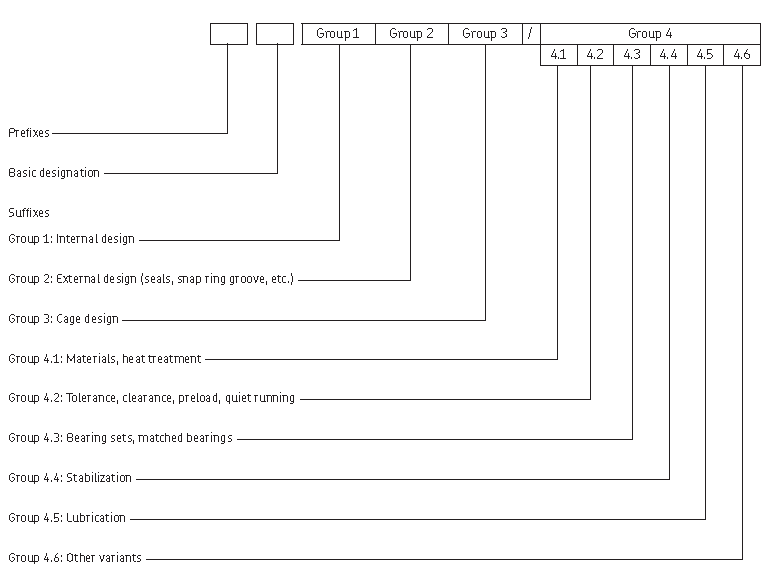

SKF bearing suffix identify designs or variants, which differ in some way from the original design or from the current basic design. The suffixes are divided into groups. When more than one special feature is to be identified, suffixes are provided in the order shown in the table below.

SKF bearing designation system

- Prefixes: please refer to: SKF bearing prefixes

- Basic designation: please refer to: SKF bearing designation

- Group 1: Suffix - Internal design

- Group 2: Suffix - External design (seals, snap ring groove, etc.)

- Group 3: Suffix - Cage design

- Group 4.1: Suffix - Materials, heat treatment

- Group 4.2: Suffix - Tolerance, clearance, preload, quiet running

- Group 4.3: Suffix - Bearing sets, matched bearings

- Group 4.4: Suffix - Stabilization

- Group 4.5: Suffix - Lubrication

- Group 4.6: Suffix - Other variants

SKF deep groove ball bearing suffix

| Suffixes - Internal design | |

| A, AA, C, D | Deviating or modified internal design |

| E | Reinforced ball set |

| Suffixes - External design (seals, snap ring groove, etc.) | |

| N | Snap ring groove in the outer ring |

| NR | Snap ring groove in the outer ring, with snap ring |

| N1 | One locating slot (notch) in one outer ring side face |

| R |

Flanged outer ring |

| -RS1, -2RS1 | Contact seal, NBR, on one or both sides |

| -RS2, -2RS2 | Contact seal, FKM, on one or both sides |

| -RSH, -2RSH | Contact seal, NBR, on one or both sides |

| -RSH2, -2RSH2 | Contact seal, FKM, on one or both sides |

| -RSL, -2RSL | Low-friction seal, NBR, on one or both sides |

| -RST, -2RST |

Low-friction seal, NBR, on one or both sides |

| -RZ, -2RZ | Non-contact seal, NBR, on one or both sides |

| -Z, -2Z | Shield on one or both sides |

| -ZNBR | Shield on one side, snap ring groove in the outer ring, with snap ring on the same side as the shield |

| -ZNR | Shield on one side, snap ring groove in the outer ring, with snap ring on the opposite side of the shield |

| -2ZNR | Shield on both sides, snap ring groove in the outer ring, with snap ring |

| -2ZS |

Shield on both sides, held in place by a retaining ring |

| X |

Boundary dimensions not in accordance with ISO dimension series |

| Suffixes - Cage design | |

| – |

|

| M | Machined brass cage, ball centred; different designs or material grades are identified by a number following the M, e.g. M2 |

