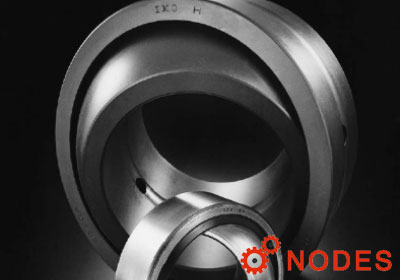

IKO Spherical Bushings are self-aligning spherical plain bushings that have inner and outer rings with spherical sliding surfaces, and can take a large radial load and a bi-directional axial load at the same time. There are many types of Spherical Bushings, but they are basically divided into steel-on-steel types and maintenance-free types according to the kind of sliding surfaces.

IKO Steel-on-steel Spherical Plain bearings have inner and outer rings of high carbon chromium bearing steel, of which sliding surfaces are phosphate-treated and then dry-coated with molybdenum disulfide (MoS2). They can, therefore, operate with low torque, and have excellent wear resistance and large load capacity. They are especially suitable for applications where there are alternate loads and shock loads. They have wide applications mainly in industrial and construction machinery.

IKO Maintenance-free Spherical Bushings consist of an outer ring which has a special PTFE liner reinforced with copper alloy meshes on the sliding surface, and a spherical inner ring of which sliding surface has a hard chromium plating. Creep deformation due to compressive load is small, and wear resistance is superior. Thus, they are maintenance-free and can be used for extended periods of time without re-lubrication. They are especially suitable in cases where fixed directional loads are applied and are used mainly in food processing machines and construction machinery and in other applications in which the use of oil is undesirable or lubrication is not possible.

IKO Spherical Bushings Types

Steel-on-steel Spherical Bushings SB

These IKO bushings have an outer ring split into halves. The split outer ring and the inner ring are held together by a snap ring placed in the groove around the outer periphery of the outer ring.

Steel-on-steel Spherical Bushings SB...A

These bushings have an outer ring split only at one position, and therefore, the outer and inner rings will not separate. Handling before mounting and mounting to the housing are simple. The boundary dimensions are the same as those of the SB type.Therefore, SB and SB... A types are dimensionally interchangeable, but the radial internal clearances of the SB...A type are smaller than those of the SB type.

Steel-on-steel Spherical Bushings GE...E, GE...ES

The dimension series of these types conform to ISO standards and they can be used internationally. The outer ring is split at one position. The GE ..E and GE .. ES types are available. These are classified by bushing size.

The GE...ES type can be provided with seals, which are double-lip type polyurethane seals effective for prevention against grease leakage and dust penetration. The sealed type is indicated by the suffix "-2RS" at the end of the identification number.

Steel-on-steel Spherical Bushings GE...G, GE...GS

As compared with the GE...E and GE...ES types, these bushings have larger load capacities and larger permissible tilting angles. The dimension series also conform to ISO standards, and they can be used internationally. The outer ring is split at one position. The GE...G and GE...GS types are available. They are classified by bushing size.

The GE...GS type can be provided with seals, which are double-lip type polyurethane seals effective for prevention against grease leakage and dust penetration.

Steel-on-steel Spherical Bushings SBB

These are inch series IKO bushings. The outer ring is split at one position. These IKO bushings can be provided with seals, which are double-lip type polyurethane seals effective for prevention against grease leakage and dust penetration.

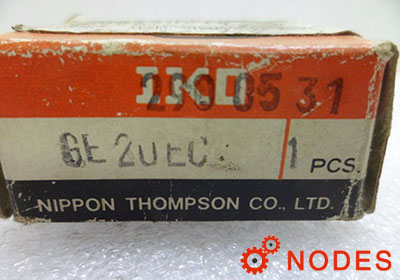

Maintenance-free Spherical Bushings GE...EC

These bushings have the same boundary dimensions as the GE .. ES type and can be used internationally. A special PTFE liner reinforced with copper alloy meshes is used on the sliding surface. Therefore, creep deformation due to compressive loads is small, and wear resistance is superior. These bushings are used as maintenance-free bushings.

These IKO bushings can be provided with synthetic resin seals which are effective in preventing dust penetration. They are indicated by the suffix "-2RS" at the end of the identification number.

related articles

Related numbers

IKO GE20EC spherical bushings

20mm x 35mm x 16mm

IKO GE45EC-2RS spherical bushings

45mm x 68mm x 32mm

IKO GE40ES spherical bushings

40mm x 62mm x 28mm

IKO GE45ES spherical bushings

45mm x 68mm x 32mm

IKO GE50ES spherical bushings

50mm x 75mm x 35mm

IKO GE70ES spherical bushings

70mm x 105mm x 49mm

IKO GE30ES-2RS spherical bushings

30mm x 47mm x 22mm