Bearing life is essentially the length of time a NSK bearing can be expected to perform as required in predefi ned operating conditions. It is based primarily on the probable number of rotations a bearing can complete before it starts showing symptoms of fatigue, such as spalling or cracking due to stress.

What determines a NSK bearing’s service life?

In addition to natural wear and tear, NSK bearings can fail (prematurely) due to other factors such as extreme temperatures, cracks, lack of lubrication, or damage to the seals or cage. Bearing damage of this kind is often the result of choosing the wrong bearings, inaccuracies in the design of the surrounding components, incorrect installation or insuffi cient maintenance.

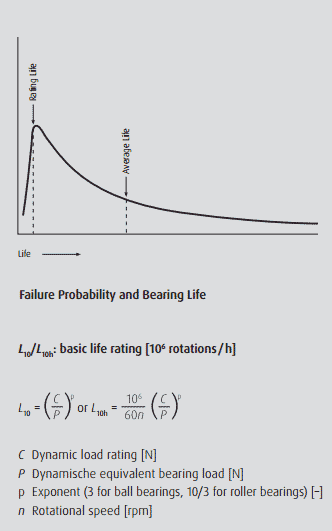

Basic fatigue life rating L10

A NSK bearing’s basic fatigue life rating is calculated using the number of rotations which 90% of all bearings in a specific group achieve or exceed a calculated time without failure (probability of failure: 10%).

A standardised formula – also known as the catalogue method (ISO 281) – is the conventional means of calculating a bearing’s life. The parameters are bearing load, rotational speed, dynamic load rating and bearing type. The result is the bearing fatigue life L10 or L10h.

- The Dynamic load rating (basic load rating) is defined as the constant load applied on bearings with stationary outer rings that the inner rings can endure for a rating life of one million revolutions (106 rev). The basic load rating of radial bearings is defi ned as a central radial load of constant direction and magnitude, while the basic load rating of thrust bearings is defined as an axial load of constant magnitude in the same direction as the central axis. The load ratings are listed under Cr for radial bearings and Ca for thrust bearings in the dimension tables.

-

The dynamic equivalent load P is defined as a mathematical radial load for radial bearings or axial load for axial bearings of a constant magnitude and direction which has the same effect on bearing life as the forces actually acting on the component. In the case of combined or constant loads, the value of P is

calculated using the following formula: P = X • Fr + Y • Fa

Apart from Thrust Spherical Roller Bearing: P = Fa + 1,2 • Fr

Adjusting NSK bearings to the operating temperature

If NSK bearings are used at high operating temperatures, the bearing steel loses hardness. The nominal speed should therefore be adjusted for higher temperatures with the aid of this equation:

Ct = ft * C

Ct: Basic load rating after temperature correction (N)

ft: Temperature factor

C Basic load rating before temperature adjustment (N)

| Temperature factor ft | |||||

|---|---|---|---|---|---|

| Bearing temperature °C | 125 | 150 | 175 | 200 | 250 |

| Temperature factor ft | 1.00 | 1.00 | 0.95 | 0.90 | 0.75 |

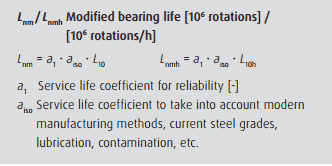

Modified bearing life

Although nominal NSK bearing life is sufficient as a criterion, it is desirable for many applications to calculate service life more precisely, taking lubrication and contamination into account.

It has also been established that the very good grades of steel and quality of manufacturing now available make it possible for bearings to last longer than the nominal life L10 suggests if conditions are favourable and the contact load does not exceed a certain level. However, unfavourable operating conditions may shorten the service life. To take this into account, the factors a1 and aiso have been defined, resulting in the modified bearing life Lnm.

| Reliability Factor a1 | ||||||

|---|---|---|---|---|---|---|

| Reliability (%) | 90 | 95 | 96 | 97 | 98 | 99 |

| a1 | 1.00 | 0.64 | 0.55 | 0.47 | 0.37 | 0.25 |