| MA(S) | Machined brass cage, outer ring centred. The 'S' indicates a lubrication groove in the guiding surface. |

| MB(S) | Machined brass cage, inner ring centred. The 'S' indicates a lubrication groove in the guiding surface. |

| TN | PA66 cage, ball centred |

| TN9 | Glass fibre reinforced PA66 cage, ball centred |

| TN9/VG1561 | Glass fibre reinforced PA46 cage, ball centred |

| TNH | Glass fibre reinforced PEEK cage, ball centred |

| Suffixes - Materials, heat treatment | |

| HA1 | Case-hardened inner and outer rings |

| Suffixes - Accuracy, clearance, preload, quiet running | |

| P5 | Dimensional and running tolerances to class P5 |

| P6 | Dimensional and running tolerances to class P6 |

| P52 | P5 + C2 |

| P62 | P6 + C2 |

| P63 | P6 + C3 |

| CN | Normal radial internal clearance; only used together with an additional letter that identifies a reduced or displaced clearance range

|

| C1 | Radial internal clearance smaller than C2 |

| C2 | Radial internal clearance smaller than Normal |

| C3 | Radial internal clearance greater than Normal |

| C4 | Radial internal clearance greater than C3 |

| C5 | Radial internal clearance greater than C4 |

| CA | Matched bearing set with small axial internal clearance |

| GA | Matched bearing set with light preload |

| Suffixes - Bearing sets, matched bearings | |

| DB | Two bearings matched for mounting back-to-back |

| DF | Two bearings matched for mounting face-to-face |

| DT | Two bearings matched for mounting in tandem |

| Suffixes - Stabilization | |

| S0 | Bearing rings heat stabilized for operating temperatures ≤ 150 °C (300 °F) |

| S1 | Bearing rings heat stabilized for operating temperatures ≤ 200 °C (390 °F) |

| Suffixes - Lubrication | |

GE2 GFJ GJN HT LHT23 LT LT10 MT33 MT47 VT378 WT |

Grease suffixes |

| Suffixes - Other variants |

|

| VP311 | SKF Food Line bearing: Blue-coloured contact seal made of FDA and EC approved NBR and lubricant (GFJ) registered by NSF as category H1 |

| VQ658 | Quiet running properties |

SKF angular contact ball bearings suffix

SKF single row angular contact ball bearings

| Suffixes - Internal design |

|

| A | 30° contact angle |

| AB |

20° contact angle (inch bearing) |

| AC | 25° contact angle |

| B |

40° contact angle |

| E |

Optimized internal design |

| Suffixes - External design (seals, snap ring groove, execution, etc.) | |

| N1 |

One locating slot (notch) in one outer ring side face |

| CA | Bearing for universal matching. Two bearings arranged back-to-back or face-to-face have axial internal clearance smaller than Normal (CB). |

| CB | Bearing for universal matching. Two bearings arranged back-to-back or face-to-face have Normal axial internal clearance. |

| CC | Bearing for universal matching. Two bearings arranged back-to-back or face-to-face have axial internal clearance greater than Normal (CB). |

| G | Bearing for universal matching. Two bearings arranged back-to-back or face-to-face have axial internal clearance. |

| GA | Bearing for universal matching. Two bearings arranged back-to-back or face-to-face have light preload. |

| GB | Bearing for universal matching. Two bearings arranged back-to-back or face-to-face have moderate preload. |

| GC | Bearing for universal matching. Two bearings arranged back-to-back or face-to-face have heavy preload. |

| -2RZ |

Non-contact seal, NBR, on both sides |

| Suffixes - Cage design | |

| F | Machined steel cage, ball centred |

| J | Stamped steel cage, ball centred |

| M | Machined brass cage, ball centred; different designs are identified by a number following the M, e.g. M2 |

