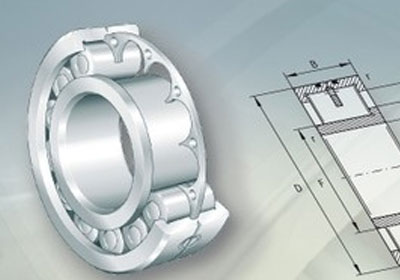

INA low friction cylindrical roller bearings LSL and ZSL are of a single row, self-retaining design and correspond to dimension series 23. The bearings have solid outer rings with two ribs, the inner rings are designed with one rib. The inner ring is removable and thus allows easier mounting of the bearings. The disc cages or spacers prevent the cylindrical rollers from coming into contact with each other during rolling.

Cylindrical roller bearings NJ23..-E and spherical roller bearings 223..-E1 have the same design envelope as LSL1923 and ZSL1923.

X-life

Numerous sizes are supplied in the X-life grade. These bearings are indicated in the INA bearings dimension tables.

Semi-locating bearings

INA cylindrical roller bearings LSL1923 and ZSL1923 are semi-locating bearings and can support not only high radial forces but also large axial forces in one direction. They act as non-locating bearings in the opposite direction.

Since they have a larger number of rolling elements and larger rolling elements, LSL and ZSL INA bearings have higher radial and axial load carrying capacity than all comparable cylindrical roller bearing designs with a solid cage. They can withstand high shock loads and vibrations, support large centrifugal forces and allow accelerations up to 500 m/s2.

Due to the low frictional torque across the entire speed range and the low heat generation, the bearings have the highest limiting speeds of all cylindrical roller bearings. In addition, the optimum heat dissipation ensures thermally stable conditions in the bearing.

In cylindrical roller bearings LSL1923, an externally-guided flat brass disc cage prevents the cylindrical rollers from coming into contact with each other during rolling.

The cage has pockets to accommodate the rolling elements. The rolling elements are guided between the ribs on the outer ring. Due to its low mass, the cage is subjected to only minimal strain under acceleration. It therefore fulfils ideally its role as an element separating the rolling elements and supporting the inertia forces.

Lubricant is exchanged via axial through holes. Good oil flow through the axially open bearing is supported by the axial holes. The outer ring is axially split and held together by fasteners.