Where INA needle roller and cage assemblies are to be used, the housing bore and the shaft raceway must be hardened and ground. The surface hardness of the raceways must be 670 HV + 170 HV, the hardening depth CHD or SHD must be sufficiently large. Design of raceways, see table below

|

Shaft - diameter |

Bore - tolerance |

Shaft tolerance | Roughness | Roundness | Parallelism | |||

|---|---|---|---|---|---|---|---|---|

|

Nominal dimension mm |

Bearing clearance | |||||||

| over | incl. | Small | Normal | Large | max. | max. | max. | |

| - | 80 | G6 | j5 | h5 | g6 | Ra0,2 (Rz1) | IT3 | IT3 |

| H6 | h5 | g5 | f6 | |||||

| 80 | 120 | G6 | h5 | g5 | f6 | Ra0,3(Rz1,6) | ||

| 120 | - | G6 | h5 | g5 | f6 | Ra0,4(Rz2,5) | ||

| H6 | - | f5 | e6 | |||||

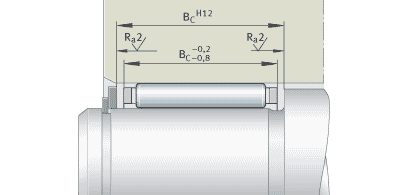

The raceway width must be at least equal to the cage width Bc (Bc is produced with a minus (–) tolerance); values for Bc, see dimension tables. The distance between the axial limit surfaces should therefore be toleranced to H12

The axial running surfaces for the needle roller and cage assemblies must be precision machined (Ra2 recommended) and resistant to wear.

Raceway width and axial running surfaces