| MB |

Machined brass cage, inner ring centred |

| P | Glass fibre reinforced PA66 cage, ball centred |

| PH | Glass fibre reinforced PEEK cage, ball centred |

| Y | Stamped brass cage, ball centred |

| Suffixes - Materials, heat treatment (n.a.) |

| Suffixes - Accuracy, clearance, preload, quiet running | |

| P5 | Dimensional and geometrical tolerances to class P5 |

| P6 | Dimensional and geometrical tolerances to class P6 |

| Suffixes - Bearing sets, matched bearings | |

| DB | Two bearings matched for mounting back-to-back |

| DF | Two bearings matched for mounting face-to-face |

| DT | Two bearings matched for mounting in tandem |

| Suffixes - Stabilization (n.a.) |

| Suffixes - Lubrication (n.a.) |

| Suffixes - Other variants (n.a.) |

SKF double row angular contact ball bearings

| Suffixes - Internal design | |

| A |

No filling slots |

| D |

Two-piece inner ring |

| Suffixes - External design (seals, snap ring groove, execution, etc.) | |

| N | Snap ring groove in the outer ring |

| NR | Snap ring groove in the outer ring, with appropriate snap ring |

| CB | Controlled axial internal clearance |

| -2RS1 | Contact seal, NBR, on both sides |

| -2Z | Shield on both sides |

| Suffixes - Cage design | |

| – | Stamped steel cage, ball centred |

| J1 |

Stamped steel cage, ball centred (bearing with a two-piece inner ring) |

| M | Machined brass cage, ball centred |

| MA | Machined brass cage, outer ring centred. |

| TN9 | Glass fibre reinforced PA66 cage, ball centred |

| Suffixes - Materials, heat treatment (n.a.) |

| Suffixes - Accuracy, clearance, preload, quiet running | |

| P5 | Dimensional and geometrical tolerances to class P5 |

| P6 | Dimensional and geometrical tolerances to class P6 |

| P62 | P6 + C2 |

| P63 | P6 + C3 |

| P64 | P6 + C4 |

| C2 | Axial internal clearance smaller than Normal |

| C3 | Axial internal clearance greater than Normal |

| C4 | Axial internal clearance greater than C3 |

| Suffixes - Bearing sets, matched bearings (n.a.) |

| Suffixes - Stabilization (n.a.) |

| Suffixes - Lubrication | |

GE2 GWF VT113 |

Grease suffixes |

| Suffixes - Other variants (n. a.) |

SKF four-point contact ball bearings

| Suffixes - Internal design (n.a.) |

| Suffixes - External design (seals, snap ring groove, etc.) | |

| N2 | Two locating slots (notches) in one outer ring side face, 180° apart |

| Suffixes - Cage design | |

| FA | Machined steel cage, outer ring centred |

| MA | Machined brass cage, outer ring centred. |

| PHAS | Glass fibre reinforced PEEK cage, with lubrication grooves in the guiding surface, outer ring centred |

