INA tape tension pulleys

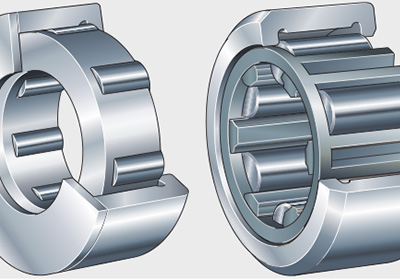

INA tape tension pulleys BSR are high precision ball bearings with one or two rows of rolling elements. The outer ring half-cups are made from pressed steel. Due to their low mass moment of inertia, the spindles can be rapidly accelerated up to operating speed. Due to the use of gap seals, friction is low.

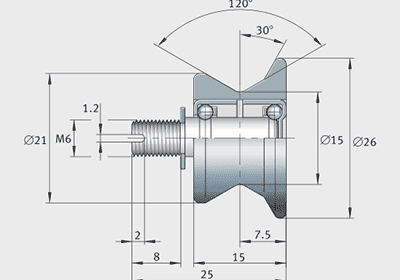

The pulleys are matched to the normal belt dimensions and mounting conditions.

INA pulley bearings

INA pulley bearings RLBSR..-100 for textile bearings are high precision ball bearings with one or two rows of rolling elements. Due to their low mass moment of inertia, the spindles can be rapidly accelerated up to operating speed. Due to the use of gap seals, friction is low.

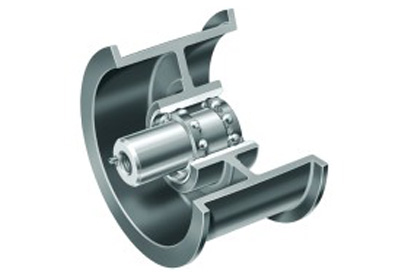

Pulley bearings RLBSR..-100 are also suitable for the design of tape tension pulleys that require special tyres.

INA tape tension pulleys and pulley bearings application: Tape tension pulleys are used to guide and tension the drive belts in textile machinery, especially in spinning, texturing and twisting machines.

Sealing: On the pin side, the pulleys have a gap seal. On the outer side, the pulleys are sealed by a spring diaphragm.The lubrication hole is located at the centre of the diaphragm.

Lubrication: Tape tension pulleys and pulley bearings have an initial greasing of grease K3K–30 to DIN 51825. This grease is a lithium soap grease with a mineral oil base and a base oil viscosity of ISO-VG100.

Relubrication: The grease used for relubrication should be the same as that used for initial greasing. The pulley bearings are relubricated through a lubrication hole in the fixing screw or in the end washer. For this lubrication hole, a metering gun with a tapered nozzle should be used

Rotate the INA bearing by hand in order to ensure uniform distribution of the grease. The relubrication quantity is as follows:

- 0,5 g to 0,8 g for single row bearings

- 1 g to 1,5 g for double row bearings.

The guide values for the relubrication intervals in operating hours are as follows:

- approx. 30000 h if little fly is present

- approx. 12000 h if considerable fly is present.