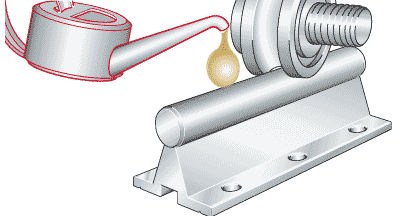

The guideway raceways must be lubricated (even before first use). Lubrication can be carried out by means of lubrication and wiper units.

These units are already integrated in the compact carriage LFKL. For carriages LFL and LFCL, the lubrication and wiper unit AB is available as an accessory.

The guideway raceway is lubricated by an oil-soaked felt insert. Oil can be fed to the felt inserts via lubrication nipples in the end faces. At delivery, the felt inserts are already soaked with oil (H1 approval for the food industry), where relubrication is to be carried out an oil of vicosity 460 mm2/s is recommended.

Lubrication intervals: The lubrication intervals for guideway raceways are dependent on the environmental influences. The cleaner the environment, the smaller the quantity of lubricant required. The time and quantity can only be determined precisely under operating conditions since it is not possible to calculate all the influences in advance.

A sufficiently long observation period must be allowed.

Lubrication of INA track rollers

At delivery, track rollers LFR have an initial greasing of a high quality lithium soap grease.

From LFR5204-16, the inner ring has a relubrication hole. The smaller track roller diameters are lubricated for life.

Further information can be found in Catalogue HR1, Rolling Bearings, in the section Lubrication.