| Suffixes - Materials, heat treatment (n.a.) |

| Suffixes - Accuracy, clearance, preload, quiet running | |

| P6 | Dimensional and geometrical tolerances to class P6 |

| P62 | P6 + C2 |

| P63 | P6 + C3 |

| P64 | P6 + C4 |

| P6CNL |

P6 + CNL |

| CNL |

Axial internal clearance in the lower half of the Normal range |

| C2 | Axial internal clearance smaller than Normal |

| C2H | Axial internal clearance in the upper half of the C2 range |

| C2L | Axial internal clearance in the lower half of the C2 range |

| C3 | Axial internal clearance greater than Normal |

| C4 | Axial internal clearance greater than C3 |

| 344524 |

C2H + CNL |

| Suffixes - Bearing sets, matched bearings (n.a.) |

| Suffixes - Stabilization | |

| S1 |

Bearing rings heat stabilized for operating temperatures ≤ 200 °C (390 °F) |

| Suffixes - Lubrication (n.a.) |

| Suffixes - Other variants |

|

| 309829 | Larger balls |

SKF self-aligning ball bearings

| |

Suffixes - Internal design |

| E | Optimized internal design for increased load carrying capacity |

| Suffixes - External design (seals, snap ring groove, etc.) |

|

| -2RS1 |

Contact seal, NBR, on both sides |

| K |

Tapered bore, taper 1:12 |

| |

Suffixes - Cage design |

| M |

Machined brass cage, ball centred |

| TN9 |

Glass fibre reinforced PA66 cage, ball centred |

| |

Suffixes - Materials, heat treatment (n.a.) |

| |

Suffixes - Accuracy, clearance, preload, quiet running |

| C2 |

Radial internal clearance smaller than Normal |

| C3 |

Radial internal clearance greater than Normal |

| |

Suffixes - Bearing sets, matched bearings (n.a.) |

| Suffixes - Stabilization (n.a.) |

| Suffixes - Lubrication | |

| W64 |

Solid Oil |

| |

Suffixes - Other variants (n.a.) |

SKF thrust ball bearings suffix

| Suffixes - Cage design | |

| F | Machined steel cage, ball centred |

| M | Machined brass cage, ball centred |

| Suffixes - Accuracy, clearance, preload, quiet running | |

| P5 | Dimensional and geometrical tolerances to class P5 |

| P6 |

Dimensional and geometrical tolerances to class P6 |

SKF cylindrical roller bearing suffix

SKF single row cylindrical roller bearings

| Suffixes - Internal design | |

| A | Deviating or modified internal design |

| EC | Optimized internal design incorporating more and/or larger rollers and with modified roller end / flange contact |

| Suffixes - External design (seals, snap ring groove, etc.) | |

| K |

Tapered bore, taper 1:12 |

| N | Snap ring groove in the outer ring |

| NR | Snap ring groove in the outer ring, with associated snap ring |

| N1 | One locating slot (notch) in one outer ring side face |

| N2 | Two locating slots (notches) in one outer ring side face, 180° apart |

| Suffixes - Cage design | |

| FR |

Pin-type steel cage, pierced rollers |

| J | Stamped steel cage, roller centred |

| L |

Machined light alloy cage, roller centred |

| LA |

Machined light alloy cage, outer ring centred |

| LB |

Machined light alloy cage, inner ring centred |

| LL |

Machined light alloy cage, window-type, inner or outer ring centred (depending on bearing design) |

| M |

Machined brass cage, roller centred |

| MA(S) | Machined brass cage, outer ring centred. The S indicates a lubrication groove in the guiding surface. |

| MB | Machined brass cage, inner ring centred |

| ML | Machined brass cage, window-type, inner or outer ring centred (depending on bearing design) |

| MP | Machined brass cage, window-type, inner or outer ring centred (depending on bearing size) |

| MR | Machined brass cage, window-type, roller centred |

| P | Glass fibre reinforced PA66 cage, roller centred |

| PA | Glass fibre reinforced PA66 cage, outer ring centred |

| PH | Glass fibre reinforced PEEK cage, roller centred |

| PHA | Glass fibre reinforced PEEK cage, outer ring centred |

| Suffixes - Materials, heat treatment | |

| HA1 | Case-hardened inner and outer rings |

| HA2 | Case-hardened outer ring |

| HA3 | Case-hardened inner ring |

| HB1 |

Bainite-hardened inner and outer rings |

| HB3 | Bainite-hardened inner ring |

| HN1 | Inner and outer rings with special surface heat treatment |

| Suffixes - Accuracy, clearance, preload, quiet running | |

| CN | Normal radial internal clearance; only used together with an additional letter that identifies a reduced or displaced clearance range

|

| C2 | Radial internal clearance smaller than Normal |

| C3 | Radial internal clearance greater than Normal |

| C4 | Radial internal clearance greater than C3 |

| C5 | Radial internal clearance greater than C4 |

| Suffixes - Bearing sets, matched bearings | |

| DR | Set of two matched bearings |

| TR | Set of three matched bearings |

| QR | Set of four matched bearings |

| Suffixes - Stabilization | |

| S1 | Bearing rings heat stabilized for operating temperatures ≤ 200 °C (390 °F) |

