The factors that are most important to consider when selecting the material and surface finish of the counter surface on which the SKF bushing slides are the load conditions such as load, angle of oscillation, type of movement, and environmental influences.

Where there is a risk of corrosion, the counter face should be sufficiently resistant. Corrosion scars in the counter surface and for example abrasive particulate contamination as a by-product of corrosion increase the surface roughness accelerate wear. In this cases, the use of stainless steel or a surface treatment such as hard chromium, nickel plating or electrolytic oxidation should be considered.

This page provides SKF bushing type specific recommendations on the following design considerations, as far as applicable:

- shaft and housing tolerances

- shaft roughness and hardness

- material and surface finish of counter surfaces

- design of associated components

- sealing solutions

SKF solid bronze bushings

| Shaft tolerance | e7 to e8 |

| Housing tolerance | H7 |

| Shaft roughness | Ra ≤ 1,0 µm |

| Shaft hardness | 165 to 400 HB |

SKF sintered bronze bushings

| Shaft tolerance | f7 to f8 |

| Housing tolerance | H7 |

| Shaft roughness | Ra: 0,2 to 0,8 µm |

| Shaft hardness | 200 to 300 HB |

SKF wrapped bronze bushings

| Shaft tolerance | e7 to f8 |

| Housing tolerance | H7 |

| Shaft roughness | Ra: 0,4 to 0,8 µm |

| Shaft hardness | 150 to 400 HB |

SKF PTFE and POM composite bushings

| Shaft tolerances |

Metric PTFE composite bushings (table):

Metric POM composite bushings: h8 Inch PTFE composite bushings Inch POM composite bushings |

| Housing tolerances1) |

Metric PTFE composite bushings:

Metric POM composite bushings: H7 Inch PTFE composite bushings Inch POM composite bushings |

| Shaft roughness |

PTFE composite bushings: Ra ≤ 0,4 µm; Rz ≤ 3,0 µm POM composite bushings: Ra ≤ 0,8 µm; Rz ≤ 6,0 µm |

| Shaft hardness |

PTFE composite bushings: 300 to 600 HB POM composite bushings: 150 to 600 HB |

1)The recommended tolerances and guideline limits quoted in the tables are valid for steel and cast iron housings. Where light alloy housings are used, a greater degree of interference may be required because of the different thermal expansion characteristics of the housing and the bushing. There is otherwise a risk that the greater thermal expansion of the housing would no longer provide radial location for the bushing and that the operating clearance would be too large. If it is not possible to adopt a greater interference fit, it might be possible to use an adhesive to retain the bushing. In special cases it may be necessary, by selecting a suitable tolerance for the shaft, to prevent an inadmissible increase in operating clearance.

Material and surface finish of counter surfaces

For PTFE composite and POM composite plain bearing arrangements, soft carbon steels with a ground surface are usually adequate for the counter surface.

For more demanding applications, SKF recommends hardened counter surfaces. These should have a surface hardness of at least 500 HB (50 HRC). Alternatively, hard chromium, nickel plating or some other form of surface treatment can be considered. In all cases Ra should not be greater than 0,3 μm (Rz ≤ 2 μm). The better the surface finish, the better the running and wear properties.

SKF PTFE polyamide bushings

| Shaft tolerance | h8 to h9 |

| Housing tolerance | H7 |

| Shaft roughness | Ra ≤ 0,8 µm |

| Shaft hardness | 100 to 300 HB |

SKF filament wound bushings

| Shaft tolerances |

h8

|

| Housing tolerance |

H7

|

| Shaft roughness |

Ra: 0,2 to 0,4 µm |

| Shaft hardness | ≥ 490 HB (≥ 50 HRC) |

Material and surface finish of counter surfaces

SKF generally recommends using hardened counter surfaces for filament wound bushings.

Profiles having sharp edges, for example high Rr values, result in heavy wear even if the Ra values are within the recommended range. Although greater surface roughness might be acceptable for oscillating movement, heavy wear occurs when the bushings rotate or perform linear movements.

To fully exploit the potential service life of the bushing it may be necessary to optimise the counter surface. The best results have been obtained with polished, hard chromium plated as well as with nitrided surfaces.

Whether an adequate service life can be obtained if the condition of the counter surface is outside the recommendations has to be checked from case to case.

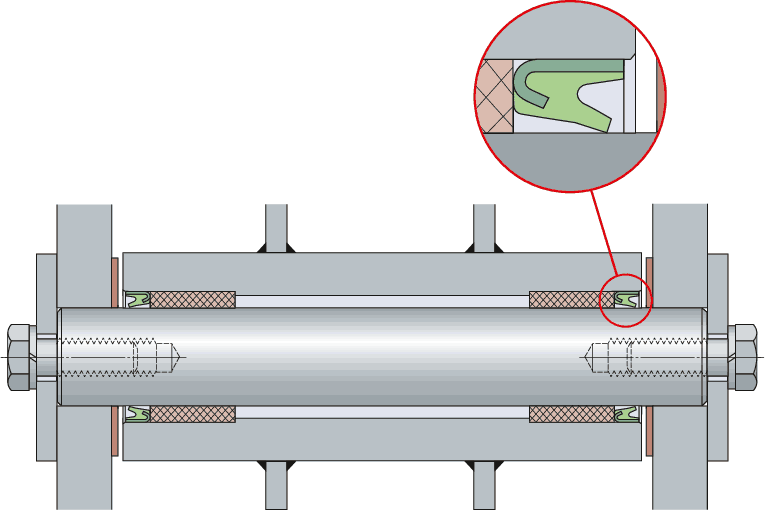

Sealing solutions

Filament wound bushings have only a limited capacity to accommodate solid particles embedded into the filament wound material. Therefore, seals can significantly increase their service life when the bushings are to be used in highly contaminated environments. Contaminants otherwise damage the strands of the sliding surface layer and the continuing destruction of the structure of the sliding layer would result in rapid increase in wear. SKF recommends using SKF wiper seals, which allow the same sliding velocities as the filament wound bushings, to protect the sliding surface against the ingress of abrasive contaminants.