Timken inch series needle roller and cage radial assemblies are available in a variety of sizes and designs. This catalog includes the most popular standard designs.

There are two primary constructions of inch series needle roller and cage assemblies. The WJ assemblies generally employ larger diameter needle rollers whereas the WJC assemblies normally employ smaller diameter needle rollers.

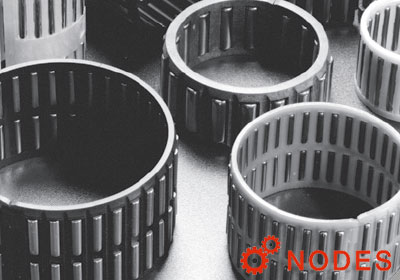

TIMKEN needle roller and cage radial assemblies have a steel cage which provides both inward and outward retention for the needle rollers. The designs provide maximum cage strength consistent with the inherent high load ratings of needle roller bearings.

INCHES SERIES

Accurate guidance of TIMKEN needle rollers by the cage bars allows for operation at high speeds. Needle roller and cage assemblies have either one or two rows of needle rollers.

Also available (on request) are needle roller and cage assemblies using molded, one piece glass reinforced engineered polymer cages. These operate well at temperatures up to 250° F (120° C) over extended periods. However, care should be exercised when bearings are lubricated with oils containing additives as service life may be reduced if the operating temperature exceeds 212° F (100° C). At such high temperatures oil can deteriorate with time and it is suggested that oil change intervals are observed.

TIMKEN needle rollers with relieved ends used in these assemblies are made of high carbon chrome steel, through-hardened, ground and lapped to close tolerances for diameter and roundness. See the engineering section of this catalog for further discussion of relieved end rollers.

Timken inch series needle roller and cage radial assemblies dimensional accuracy

The nominal inch assemblies, WJ and WJC, contain needle rollers manufactured to only one diameter grade. Within any one assembly, the needle rollers have a total diameter tolerance of .0001 inch.

The limit to precision of the radial clearance of mounted needle roller and cage assemblies is the capability of the user to hold close tolerances on the inner and outer raceways.

The tolerance of the overall width of these assemblies is given on the tabular pages of this section.