| S2 | Bearing rings heat stabilized for operating temperatures ≤ 250 °C (480 °F) |

| Suffixes - Lubrication | |

| W33 | Annular groove and three lubrication holes in the outer ring |

| Suffixes - Other variants | |

| PEX |

SKF Explorer bearing, used only when same-sized conventional and SKF Explorer bearings are available |

| VA301 |

Bearing for railway vehicle traction motors |

| VA305 | VA301 + special inspection routines |

| VA350 | Bearing for railway axleboxes |

| VA380 | Bearing for railway axleboxes in accordance with EN 12080, class 1 |

| VA3091 | VA301 + external surfaces of the outer ring are coated with aluminium oxide |

| VC025 |

Bearing with special wear-resistant raceways for applications in heavily contaminated environments |

| VE901 | Modified internal design |

| VQ015 | Inner ring with crowned raceway for increased permissible misalignment |

SKF double row cylindrical roller bearings

| Suffixes - Internal design | |

| A, B, C | Deviating or modified internal design |

| Suffixes - External design (seals, snap ring groove, etc.) | |

| G | Helical groove in inner ring bore |

| K | Tapered bore, taper 1:12 |

| K30 | Tapered bore, taper 1:30 |

| Suffixes - Cage design | |

| F |

Machined steel cage, roller centred |

| M | Machined brass cage, roller centred |

| Suffixes - Materials, heat treatment | |

| HA1 | Case-hardened inner and outer rings |

| HA4 | Case-hardened inner and outer rings and rollers |

| HA5 | Case-hardened rollers |

| HB1 | Bainite-hardened inner and outer rings |

| Suffixes - Accuracy, clearance, preload, quiet running | |

| CN | Normal radial internal clearance; only used together with an additional letter that identifies a reduced or displaced clearance range

|

| C2 | Radial internal clearance smaller than Normal |

| C3 | Radial internal clearance greater than Normal |

| C4 | Radial internal clearance greater than C3 |

| C5 | Radial internal clearance greater than C4 |

| Suffixes - Bearing sets, matched bearings | |

| DR | Set of two matched bearings |

| TR | Set of three matched bearings |

| QR | Set of four matched bearings |

| Suffixes - Stabilization | |

| S1 | Bearing rings heat stabilized for operating temperatures ≤ 200 °C (390 °F) |

| S2 | Bearing rings heat stabilized for operating temperatures ≤ 250 °C (480 °F) |

| Suffixes - Lubrication | |

| W20 | Lubrication holes in the outer ring |

| W33(X) | Annular groove and lubrication holes in the outer ring |

SKF single row full complement cylindrical roller bearings

| Suffixes - Internal design | |

| CV | Modified internal design, full complement roller set |

| Suffixes - Cage design | |

| V | Full complement of rollers (no cage) |

| VH |

Full complement of rollers (no cage), self-retaining |

| Suffixes - Materials, heat treatment | |

| HA1 | Case-hardened inner and outer rings |

| HB1 | Bainite-hardened inner and outer rings |

| L4B | Bearing rings and rollers black oxidized |

| Suffixes - Accuracy, clearance, preload, quiet running | |

| CN | Normal radial internal clearance; only used together with an additional letter that identifies a reduced or displaced clearance range

|

| C2 | Radial internal clearance smaller than Normal |

| C3 | Radial internal clearance greater than Normal |

| C4 | Radial internal clearance greater than C3 |

| C5 | Radial internal clearance greater than C4 |

| Suffixes - Bearing sets, matched bearings | |

| DR | Set of two matched bearings |

| TR | Set of three matched bearings |

| QR | Set of four matched bearings |

SKF double row full complement cylindrical roller bearings

| Suffixes - Internal design | |

| CV | Modified internal design, full complement roller set |

| Suffixes - External design (seals, snap ring groove, etc.) | |

| ADB |

Modified internal design and seal (for NNF 50 series) |

| B | Improved seal and grease |

| DA | Modified internal design and seal (for 3194.. series) |

| -2LS | Contact seal, PUR, on both sides |

| Suffixes - Cage design | |

| V | Full complement of rollers (no cage) |

| Suffixes - Materials, heat treatment | |

| HB1 |

Bainite-hardened inner and outer rings |

| L4B | Bearing rings and rollers black oxidized |

| Suffixes - Accuracy, clearance, preload, quiet running | |

| CN | Normal radial internal clearance; only used together with an additional letter that identifies a reduced or displaced clearance range

