When selecting SKF bearings for any purpose, ultimately you want to be certain of achieving the required level of equipment performance, and robustness, at the lowest possible cost. There are key factors you must consider when selecting SKF bearings for an application. For helping you evaluate these key factors, we provide recommended SKF bearing selection, as well as supporting information.

SKF general bearing knowledge:

- SKF bearing designation

- SKF bearing prefixes

- SKF bearings cross reference

- Shaft and housing tolerances

SKF bearing selection

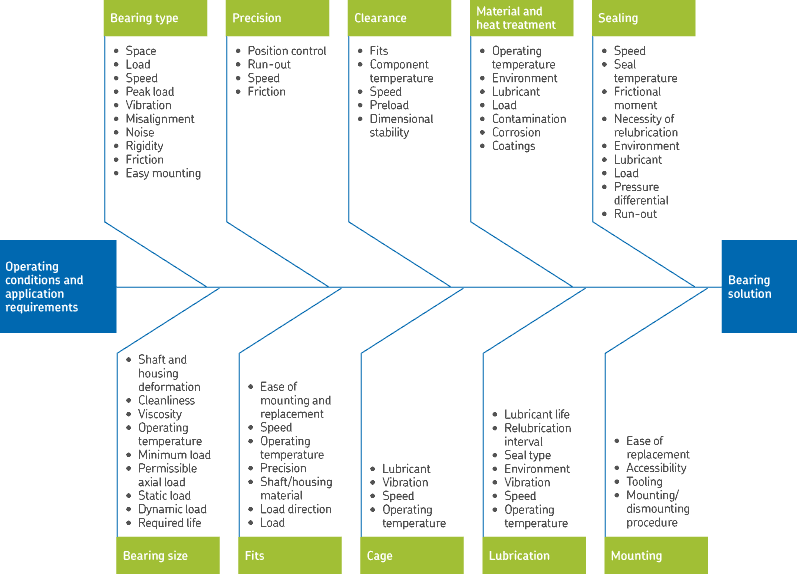

In addition to the SKF bearing rating life, there are key factors you must consider when putting together the SKF bearing specifications for an application, including:

- lubricant and supply method

- shaft and housing fits

- bearing clearance class

- cage material and guidance

- dimensional stability

- precision requirements

- bearing sealing

- mounting method and maintenance

To help evaluate there key factors, we recommend following this selection process:

The SKF bearing selection provides a straight forward step-by-step approach that shows the general relationship between each step.

1, Performance and operating conditions.

The first step of SKF bearing selection is to understand and document:

- the required performance

- the operating conditions and assumptions of them

- any other application prerequisites

The drawing shows the relationship between principal operating conditions, application requirements and various aspects of a bearing arrangement’s design. The lists are not comprehensive and you may have to consider other factors and interrelationships, such as cost and availability, when striving to obtain a robust and cost-effective solution.

2, SKF bearing type and arrangement

Each SKF bearing type has characteristic properties that make it more or less suitable for use in a given application. This section provides information on what to consider when selecting a bearing arrangement and the types of bearing to use with it. It also provides guidelines on choosing bearing types to satisfy specific demands of an application, such as accommodating available space, loads, misalignment, and more.

- Arrangement and SKF bearing types

- Selection criteria

3, SKF bearing size

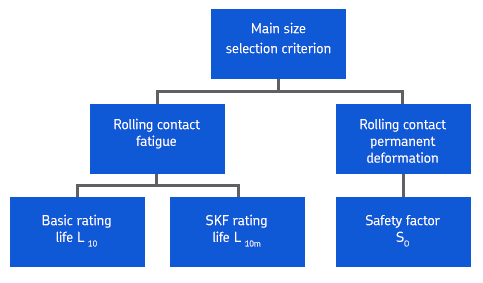

The size of a bearing must be sufficient to ensure that it is strong enough to deliver the required/expected life under defined operating conditions. the two main criteria that can be used for determining appropriate bearing size are:

- size selection based on rating life

- size selection based on static load

Main selection criteria for bearing size and related bearing ratings and safety factor

The above diagram shows these selection criteria and the related bearing ratings and static safety factor, which are described in detail in the relevant sub-sections. Which selection criteria you should use depends on the operating conditions of the bearing:

- For applications where bearings are running in typical operating conditions – i.e. normal speeds, good lubrication conditions and not highly or peak loaded. – use Size selection based on rating life.

- For applications where bearings are running under very low speeds or which are used under stationary conditions, very bad lubrication conditions or where occasional peak loads occur, use Size selection based on static load.

4, SKF lubrication

SKF rolling bearings must be adequately lubricated to operate reliably. The lubricant is required to reduce friction, inhibit wear, protect the bearing surfaces against corrosion and may also be needed to provide cooling. This section describes:

- how to select between grease or oil

- how to select a suitable grease

- how to select a suitable oil

How lubrication relates to other selection criteria

Lubrication selection and lubricant properties greatly influence the operating temperature, which in turn influences:

- whether you should use grease or oil

- the relubrication interval required for grease

- whether oil lubrication is necessary, because circulating oil can be used to remove heat

- the lubrication condition – the viscosity ratio, κ, which influences the bearing size selection based on SKF rating life

5, SKF operating temperature and speed

The relationships between the temperature and power loss of components within an application is complex and these factors, in turn, have interdependencies with many others such as bearing sizes, loads and lubrication conditions.

They influence many performance characteristics of an application and its parts, and do so in various ways depending on the operational state, such as at startup or in normal operation, when steady-state conditions have been reached.

6, SKF bearing interfaces

7, SKF bearing execution

8, Sealing, mounting and dismounting