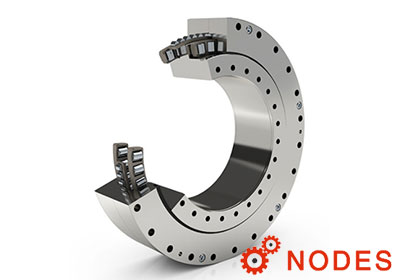

Mounting arrangement

A widely used method of attaching Kaydon slewing ring bearings is to bolt through both races with fasteners spaced uniformly around the entire mounting face. It is recognized, however, that the equipment designer cannot always accommodate this type of arrangement and may require tapped holes and even special bolt patterns for assembly and maintenance reasons.

The designer is responsible for the mounting arrangement and validating the design.

Weld rings are another option for attaching one of the slewing ring bearing rings to its mating structure. The bearing is furnished with a low carbon steel weld ring or band welded to one race. The weld ring can then be welded to the machine without damage to the bearing, provided proper precautions are taken.

Welding the bearing, or welding near the bearing, can damage the bearing.

Lubrication

Grease is the typical lubricant used for slewing ring bearings. Periodic application of fresh lubricant into the bearing is required to reduce friction and wear, provide corrosion protection, displace contaminants, and enhance performance of the seals. One or more grease fittings or lubrication holes are provided in all slewing ring bearings for this purpose. Additional lube fittings or holes may be required and can be furnished on request.

Whenever the Kaydon slewing ring bearing has an integral gear, it too requires periodic application of grease for optimum performance.