|

| C2 | Radial internal clearance smaller than Normal |

| C3 | Radial internal clearance greater than Normal |

| C4 | Radial internal clearance greater than C3 |

| C5 | Radial internal clearance greater than C4 |

| Suffixes - Bearing sets, matched bearings | |

| DR | Set of two matched bearings |

| TR | Set of three matched bearings |

| QR | Set of four matched bearings |

SKF spherical roller bearing suffix

| |

Suffixes - Internal design |

| BC | Bearing for wind turbine main shafts with roller-guided cast iron cage |

| CA, CAC |

Retaining flanges on the inner ring, guide ring centred on the inner ring, machined brass cage |

| CC(J), CJ |

Flangeless inner ring, guide ring centred on the inner ring, two stamped steel cages |

| CCJA, EJA |

Flangeless inner ring, guide ring centred on the outer ring raceway, two stamped steel cages |

| E |

Optimized internal design for increased load carrying capacity 213, 222 and 223 series: Flangeless inner ring and two stamped steel cages. Annular groove and three lubrication holes in the outer ring. d ≤ 65 mm: Guide ring centred on the inner ring d > 65 mm: Guide ring centred on the cage |

| Suffixes - External design (seals, snap ring groove etc.) |

|

| -CS, -2CS |

Contact seal, NBR, on one or both sides |

| -CS2, -2CS2 |

Contact seal, FKM, on one or both sides |

| -CS5, -2CS5 |

Contact seal, HNBR, on one or both sides |

| -RS, -2RS |

Contact seal, NBR, on one or both sides |

| -RS5, -2RS5 |

Contact seal, HNBR, on one or both sides |

| K |

Tapered bore, taper 1:12 |

| K30 |

Tapered bore, taper 1:30 |

| |

Suffixes - Cage design |

| F |

Machined steel cage, inner ring centred |

| FA |

Machined steel cage, outer ring centred |

| J |

Stamped steel cage, inner ring centred |

| JA |

Stamped steel cage, outer ring centred |

| MA |

Machined brass cage, outer ring centred |

| |

Suffixes - Materials, heat treatment |

| 235220 |

Case-hardened inner ring with a helical groove in the bore |

| HA3 |

Case-hardened inner ring |

| Suffixes -Accuracy, clearance, preload, quiet running |

|

| C08 |

Running accuracy to P5 tolerance class |

| C083 |

C08 + C3 |

| C084 |

C08 + C4 |

| C2 |

Radial internal clearance smaller than Normal |

| C3 |

Radial internal clearance greater than Normal |

| C4 |

Radial internal clearance greater than C3 |

| C5 |

Radial internal clearance greater than C4 |

| P5 |

Dimensional and running accuracy to P5 tolerance class |

| P6 |

Dimensional and running accuracy to P6 tolerance class |

| P62 |

P6 + C2 |

| |

Suffixes - Lubrication |

| GEM9 |

Filled to 70 – 100% with SKF LGHB 2 grease |

| GLE |

Filled to 25 – 45% with SKF LGWM 2 grease |

| VT143 |

Filled to 25 – 45% with SKF LGEP 2 grease |

| VT143B |

Filled to 45 – 60% with SKF LGEP 2 grease |

| VT143C |

Filled to 70 – 100% with SKF LGEP 2 grease |

| W64 |

Solid Oil |

| W |

Without annular groove and lubrication holes in the outer ring |

| W20 |

Three lubrication holes in the outer ring |

| W26 |

Six lubrication holes in the inner ring |

| W33 |

Annular groove and three lubrication holes in the outer ring |

| W33X |

Annular groove and six lubrication holes in the outer ring |

| W77 |

Plugged W33 lubrication holes |

| W513 |

W26 + W33 |

| |

Suffixes - Other variants |

| R505 | Bearing for railway axleboxes |

| VA405 | Bearing for vibratory applications, surface-hardened stamped steel cages |

