SKF bearing internal clearance is defined as the total distance through which one bearing ring can be moved relative to the other in the radial direction (radial internal clearance) or in the axial direction (axial internal clearance).

In almost all applications, the initial clearance in a SKF bearing is greater than its operating clearance. The difference is mainly caused by two effects:

- Bearings are typically mounted with an interference fit on the shaft or in the housing. The expansion of the inner ring or the compression of the outer ring reduces the internal clearance.

- Bearings generate heat in operation. Differential thermal expansion of the bearing and mating components influences the internal clearance.

Sufficient internal clearance in a bearing during operation is important. Preload (clearance below zero) is possible for certain SKF bearing types.

To enable selection of the appropriate initial internal clearance to achieve the desired operational internal clearance, SKF bearings are available in different clearance classes. ISO has established five clearance classes for many bearing types. SKF uses designation suffixes to indicate when the bearing internal clearance differs from Normal. Please refer to the SKF bearing clearance chart below.

| ISO clearance class | SKF designation suffix | Internal clearance |

|---|---|---|

| - | C1 | Smaller than C2 |

| Group 2 | C2 | Smaller than Normal |

| Group N | - | Normal |

| Group 3 | C3 | Greater than Normal |

| Group 4 | C4 | Greater than C3 |

| Group 5 | C5 | Greater than C4 |

How to select initial internal clearance for SKF bearings

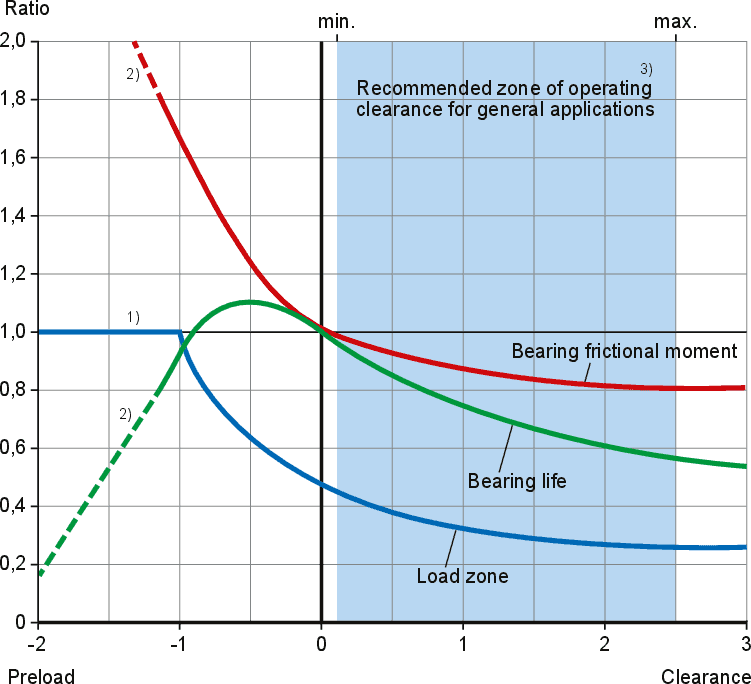

The operating clearance or preload in a SKF bearing influences, among other things, the friction, load zone size and fatigue life of a SKF bearing.

Operational clearance or preload versus main operational criteria

1) A ratio of 1 means that all rolling elements are loaded.

2) The dotted line indicates potentially unstable working conditions.

3) Limits of range are determined by initial clearance, fit and temperature effects.

The diagram above shows the relationship between these parameters. The diagram is generalized and based on rolling bearings under radial load. For general applications, the operating clearance range should be within the recommended zone.

You must ensure that the bearing has a minimum initial internal clearance of a size that, when it is reduced by the effects of mounting and other influences, is equal to or greater than the required minimum operating clearance.

Range of initial internal clearance

SKF bearing types for adjusted bearing arrangements – such as angular contact ball bearings, tapered roller bearings or spherical roller thrust bearings – have their internal clearance set during mounting. The internal clearance of such an arrangement, even though set by adjustment during mounting, will nevertheless have a range.

For other bearing types, the initial internal clearance is determined during their manufacture. ISO has defined five clearance classes for specifying the degree of initial internal clearance in a bearing. Each clearance class represents a range of values. The size of the ranges varies depending on bearing type and size. Clearance class details are listed in relevant product sections.

Initial clearances greater than Normal, such as C3 or even C4 clearance classes, are very common today. This is because modern SKF bearings take higher loads and require tighter interference fits, and typical operating conditions are different, compared to when the clearance classes were defined.

For universally SKF matchable single row angular contact ball bearings and matched tapered roller bearings, double row angular contact ball bearings and four-point contact ball bearings, values for the axial internal clearance are given instead of radial internal clearance, because the axial clearance is of greater practical importance for these bearing types. Radial internal clearance is related to axial internal clearance and that relationship is determined by the bearing type and its internal geometry.

SKF clearance reduction caused by interference fits

An interference fit causes clearance reduction because inner rings are expanded and outer rings are compressed. The reduction equals the effective interference fit multiplied by a reduction factor using

Δrfit = Δ1 f1 + Δ2 f2

where

| Δrfit | clearance reduction caused by the fit [μm] |

| f1 | reduction factor for the inner ring |

| f2 | reduction factor for the outer ring |

| Δ1 | effective interference between the inner ring and shaft [μm] |

| Δ2 | effective interference between the outer ring and housing [μm] |

SKF clearance reduction casued by temperature difference between shaft, bearing rings and housing

The temperature behaviour of an application can create a difference in temperature between a SKF bearing inner ring and outer ring, which changes the mounted bearing clearance/preload. For a steel shaft and steel or cast iron housing, the change can be estimated using

Δrtemp = 0,012 ΔT dm

where

| Δrtemp | clearance reduction caused by temperature difference [μm] |

| ΔT | temperature difference between inner and outer ring [°C] |

| dm |

the bearing mean diameter [mm] = (d + D)/2 |