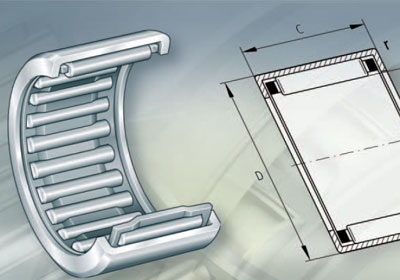

INA drawn cup needle roller bearings with open ends and with closed end are complete units comprising thin-walled, drawn cup outer rings and needle roller and cage assemblies. Drawn cup needle roller bearings are also available in a full complement design. The majority of the bearings are of a single row design.

Raceway for bearings without inner ring

Where bearings without an inner ring are to be used, the rolling element raceway on the shaft must be hardened and ground. The surface hardness must be at least 670 HV, the hardening depth CHD or Rht must be sufficiently large.

In order to utilise the load carrying capacity of the bearings to the full, rigid support must be provided for the thin-walled outer ring.

Note the recommended bore tolerance according to the table for the shaft raceway/housing bore.

INA drawn cup needle roller bearings

Tolerances for shaft raceway/housing bore

| Housing material |

Shaft tolerance for bearings without inner ring |

Bore tolerance |

|---|---|---|

| Steel or cast iron | h6 | N6 |

| Light metal Al | R6 | |

| Light metal Mg | S6 |

Surface for shaft raceway/housing bore

| Surface quality |

Shaft raceway for bearings without inner ring |

Housing bore |

|---|---|---|

| Roughness max. | Ra0,2 (Rz1) | Ra0,8 (Rz4) |

| Roundness | IT 3 | IT 5/2 |

| Parallelism | IT 3 | IT 5/2 |

Static load safety factor

S0 = C0r / P0

S0: Static load safety factor

C0r: Basic static load rating according to dimension tables

P0: Equivalent static bearing load.

In order to achieve sufficiently smooth running, a static load safety factor S0 >= 3 is necessary.

Speeds

The speeds in the dimension tables are valid for oil lubrication. If grease lubrication is used, 60% of the stated value is permissible.

Radial location

INA drawn cup needle roller bearings are pressed into the housing bore and require no further axial location.

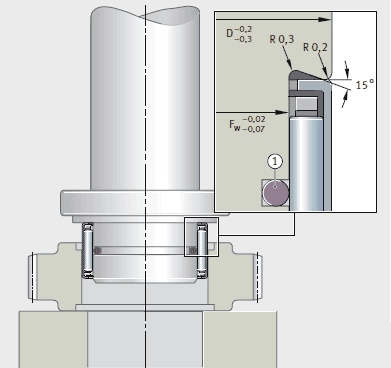

Installation with fitting mandrel

Installation using a fitting mandrel

(1)Round section seal

The bearings should be installed using a special fitting mandrel. The shoulder of the fitting mandrel should rest on the bearing end face marked with the designation.

A round section seal (1) should be used to retain the bearing. The length and oversize of the round section seal must be matched by the customer to the dimensions and mass of the bearing.

Before installation, the bearings should be lubricated with grease, if grease lubrication is to be used.

Do not tilt drawn cup bearings during fitting. Forces occurring during the fitting process are dependent on several variables. The fitting situation should be arranged so that the bearing rib on the end face is not deformed.