| VA406 | Same as VA405, but PTFE coated cylindrical inner ring bore |

| VA991 | Bearing for high-speed applications |

| VE552(E) | Outer ring with three equally-spaced threaded holes in one side face to accommodate lifting tackle. The E indicates that appropriate eye bolts are supplied with the bearing. |

| VE553(E) |

Same as VE552(E), but threaded holes in both side faces |

| VG114 |

Surface-hardened stamped steel cages |

| VQ424 |

Running accuracy better than C08 |

SKF CARB toroidal roller bearings suffix codes

| Suffixes - External design (seals, snap ring groove etc.) | |

| -CS5, -2CS5 |

Contact seal, HNBR, on one or both sides |

| -NS, -2NS | Contact seal, NBR, on one or both sides |

| K |

Tapered bore, taper 1:12 |

| K30 |

Tapered bore, taper 1:30 |

| |

Suffixes - Cage design |

| – | Stamped steel cage, roller centred |

| M | Machined brass cage, roller centred |

| MB, MB1 | Machined brass cage, inner ring centred |

| TN9 | Glass fibre reinforced PA46 cage, roller centred |

| V | Full complement of rollers (no cage) |

| |

Suffixes - Materials, heat treatment |

| HA3 | Case-hardened inner ring |

| |

Suffixes - Accuracy, clearance, preload, quiet running |

| C08 | Geometrical tolerances to class P5 |

| C2 | Radial internal clearance smaller than Normal |

| C3 |

Radial internal clearance greater than Normal |

| C4 |

Radial internal clearance greater than C3 |

| C5 |

Radial internal clearance greater than C4 |

| Suffixes - Stabilization |

|

| S3 |

Bearing rings heat stabilized for operating temperatures ≤ 300 °C (570 °F) |

| Suffixes - Lubrication |

|

| GEM9 | Filled to 70 – 100% with SKF LGHB 2 grease |

| |

Suffixes - Other variants |

| VE240 | Bearing with shorter rollers |

| VG114 | Surface-hardened stamped steel cage |

| VM118 |

Full complement bearing without retaining ring |

| VT143 |

Filled to 25 – 45% with SKF LGEP 2 grease |

SKF cylindrical roller thrust bearings suffix codes

| |

Suffixes - Cage design |

| M |

Machined brass cage |

| TN |

Glass fibre reinforced PA66 cage |

| |

Suffixes - Materials, heat treatment |

| HA1 | Case-hardened shaft and housing washers |

| HB1 |

Bainite-hardened shaft and housing washers |

| |

Suffixes - Accuracy, clearance, preload, quiet running |

| P5 |

Dimensional and geometrical tolerances to class P5 |

SKF spherical roller thrust bearings suffix codes

| Suffixes - Internal design | |

| E | Optimized internal design |

| Suffixes - External design (seals, snap ring groove, etc.) | |

| N1 | One locating slot in the housing washer |

| N2 | Two locating slots in the housing washer, 180° apart |

| |

Suffixes - Cage design |

| – |

|

| F | Machined steel cage, shaft washer centred |

| F3 | Machined spheroidal cast iron cage, shaft washer centred |

| M | Machined brass cage, shaft washer centred |

| |

Suffixes - Other variants |

| VE447(E) | Shaft washer with three equally-spaced threaded holes to accommodate hoisting tackle. The E indicates that appropriate eye bolts are supplied with the bearing. |

| VE710(E) | Housing washer with three equally-spaced threaded holes to accommodate hoisting tackle. The E indicates that appropriate eye bolts are supplied with the bearing. |

| VU029 | Shaft washer modified for applications with small axial clearance |