –75 | –100 | –50 | –130 | –50 | –138 | –88 | –168 | –88 | ||

| –100 | +25 | –130 | +25 | –138 | –13 | –168 | –13 | ||||||

| –83 | +8 | –108 | +3 | –121 | –30 | –146 | –35 | ||||||

| 800 | 1 000 | 0 | –100 | –112 | –56 | –146 | –56 | –156 | –100 | –190 | –100 | ||

| –112 | +44 | –146 | +44 | –156 | 0 | –190 | 0 | ||||||

| –92 | +24 | –119 | +17 | –136 | –20 | –163 | –27 | ||||||

| 1 000 | 1 250 | 0 | –125 | –132 | –66 | –171 | –66 | –186 | –120 | –225 | –120 | ||

| –132 | +59 | –171 | +59 | –186 | +5 | –225 | +5 | ||||||

| –108 | +35 | –138 | +26 | –162 | –19 | –192 | –28 | ||||||

| 1 250 | 1 600 | 0 | –160 | –156 | –78 | –203 | –78 | –218 | –140 | –265 | –140 | ||

| –156 | +82 | –203 | +82 | –218 | +20 | –265 | +20 | ||||||

| –126 | +52 | –163 | +42 | –188 | –10 | –225 | –20 | ||||||

| 1 600 | 2 000 | 0 | –200 | –184 | –92 | –242 | –92 | –262 | –170 | –320 | –170 | ||

| –184 | +108 | –242 | +108 | –262 | +30 | –320 | +30 | ||||||

| –149 | +73 | –192 | +58 | –227 | –5 | –270 | –20 | ||||||

| 2 000 | 2 500 | 0 | –250 | –220 | –110 | –285 | –110 | –305 | –195 | –370 | –195 | ||

| –220 | +140 | –285 | +140 | –305 | +55 | –370 | +55 | ||||||

| –177 | +97 | –226 | +81 | –262 | +12 | –311 | –4 | ||||||